This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- Types of converters used in hybrid-electric propulsion systems for electric aircraft.

- What is a starter generator?

- Powertrain options for more-electric-aircraft (MEA) designs.

This article will take a deep dive into challenging, but innovative, high-power-density development technologies for electric aircraft that will significantly reduce noise and fuel-burning emissions in the atmosphere.

The aircraft industry is striving to lower operating and maintenance costs plus reduce gas emissions as they move toward a hybrid electric aircraft (HEA), the more electric aircraft (MEA), and ultimately the all-electric aircraft concept. Let’s begin with the HEA.

The HEA concept greatly extends the MEA idea by electrifying the aircraft propulsive power coupled with the auxiliary aircraft power system. This effort will push the limits of the envelope of aircraft electrification.

Hybrid-Electric Propulsion Systems

Designers are using their knowledge and creativity to enable hybrid-electric propulsion, especially for larger commercial aircraft. A megawatt-class, lightweight, high-efficiency, high-density electric power system will be needed for increased performance and low carbon emissions.

High-Power-Density Converters for HEA

Electric aircraft propulsion designs will need to have higher fuel efficiency and lower noise pollution, in addition to much lower carbon emissions. One possible way to achieve these goals is to use a high-power-density, medium-voltage (MV), megawatt-level power converter.1 The architecture for this effort is based on a hybrid design consisting of a three-level, active neutral-point-clamped (ANPC) topology.

The optimal way to achieve both high efficiency and high power density is for power designers to significantly increase the dc bus voltage level from the present 270 V dc to a higher 2 kV dc. This higher voltage will enable smaller, lighter electric cables that run from the power converter to the electric propulsion motor.

In addition, designers will need to boost the power converter’s fundamental frequency from 400 Hz to greater than 1 kHz. Consequently, the design also will require a higher-switching-frequency power converter.

The best power transistor element for such a design would be to use silicon-carbide (SiC) MOSFETs in the design architecture along with superior SiC gate drivers.2

Using SiC devices, an optimized filter design, and an improved mechanical packaging will improve both efficiency and power density. The final design is a SiC/Si hybrid for a 3L-ANPC power converter. The inverter design achieves a high efficiency of 99.1% and high power density of more than 18 kVA/kg and 10 MVA/m3 at nominal operating conditions.

High-Power-Density 4-MW Generator for HEA

Presently, traditional air transport systems don’t meet any reasonable level of green-mode transportation. The European Union has a Flightpath 2050 program that’s trying to reduce carbon-dioxide (CO2) and nitrogen-oxide (NOx) emissions per passenger kilometer by 75% and 90%, respectively, relative to the turn of the New Millennium.

One development underway is the E-Fan X ground demonstrator in a joint effort by Airbus and Rolls-Royce. It’s a hybrid-electric propulsion system with a 2-MW electric drive powered from a 2.5-MW generator, which, in turn, is powered by a gas turbine located in the aircraft fuselage. Ground testing is continuing at present.

What’s next?

Making a hybrid-electric aircraft fly involves continuous power density and efficiency of the electrical machines that will help enable aircraft propulsion and generation. Both propulsion and generation need to be pushed beyond the present state of the art, though.

At this point, the Mark#1, 2.5-MW permanent-magnet (PM) generator seems to be the best promising idea so far. The next level of a higher-power generator will be challenging. However, there’s an ongoing concept of a 4-MW (or 5-MVA), 15,000-rpm generator that’s striving to achieve 18 kW/kg, which would be a new record level of performance.3

Electric-Aircraft Power Electronic Converters

Power density is critical in aircraft power electronic converters (PECs).5 Low weight and high power capacity in electric aircraft are paramount as key objectives. Simply increasing the speed of the PEC will not always be effective in boosting power density. Higher frequencies can lead to significant increases in iron and ac copper losses, along with higher requirements for PEC performance, which will negatively impact weight and size.

The maximum power of the wound-field synchronous machine (WFSM) can reach 250 kVA. An example is four equally rated WFSMs in the Boeing 787 Dreamliner architecture. Total electrical power is 1,450 kVA (this includes additional power generation facilities as well). Two variable-frequency starter generators (VFSGs) on two of the primary engines were included in this power estimate.

A variable-speed variable-frequency (VSVF) power system (i.e., ‘‘frequency-wild ac system’’) seems to have attracted lots of interest. The first commercially available implementation of this system uses four 120/150-kVA variable-frequency (VF) generators in the Airbus A380 platform. The VSVF technology also is being deployed on the Boeing B787.

On top of that, a proposal of a “variable-voltage” bus strategy may enhance the overall power-management system. A competing dc-bus topology has been proposed as well, with 540 V and 270 V for some alternative aviation technologies.

Electric Aircraft Starter Generators (S/G)

More-electric functions, like integrated, high-power-density, starter-generator designs,5 will be key technologies in the future more-electric-aircraft (MEA) system design. Gas turbines are being configured to perform electric starting (aka engine cranking) via electrical machines (EMs), that in turn will harvest mechanical power from the engine in the generator mode. This will enable elimination of hydraulic and pneumatic systems.

MEA Electric Powertrains

The Ultimate Goal: All-Electric Powertrain

In this future design concept, a set of battery energy-storage devices will be the only energy source. This design leads to zero emissions. To make this concept a reality, better state-of-the-art energy-storage devices will be needed. Stay tuned.

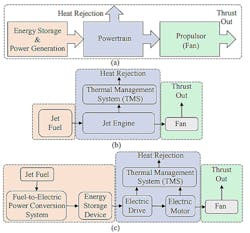

The Hybrid-Electric Powertrain

In this concept, onboard aircraft energy will be supplied via jet fuel and electric energy-storage devices (see figure). With such a system, aircraft propulsion may be performed via both electric motor and jet engine.

The Turboelectric Powertrain and Distributed Propulsion

The turboelectric powertrain architecture has two sub-categories: full turboelectric and partial turboelectric. Both architectures don’t require energy-storage devices in their design. As a result, state-of-the-art ac-ac power converters could be used to interface the two machines and eliminate dc-bus electrolytic capacitors that are prone to fault problems. Just like the Series Hybrid Powertrain architecture, the full turboelectric topology implements an electric motor as the propulsion device.

With this method, the motor is powered by the electric energy provided by the onboard, high-power-density electric generators, which are in turn driven by the jet engines. Alternatively, the partial turboelectric architecture uses the jet engines and electric motors to provide propulsion power.

NASA: Green Aviation

NASA’s Ames Research Center supports key missions in aviation science and technology. Green aviation has a goal to improve aircraft fuel efficiency and develop new technologies and systems engineering processes that can achieve a future of carbon-neutral air transportation across the globe.

NASA’s goal is to take responsibility for the impact of aviation on the environment. This will include reducing carbon footprint and other harmful emissions, as well as noise. MEA is beginning to use electric powertrains.

Summary

Aircraft electrification will greatly reduce the carbon footprint in air travel. Airlines are slowly getting away from jet-powered aviation and will begin to roll out battery-powered electric aircraft in the future. In the interim, some commercial airlines are partially deploying HEA.

High-power-density aircraft generators are methodically being deployed on HEA and ultimately on the MEA. NASA efforts will help speed up the introduction of HEA and MEA as we progress into the future of aviation and ultimately move toward the all-electric aircraft.

Read more articles in the Power Management Series: Delving Into Power Density

References

1. “High Power Density Medium-Voltage Megawatt-Scale Power Converter for Aviation Hybrid-Electric Propulsion Applications,” 2019.

2. “IGBT & SiC Gate Driver Fundamentals,” Texas Instruments 2021.

3. “4-MW Class High-Power-Density Generator for Future Hybrid-Electric Aircraft,” IEEE Transactions on Transportation Electrification, Vol. 7, No. 4, December 2021

4. “Toward More Electric Powertrains in Aircraft: Technical Challenges and Advancements,” CES Transactions on Electrical Machines and Systems, Vol. 5, No. 3, September 2021.

5. “High-Power Machines and Starter-Generator Topologies for More Electric Aircraft: A Technology Outlook,” July 24, 2020.