Many test systems today are based on PXI, which offers a whole test system in one frame. PXI gives you high speed, small size, vendor interoperability, and a wide variety of available cards. But for dc power supplies, being squeezed into a PXI slot can pose a real challenge.

Related Articles

- Do You Have Enough AC For Your DC?

- What Is An Autoranging Power Supply?

- Capacitors Create Challenges When Modulating DC Power

At low output power, perhaps up to 20 W, it makes a lot of sense to put the dc power supply inside the PXI mainframe to take advantage of the compact mechanical environment and common communications. But when the output power gets larger, it becomes harder to host a dc power supply within a PXI mainframe.

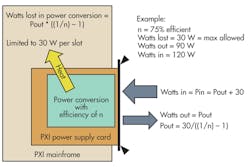

Even an efficient dc power supply card will only be able to source a fraction of the up to 30 W of limited power per slot from the PXI backplane (see the table). That difference in power between input power from the backplane and dc output power is lost as heat on the PXI card. Since the PXI mainframe can only support 30 W of cooling per slot, the dc power supply card is also constrained by cooling.

The trend, though, is to get more dc output power out of a PXI power supply card. Manufacturers are trying several approaches to overcome the limited power and cooling per slot.

This file type includes high resolution graphics and schematics when applicable.

New Solutions

One approach is to build a more potent PXI mainframe that has beefier supplies and extra cooling per slot so more power-hungry and heat-producing dc power supply PXI cards can be used. However, this approach defeats PXI interoperability, as these more power-hungry, heat-generating power supply cards will only work in these special PXI frames.

The next approach is to relieve the burden on the PXI mainframe’s backplane supply by powering the dc power supply card directly with ac or dc power via the card’s front plane. Cards that use an ac input are less common because the ac power conversion circuitry tends to take lot of space. Since the ac components don’t tend to fit nicely on a thin PXI card, these vendors sell multi-slot cards. While this solves the problem, it mitigates the small size benefit.

Driving the dc power supply card with dc power from the front plane is a more common solution. These PXI cards are effectively programmable dc-dc converters. Putting 24 V dc or 48 V dc into the front plane does create a bit of a configuration hassle, as it means you must have some kind of auxiliary dc source outside of the PXI mainframe but still in the ATE system.

Often, this auxiliary dc source is an ac-dc power brick like those that power and charge laptops. While the cost is low, this brick-charger needs to be mounted somewhere within the test system with a wire run to it. This is not a terribly difficult mechanical configuration to manage, but it does defeat the benefit of a whole test system in a frame.

Providing ac or dc into the PXI dc power supply card does overcome the limited power available from the PXI mainframe’s backplane power supply, but this approach has its limits based on the efficiency of the dc power supply card. All of the heat generated by the inefficiencies of the PXI power supply card must be dissipated and therefore limited to 30 W per slot (Fig. 1).

If the PXI power supply card is a linear power supply, the typical efficiency is less than 50%, limiting the total output power to 60 W or less. If a switching power supply or some other efficient design is used, you can get more power output, but even efficient designs will be limited to 100 W to 200 W of output power. By having the power supply take up more than one slot, you can accumulate the available power per slot and the available cooling per slot.

However, while this solves the power and cooling, it does increase the size and raise the cost of the solution, as there is a per slot mainframe overhead cost that needs to be considered. You may also have to consider how the heat generated on the power supply cards could cause thermal drift problems on nearby cards. Additionally, there could be issues with magnetic or radiated interference from noisy high-power conversion circuits packed in a frame close to sensitive RF cards.

So while vendors can offer you solutions for higher output power, you need to watch out for compromises in size, cost per slot, interoperability, mechanical complexity, and nearby card performance.

There is another way to configure a system that can provide more dc power. For higher power and higher point count, a complementary solution like the Agilent N6700 modular power system makes sense (Fig. 2). While a complementary solution is not a pure PXI system, by moving the power supplies out of the PXI frame, you are no longer limited in size, power, and cooling.

Dedicated power supply solutions such as the Agilent N6700 can offer very small sizes (up to four dc outputs in 1U of rack space) and lots of power (up to 500 W per output) in a mainframe that is optimized for power and cost, leaving the PXI frame for instruments that can be efficiently packed onto a small PXI card and take advantage of the fast backplane communications of PXI.

Bob Zollo is a product planner with the Power and Energy Division, Electronic Measurements Group, at Agilent Technologies. He is responsible for creating Agilent’s power products roadmap by researching customer and industry trends and developing product plans to meet emerging customer needs. He holds a degree in electrical engineering from Stevens Institute of Technology in Hoboken, N.J. He can be reached at [email protected].