Since the late 1990s, the 18650 lithium-ion rechargeable cell has been a common standard cell used in many devices and a host of applications. Like the ubiquitous AA, AAA, C, and D alkaline primary cells we use every day in flashlights, toys, radios, and practically anything that’s powered from a one-time use battery, the 18650 is found everywhere in rechargeable applications. These range from electric vehicles (where a single car will use thousands of 18650 cells), to power tools, to laptops, to personal electronics, and medical devices. In fact, NASA uses 18650 cells in its space-suit designs.

Why are 18650 cells so popular? A key reason is standardization. Certainly, the chemical formulations, internal construction, and manufacturing methods have evolved in the last 20 years, yielding better cells with higher capacity and longer cycle life. What hasn’t changed is the size of the cell. The 18650 cell is 18 mm in diameter and 65 mm tall; hence, its name 18650.

Other cell form factors have standard sizes, too, but even though they’re standardized, many alternate cell designs haven’t achieved the same popularity. If the cell size never becomes popular, it can hardly be called a standard.

Conversely, as more and more applications are using 18650 cells, the 18650 has become one of the most popular sizes of cells and is clearly a global standard. When the cells are used so commonly, many cell manufacturers will offer this size. That drives competition, especially in terms of cost, and a variety of sources with a wide span of product quality become available.

Going the Rechargeable Route

When an engineer seeks to develop a battery-powered device to run from a rechargeable battery, first the engineer must assess the current that will be drawn by the device, as well as the desired run time, and then calculate the capacity of the battery. From there, the engineer will decide on a battery design: a single cell that can provide 3 to 4 V to the host device, or battery pack that will provide voltage, current, and capacity beyond that of a single cell. Once a battery configuration (cell or pack) is decided upon, the engineer must then select a size for the cells.

The 18650s are commonly selected because of good energy density and a reasonable size and capacity. So, once the cell is selected, the mechanical engineers can design the cell holder or battery pack to accommodate one or more 18650 cells. Since it’s a standard size, the mechanical engineers can design the device to hold any vendor’s cells if the cells are 18650s. The engineers can then turn to selecting the best 18650 cell for the application, considering each cell vendor’s price, delivery, and performance of their cell in the application.

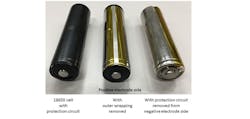

1. Shown are the various types of 18650 cells available.

This design process is made possible because the 18650 cell is always 18 mm wide by 65 mm tall. They are a standard size, aren’t they? As it turns out, not all 18650 cells are 65 mm tall (Fig. 1).

2. Unwrapping an 18650 that includes a protection circuit.

Some cells are taller because they contain a protection circuit. This protection circuit adds a few millimeters to the length of the cell, making it slightly taller than 65 mm. These cells are 18650 cells, so you would expect them to all be 65 mm tall. However, they clearly aren’t all the same size (Figs. 2 and 3).

3. The 18650 is shown with and without the protection circuit, revealing the detail of the protection circuit.

In some applications, the 18650 cells are installed in a cell holder with spring-loaded contacts or flexible metal contacts. If there’s enough travel in these contacts, then the slightly larger “18650” will fit. But if the cell holder has tight tolerances, then this extra-long “18650” cell would not fit into the device.

Summary

The 18650 cell is an extremely popular standardized rechargeable cell. It’s called to duty in many designs. However, some 18650 cells contain protection circuits, which increase the length of the cell and could make it unsuitable (too large) for the intended application. So, be sure to check the dimensions of the cell before you select it for your design.