>>

Website Resources

..

>> Library: TechXchange

.. .. >> TechXchange: Power Management

.. .. .. >> Topic: Energy Harvesting

Semiconductor technology follows many trends, one of which is the consistent reduction in active power for a given function from one generation to the next. If it wasn’t for this trend, we may never have “discovered” energy-harvesting solutions as a practical alternative to conventional power. The relatively small amounts of power that can be scavenged using existing energy-harvesting technology is meager but, under the right conditions, it’s more than enough to enable a wide range of Internet of Things (IoT) applications.

Sensor nodes in the IoT are perhaps the ideal use-case for energy harvesting, but it still requires a leap of faith to move away from a known and reliable power source like a battery or offline, to something that’s far less tangible. However, just as the availability of ultra-low-power digital solutions has reduced our dependence on power, the technology involved with energy harvesting has improved.

Solar panels are more efficient, the amount of energy generated through thermal and motion scavenging is increasing and, perhaps more importantly, the power-management ICs now addressing ultra-low-power applications ensure that more of the harvested energy can be put to good use. So, it seems like it may be time to debunk some of the myths around energy harvesting and why it can’t be a practical alternative to conventional power sources.

1. Energy harvesting is expensive.

Some may believe that energy harvesting is an expensive design choice, but consider the total system cost of the alternatives. Batteries need space, as well as some form of clip to mount and retain them, or at the very least a dedicated terminal and leads. Offline power is even more needy, in the form of an ac-dc converter. This normally involves a transformer of some kind, which are both bulky and costly.

Energy-harvesting devices are often small and unobtrusive and can present a lower system cost overall than the alternative. However, they also reduce the total cost of ownership, because there are no batteries to replace (with the associated service visit) and no AC power to supply (with the associated cabling and certification).

The design costs are also likely to be lower, particularly if the alternative involves an ac-dc converter, as these can be notoriously difficult to design if the aim is to achieve the most cost- and performance-optimized solution. From a maintenance point-of-view, if the device doesn’t rely on an auxiliary source of power—either offline or battery—then there’s less chance of a failure in service, which keeps service costs down for the supplier and customer satisfaction up.

2. Energy harvesting is fine in principle, but hard to implement in practice.

Depending on the harvesting technology used, your engineers may need to adapt their design approach. It will be necessary to think about how the transducer will be exposed to whatever form of energy it’s harvesting. But once that’s done, an application that uses harvested energy is essentially maintenance-free, so it becomes a “fit and forget” experience. That means they can be fitted almost anywhere and designed to any form factor with little or no compromises.

Any design that uses offline power will also need to be designed with the power source in mind. In addition, it will need to comply with strict safety regulations and take accessibility into consideration, which can impose much more significant design constraints. In terms of accessibility, the same is true for battery-powered devices, as the enclosure will need to feature access portals for battery replacement.

3. The aesthetics of the end application will suffer.

For the same reasons mentioned above, using a reliable and essentially inexhaustible form of power opens up huge potential from a product design point of view. The transducer can become a feature of the design, or be hidden from view. Access portals become a thing of the past, because there will be no need to access the inside of the product.

Now think about devices powered from secondary cells. These need regular recharging, which means unless they use wireless coupling, they will need a connector somewhere on the outside that’s accessible to the user. A charging portal presents a point of ingress for dirt, dust, and water. Depending on the application, this imposes further demands on the PCB and its components, to protect it from this potential ingress. Furthermore, any port that receives power typically needs some form of protection, in the form of additional components and additional BoM cost.

4. Harvesting energy is unreliable.

Reliability of supply can cause anxiety. But in truth, if a device uses solar power, we can rest assured the sun will always come out. More seriously, the key to removing supply anxiety with energy harvesting is to design it with the use-case in mind and choose the most appropriate form of harvesting transducer. These are increasingly varied and now include switches that generate power from its actuation, using a small coil and magnet employing electromagnetic induction.

Coupled with a suitable power-management IC and capacitive storage, a single actuation can generate around 0.3 mW. In a similar way, transducers may be attached to moving objects, such as a door, to harvest even greater levels of power. The Peltier effect is used in semiconductor-based transducers to generate energy from temperature gradients, which exist everywhere. Vibration, light, heat, and even RF radiation are now reliable sources of energy ready to be harnessed.

5. You can’t generate enough energy for wireless applications.

Until recently, that may have been true, but technology marches on. The latest version of the Bluetooth Low Energy (BLE) specification is particularly pertinent to ultra-low-power applications, and semiconductor solutions are now available that embrace this recent innovation. Bringing these developments together with an energy-harvesting switch has already been demonstrated.

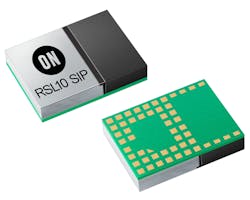

The amount of power generated is enough to supply a device like the RSL10 SIP, a complete system-in-package (SiP) solution featuring BLE connectivity and a fully integrated antenna. A single press can produce enough energy to enable the RSL10 SIP to register the switch actuation, take measurements from any additional sensor(s), process the data, and transmit it to a Bluetooth gateway every time it’s actuated. It’s a great example of how energy harvesting can be totally reliable in an IoT application.

Bluetooth Low Energy switch board.

Similarly, the KNX RF protocol has demonstrated the same capability to communicate battery-free. Zigbee Green Power is amazingly robust to transmit On and Off commands at a range of up to 30 meters indoors with just a switch pushbutton.

6. Energy harvesting takes up more space.

Now, it’s fair to point out that an energy-harvesting switch is probably larger than a regular switch. But in terms of the total system, you’re still winning because you don’t have to factor in the space required for AA or AAA batteries, or a power transformer. Many of the newer solutions are intended to be unobtrusive, which also opens up new opportunities in product design as discussed earlier.

Thermoelectric transducers can measure just a few millimeters in thickness and be attached between a heatsink and the inside of a metal enclosure, completely out of sight. In this way, they add barely any additional thickness and provide what’s essentially a free source of energy from otherwise wasted heat. Think of it as regenerative braking for embedded electronics.

7. It’s really hard to do.

Another consideration engineers may have when thinking about energy harvesting is the design burden—is it difficult to use? The good news here is that it’s getting easier every day. Take the switch example above; the switch used in that application is a fully integrated “Plug & Play” solution. It comes from a company specializing in the design and manufacture of conventional switches and sensors, but it saw an opportunity to integrate its expertise and move into the area of energy harvesting.

ON Semiconductor's RSL10 system-in-package.

Semiconductor manufacturers are increasingly turning on to the idea of energy harvesting with new solutions coming to market all the time. One of the most common energy-harvesting solutions—LED garden lighting—is also one of the best examples of design simplicity. These devices require only a simple solar cell, storage capacitor, and a power-on-reset generator to enable wireless sensor communication.

8. It will impact the end user’s experience.

If that’s true, then it can only be in a positive way. Wireless technology is still seen as mystical, so imagine a customer’s reaction to an electronic device that doesn’t need to be plugged in and never needs its batteries changed. Displays based on electronic ink are another recent innovation; they only consume power when the display is changing, but need no power to sustain whatever is on the display. Couple one of these to an energy harvester and some ultra-low-power electronics, and you have a product that’s always on, always up to date, and always telling you what you need to know. If that’s not a positive user experience, I don’t know what is.

9. It just puts the burden of energy somewhere else.

This is an interesting point because we’re all more aware of the environmental cost of using energy, but do we really appreciate our energy’s journey? It starts at a power station and ends with our electronic devices, but the intermediate stages all incur losses. Energy harvesting generates power at the point of use, with fewer (if any) intermediate (lossy) steps between generation and consumption.

10. It’s not required by law.

While there’s no obligation to use harvested energy in place today, there are legal requirements about how energy is used in general, and how limited resources are consumed and recycled. This extends to a range of directives that impact the electronics industry, which ultimately reach the consumer in a trickle-down way.

But why wait for legislation? Adopting energy harvesting has many upsides, including making end products more sustainable and therefore attractive to the market. Without sounding too opportunistic about it, why let your competitors be the first to establish themselves as the environmentally friendly manufacturer when that title is within your reach?

11. It’s not a 24/7 solution.

Hopefully the preceding discussion has demonstrated that harvested energy is about more than catching glimpses of direct sunlight through a cloudy sky. There are so many ways to scavenge energy from the environment that it would be harder to point to an energy-harvesting transducer that doesn’t work 24/7. They are, by default, autonomous devices; they simply need to be exposed to the environment to start generating energy.

Energy harvesting is rapidly becoming an important part of sustaining the IoT, by putting the source of energy right at the point of use. Not only does this reduce the burden on power generation in general, it also reduces our reliance on batteries, which present their own carbon footprint. As the number of IoT endpoints increases to the many billions, we can expect energy harvesting to become even more integral to tomorrow’s connected world.

Bruno Damien is Marketing Director of IoT for the EMEA region at ON Semiconductor.

>>

Website Resources

..

>> Library: TechXchange

.. .. >> TechXchange: Power Management

.. .. .. >> Topic: Energy Harvesting