This file type includes high resolution graphics and schematics.

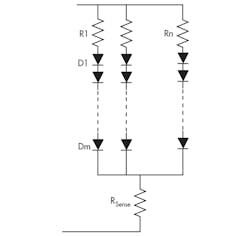

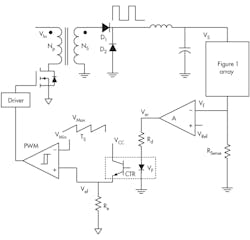

LED-based lighting is replacing incandescent and gas-discharge lamps in many situations. As practical lighting sources, and considering their directional nature, LED fixtures usually use multiple LEDs arranged in an array, with “m” LEDs in a serial string and “n” such strings in parallel (Fig. 1).

For the array configuration and the exponential I-V characteristics model of a single LED,1 it’s also possible to have a similar model representing the loading of such an array.

Related Articles

- Master The Fundamentals Of LED Illumination

- Generate Realistic Models For LED Current Versus Voltage

- Use Flyback Converters To Drive Your LEDs

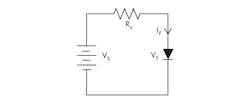

Since the single LED is a diode with a nonlinear forward-voltage/current, driving it with a fixed voltage source is generally not recommended. Rather, a serial (current-limiting) resistor is needed to equalize the power source and the load,(Fig. 2).

However, sizing this resistor requires a significant analytical manipulation. Using the single-LED exponential model, a Kirchoff’s voltage law (KVL) equation around the circuit loop gives:

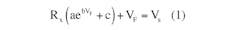

which can be rearranged to:

where a, b, and c are model parameters for a selected LED, as defined in the reference.

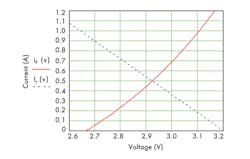

This is a challenge to solve symbolically, but it can be solved numerically with mathematical software tools. Alternatively, it can be solved graphically by separating the two key I-V relationship equations, v+ RxIF = Vs and IF = aebv + c.

For example, using a Lumileds Luxeon Rebel ES LED with a 3.2-V dc source and a desired drive current of 0.5 A, the horizontal current line intercepts the LED curve at 2.92 V (Fig. 3). Therefore, the series resistor will be Rx = (3.2 – 2.92)/0.5 = 0.56 Ω.

However, the graphical approach would not handle an LED array effectively, and the numerical method works better. To represent the array current iA, the exponential model for the (m × n) array is modified, since voltage drops across current-limiting resistor Rn and sense-resistor RSense are usually small compared with driving-source Vs:

With the array model, the switch-mode buck-regulating current driver in a closed-loop configuration (Fig. 4) can be described by a set of equations starting at the feedback point, circling around the control loop, and ending at the driver output:

• Current sensing:

Vf = iA • RSense (4)

• Error amplifier:

Ver = A(VRef – Vf) (5)

• Effective error:

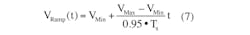

VRamp(D • Ts) = Vef (8)

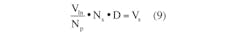

• Power stage:

Reference

1.“Generate Realistic Models for LED Current Versus Voltage” Keng C. Wu; Electronic Design, Vol. 61, No. 1, p. 52, Jan. 10, 2013, http://electronicdesign.com/power/generate-realistic-models-led-current-versus-voltage

This file type includes high resolution graphics and schematics.