Download this article in PDF format.

It’s okay to start using gallium-nitride (GaN) devices in your new designs. GaN transistors have become extremely popular in recent years. These wide-bandgap devices have been replacing LDMOS transistors in many power applications. For example, GaN devices are broadly being adopted for new RF power amplifiers used in cellular base stations, radar, satellites, and other high-frequency applications. In general, their ability to endure higher voltages and operate at frequencies well into the millimeter-wave (mmWave) range have them replacing traditional RF power transistors in most amplifier configurations.

Now, GaN devices are showing up in power applications such as switch-mode power supplies. Their lower on-resistance and faster switching times provide significantly improved efficiency.

Semiconductor companies have also found new ways to make GaN devices on silicon-carbide substrates and on the even lower-cost silicon substrates using standard processing techniques, which of course cuts costs overall. In addition, enhancement-mode devices are now available, as well as the original depletion-mode high-electron-mobility transistors (HEMT), becoming attractive options for designers in many more products.

While the popularity of GaN devices continue, a critical parallel effort is underway to find and develop a comprehensive methodology to qualify the reliability of GaN products. For rugged military equipment and critical industrial gear, reliability is a key deciding factor in the use of GaN versus legacy silicon devices for any new power product. Here’s what one company is doing about this.

Sponsored Resources:

- A comprehensive methodology to qualify the reliability of GaN products

- Does GaN have a body diode?

- Thermal considerations for Designing a GaN Power Stage

QA on GaN

Texas Instruments has developed a comprehensive quality program to validate the reliability of its GaN products. After years of developing such programs for silicon devices, engineers are applying the principles they have learned to determine just how long a GaN device will last under a variety of conditions encountered in different use cases.

Reliability and quality are commonly determined by performing standardized tests. The reliability is extrapolated from test data collected on failure modes. A key part of the evaluation process is using statistical and other mathematical methods to predict things like failure rate and lifetime.

Designers want to use GaN devices because of their impressive characteristics and features, thereby gaining a competitive advantage in the marketplace. They also want these products to be able to pass the tough testing of the two main standards bodies, which have the last word: the Joint Electron Device Engineering Council (JEDEC) and the Automotive Engineering Council (AEC).

The two groups’ testing procedures for certification usually fall into one of three categories: electrostatic discharge (ESD), device, and package. Texas Instruments has developed a quality program to provide reliable GaN solutions based on GaN fundamentals and the relevant testing.

Critical Design Considerations

GaN power transistors are now showing up in variety of power supplies, inverters, dc-dc converters, and motor controls. Two important factors in the design are thermal performance and switching characteristics. Good thermal design is an essential part of the solution, as it determines the failure rate and lifetime of the device. Thermal considerations also affect the packaging and attendant mechanical structure of the product, as well as the need for forced cooling. Heat sinks are typically required and the thermal conductivity through the PCB must be the best.

As for switching performance, GaN devices must be able to switch reliably with inductive components and paths. All switch-mode power supplies use multiple inductors for energy storage and are effective in that role. But the stress they place on the switching transistors is significant. Even the inductance of overly long PCB traces can cause problems. And this switching usually occurs at high current and voltage levels.

Does GaN Have a Body Diode?

Virtually all silicon power MOSFETs have a body diode—a diode connected between the source and drain. GaN transistors do not. The internal structure is such that this diode doesn’t exist, nor does the attendant reverse-recovery charge. With no reverse-recovery losses, GaN devices switch faster.

However, GaN transistors do exhibit a diode-like behavior in reverse-current conduction. Known as third-quadrant operation, this diode effect is useful in implementing rectifiers.

TI GaN Products

Texas Instruments has a versatile line of GaN power products. One example is the LMG3410R070 power stage, 600-V transistor with an integrated gate driver. This device has ultra-low input and output capacitance and zero reverse recovery. It works well in bridge and half-bridge configurations. And as mentioned above, with no body diode, there are no reverse-recovery losses.

Texas Instruments’ LMG341xR070 features a 600-V GaN transistor with 70-mΩ on-resistance. The internal gate driver has only 20-ns propagation delay and a 25- to 100-V/ns adjustable slew rate.

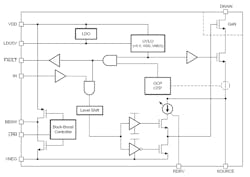

The figure shows the functional block diagram of the LMG341xR070 GaN device. The integrated gate driver simplifies its application. The device is also loaded with internal protection circuits like overcurrent protection (OCP), overtemperature protection (OTP), undervoltage lockout (UVLO), and transient overvoltage immunity. No external protective devices are needed. The device comes in an 8- × 8-mm QFN package and requires a 12-V power supply.

As for applications, this device fits well within a wide range of power supplies, converters, solar inverters, UPS, and battery chargers.

Some similar, but lower-voltage, ICs are also available. These are the LMG5200 and LMG1210 half-bridge devices, both of which have internal gate drivers. Potential applications include dc-dc converters, class D audio amplifiers, and motor drivers.

Sponsored Resources:

- A comprehensive methodology to qualify the reliability of GaN products

- Does GaN have a body diode?

- Thermal considerations for Designing a GaN Power Stage

Related Reference: