LEDs have come a very long way in performance and “comfort factor” in the past few decades for many good reasons. At the same time, the basic ac-line LED “supply” consisting of an ac/dc voltage-output regulator and current-limiting resistor, or perhaps somewhat controllable current source but not much else, is no longer sufficient or acceptable, also for many good reasons.

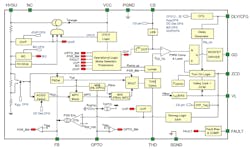

Clear evidence of the level of these raised expectations is shown by the HVLED101 from STMicroelectronics and its 36-page detailed datasheet. This 90- to 400-V flyback controller for LED-lighting applications delivers up to 180 W while enhancing performance and simplifying design through extensive feature integration, patented control techniques, and support for primary-sensing regulation (Fig. 1).

What’s a Flyback Controller?

Not familiar with the flyback controller concept? It’s a buck-boost converter with the inductor split into two windings to form a transformer, so that the voltage ratios are multiplied with an additional advantage of isolation. It has been around “forever” and was extensively used in the power subsystem in higher-voltage consumer products such as venerable CRT TVs. It’s now used in many ac/dc “wall wart” adapters.

The “flyback” name is due to the sudden stop/stop, on/off action of the MOSFET switch, with a waveform that looks like a sudden reversal of current flow. Regulation of the output is achieved by adjusting the on/off duty cycle of the primary-side switch; see References 1 through 5 for some additional insight.

Inside the IC

The IC contains 800-V startup circuitry that cuts the LED turn-on time to under an unnoticeable 250 ms. The high-voltage input-sensing circuitry and a maximum-power-control (MPC) engine also are integrated to ensure consistent power output as the line voltage fluctuates, a reality that designers must anticipate and overcome. This lets designers choose smaller and lower-cost external passive components to handle worst-case line conditions. Primary-sensing regulation without isolated feedback further reduces the bill of materials (BOM) and enhances reliability.

Among the patented innovations embodied in this IC is ST’s input-current shaping algorithm, which lowers total harmonic distortion (THD) and maximizes the power factor. Also, the HVLED101 is the first high power-factor flyback controller to implement the company’s new “valley-locking” technique to minimize audible noise (which can be an annoyance to users), improve regulation, and reduce distortion.

At steady state in quasi-resonant operation, this valley locking fixes the number of valleys skipped until it detects a significant change in output power or input voltage. Together, current shaping and valley locking enhance the power factor and THD, even at low and medium loads. Flyback converters controlled with the HVLED101 can achieve 5% THD at full load and 10% at one-third load to meet leading ecodesign codes.

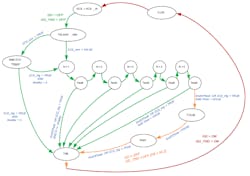

The sophistication of a device such as this controller is demonstrated by the complexity of the state diagram for the zero-current-detection (ZCD) mechanism (Fig. 2). Designers can program the delay time after zero-crossing detection in pure quasi-resonant operation using an external resistor.

By ensuring gate turn-on at the lowest point of the valley, the HVLED101 minimizes energy losses and EMI. Overall, the HVLED101 enables converters to achieve maximum efficiency above 90% and no-load power below 100 mW.

No controller can be considered “complete” without a set of protection features. The HVLED101 includes all necessary protection including overcurrent protection, input overvoltage protection, and brownout protection. There’s also a smart auto-reload timer (ART) that enables latch-free operation of all protection mechanisms to ensure high reliability and a superior consumer experience.

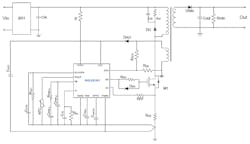

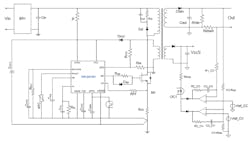

The HVLED101 supports both primary-side regulation (PSR; not to be confused with power-supply rejection) (Fig. 3) and secondary-side regulation (SSR; not to be confused with solid-state relays, of course) (Fig. 4).

Topology Debate

Which is the better topology? As with most such engineering questions, the answer is simple: it depends. Among the many decision factors are tightness of regulation, cost, component count, and isolation requirements (References 6 through 10 provide a variety of perspectives between the two, while References 11 and 12 have some detailed design guidance, including the critical transformer design).

Of course, when it comes to almost any circuit and especially one dealing with the ac line, dc, and fast switching, a reference-design schematic and BOM are useful necessities while an actual PCB is even better. Addressing this issue, ST offers two evaluation boards for the HVLED101 (Fig. 5): the EVLHV101PSR50W, a 90- to 265-V ac, 60-V/0.8-A/50-W isolated flyback converter with primary-side regulation, and the similar EVLHV101SSR50W, also a 50-W converter but with secondary-side regulation, both priced at $141 and supported by 14-page comprehensive data briefs.

The HVLED101 is in production now, housed in a narrow form-factor SO-14N package and priced from $0.99 for orders of 1,000 pieces.

References

1. Sunpower Electronics, “Flyback Converter”

2. ScienceDirect, “Flyback Converter”

3. Ronald Dekker, “Flyback Converters for Dummies”

4. Elprocus, “What is a Flyback Converter: Design & Its Working”

5. Circuit Cellar, “Flyback Converters”

6. Analog Devices, “Primary-Side Sensing Takes Complexity out of Isolated Flyback Converter Design”

7. Infineon Technologies AG, “Advantages of Secondary Side Control over Primary Side Control in Flyback Converter Solutions – KBA227974

Differences between PSR and SSR in bias power-supply design”

9. Fairchild/Onsemi, “Design Guideline for Primary Side Regulated (PSR) Flyback Converter Using FAN103 and FSEZ13X7”

10. Monolithic Power Systems, Inc., “Primary-Side vs. Secondary-Side Regulation”

11. Electronic Design, “Designing a Discontinuous-Conduction-Mode Flyback Transformer”

12. Electronic Design, “Take a Flier on the Flyback for Your High-Voltage Circuit Design”