Members can download this article in PDF format.

Reliability of the power-conversion system is a critical issue, especially at high power levels. Application areas that fall under this umbrella include solar-powered inverters, motor drives, electric vehicles (EVs), dc-dc converters, traction inverters, and more. Thus, designers must address the ever-growing need for an improved, reliable fault-detection system in high-power systems.

Redundant components, as well as greatly over-rated power switches, have traditionally been used in designs to improve the reliability of the overall system. However, such solutions greatly increase system complexity and cost.

Sponsored Resources:

- Addressing the growing needs of fault detection in high-power systems

- Using isolated comparators for fault detection in electric motor drives

- Isolated zero-cross detection circuit

As a more effective solution, fault-protection strategies will maximize the use of power-device capabilities without compromising their reliability. Implementing fault-protection systems as a part of the gate-drive circuitry will help prevent power devices from being damaged in the event of a system malfunction or over-stressed occurrence.

Let’s look at some methods used in more modern, effective fault-detection designs using comparators.

Fault Detection in High-Power Systems

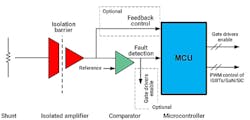

Designing fault-detection circuitry may require the use of standard discrete devices such as comparators, a discrete isolation amplifier, and a microcontroller unit (MCU).

An overcurrent fault detector can be composed of a basic shunt current sensor circuit at the isolation amplifier input, which will trigger a fault-detection alarm via a comparator when the flow of current through the system exceeds a set reference limit. The MCU immediately takes any action necessary to protect the system during a fault by disabling the power gate drivers (see figure).

Typically, the worst-case scenario propagation delay for overcurrent detection can be less than 1 µs, depending on the speed of the comparators and digital isolators selected by the designer. In turn, discrete implementations like that illustrated in the figure can be built.

However, that architecture will take up more printed-circuit-board (PCB) space, and it can become expensive for designs requiring higher accuracy. Using a more integrated solution with a smaller board footprint may be a better option in terms of cost.

The overall design architecture in the figure raises an alert when the flow of current through the system exceeds a certain limit.

Other design architectures for fault-detection design may include:

- Standard comparators and digital isolators

- Isolated comparators

- Isolated amplifiers

- Isolated modulators

- Isolated discrete designs

Most of the devices listed above can be found in integrated form. However, some designers may want to use discrete design architectures for various reasons.

Isolated Comparators for Fault Detection in Electric Motor Drives

Electric motor drives typically have a variable-frequency output signal that will enable an electric motor to power an industrial load. This type of motor can drive loads such as heating and air-conditioning systems, compressors, elevators, and various factory-automation loads, just to name a few.

Due to high temperature and humidity, ac power-line variations, and mechanical drive overload conditions, electric motor drives may experience many kinds of fault events during their lifetime.

Typical electric-motor-drive fault events can be classified as:

- Shoot-through: This is caused by adjacent power switching transistors that may turn on simultaneously due to EMI or phase-to-phase short-circuit events.

- Overvoltage conditions: These may occur due to back-injection from the motor to the dc-link rail during braking, poor regulation of abnormal ac power loads, wiring errors, or even insulation failures.

There are many ways to provide adequate and reliable protection for motor drives. Since we are discussing comparators in this article, the discussion will focus upon those types of devices.

One such group of devices, containing comparators, is the Texas Instruments AMC23Cxx family (where xx stands for 10, 11, 12, or 14). These devices have low-latency and contain reinforced isolated comparators, which will quickly leap into action during short-circuit current, overcurrent, undercurrent, overvoltage, undervoltage, and overtemperature fault-detection scenarios. The AMC23C14 is a key part of this family.

These comparators have integrated, adjustable threshold functions. This family also has a high-side, low-dropout regulator for the power supply, with a fast response time less than 0.5 µs.

Isolated Zero-Crossing Detection Circuits

A zero-crossing detector circuit changes output state when the ac input crosses the zero-crossing reference voltage. This design features a single-chip solution for the isolated zero-crossing detection of an ac sine wave, with inverting and non-inverting digital outputs.

TI’s AMC23C10 also can be used for this important kind of zero-crossing fault detection. The IC is actually a precision, isolated comparator with a very short response time, which makes it perfect for zero-crossing detection of high-voltage signals. This comparator also will galvanically isolate the low-voltage circuits from the zero-crossing high-voltage circuitry.

The comparator device barrier is certified to enable reinforced galvanic isolation of up to 5-kV RMS according to VDE V0884-11 and UL1577 isolation standards, and it supports a working voltage of up to 1 kV peak.

As we move forward to improve future system reliability for high-power fault detection, we will see many more advanced integrated solutions by Texas Instruments that will enable certified, accurate, and quick fault detection in high power systems.

Sponsored Resources: