Download this article in PDF format.

Most embedded systems use more than one power rail and many use four or more, making power-rail test and verification a time-consuming task. As the number of power rails goes past four, using a 4-channel oscilloscope to verify timing in an embedded application can turn into a rather slow process. To the rescue comes the more efficient 8-channel oscilloscope.

It turns out that evaluating power-on and power-off sequences is one of the most common reasons engineers give for wanting more than four channels. In this article, we’ll briefly cover using a 4-channel scope for this purpose, and then we’ll show some examples that take advantage of an 8-channel scope.

Why the Increase in Power Rails?

A single IC, such as an FPGA, DSP, or microcontroller, can require several power rails that may have specific timing requirements. For example, a chip manufacturer may recommend that the core voltage supply stabilize before applying the I/O supply voltage. Or a manufacturer may require that supplies come up within a specified time relative to each other to avoid prolonged voltage differences on various supply pins. The power-on sequence between processors and external memory can also be critical.

Chip manufacturers may specify that particular supplies must come up monotonically to avoid multiple power-on resets. This can be challenging since inrush currents can place high transient demands on point-of-load regulators. In this case, the shape of power-rail startup is as important as the timing sequence.

Combine the various chip supply requirements, bulk supplies, reference supplies, and multiple point-of-load regulators for other ICs in a design, and the design can reach up to seven or eight power rails in a hurry. However, the hurry stops when it comes time to testing and verifying all of these rails. It must be done carefully and methodically for each rail to ensure a successful design.

Traditional 4-Channel Oscilloscope Approaches

One approach when using a 4-channel oscilloscope is to analyze the power system in blocks, using multiple acquisitions to check the timing, block by block. To compare between blocks, one of the rails or a power-good/fail signal can be used as a trigger and multiple captures are able to be taken, determining the startup and shutdown timing relative to the reference signal.

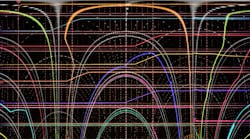

Since acquisitions are taken over multiple power cycles, variations in the relative timing of supplies will be difficult to characterize. However, the range of variation of each supply, from cycle-to-cycle, can be determined by measuring over multiple power cycles using infinite persistence on the oscilloscope.

Another common approach is to “cascade” multiple scopes. This is usually done by triggering the scopes on one of the power supplies, or on a common power-good or fail signal.

Both of these approaches are time-consuming and require that designers:

- Must carefully deal with synchronization and time uncertainty.

- Understand that aggregating data to develop a system timing diagram is possible, but time-consuming.

- Understand that complexity increases with the number of power rails to be observed.

- Make sure that setups are perfectly consistent.

- Use one measurement channel to provide synchronization.

Using an MSO to Extend Channel Count

A mixed-signal oscilloscope (MSO) can provide additional channels for power-supply sequencing. For this to work, the MSO must have suitable voltage range on the digital inputs and independently adjustable thresholds.

Designers looking for an MSO should look for 16 digital inputs with independent thresholds for each channel, as well as a ±30-V p-p dynamic range up to 200 MHz. This would be suitable for most of the voltage levels typically found. Note that this approach works well if the objective is strictly to measure timing relationships, but it doesn’t allow for measurement of rise/fall times or the shape (monotonicity) of the power-on/off.

8-Channel Scopes Speed the Process

Using an oscilloscope with eight analog channels cuts the time and hassle significantly, versus any of the methods covered so far. With an 8-channel oscilloscope, power supplies with up to eight power rails can be characterized using analog probes. To measure turn-on and turn-off timing relationships on power supplies with more than eight power rails, an MSO with digital signal inputs and independently adjustable thresholds can also be used.

Let’s look at some typical power-sequencing measurement applications.

Turn-On Delay with Remote On/Off

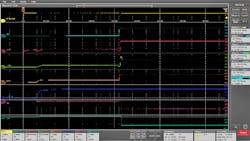

Figure 1 shows a switching power supply under test that produces a high-current, regulated 12-V dc output. This power supply is remotely controlled with a switch on the front panel of the instrument. Shortly after the switch is pressed, the +5-V standby voltage is turned on, enabling the switching converter to start. After the +12-V output is in regulation, the Power Good (PW OK) signal goes high to indicate to the load that the supply is reliable.

1. This screenshot shows measurement of an ac-dc switching power-supply turn-on after the front-panel switch was pressed.

The +5-V standby voltage signal provides a simple rising-edge trigger for the acquisition of the relevant signals. Automatic measurements verify that the delay to the output voltage turn-on is <100 ms, and the delay from output-voltage turn-on to PW OK is in the specification range of 100-500 ms.

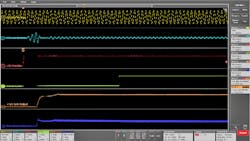

Turn-Off Delay with Remote On/Off

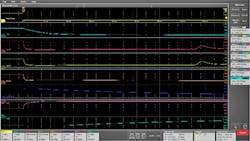

After the power supply’s main switch is turned off, the switching converter is turned off and the output voltage decreases. The power supply is specified to remain in regulation for at least 20 ms after the switch is pressed. Most importantly, the PW OK signal is specified to fall 5-7 ms before the +12-V output voltage falls out of regulation, allowing the load time to react and shut down cleanly.

2. A waveform cursor measurement can be used to verify that the PW OK pre-warning signal is operating as specified.

As shown in Figure 2, the PW OK signal provides a falling-edge trigger for the acquisition of the relevant signals. The waveform cursor measurement verifies that the PW OK pre-warning signal is operating as specified.

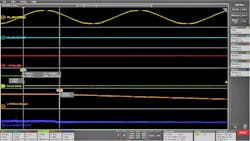

Verify Timing Over Multiple Power Cycles

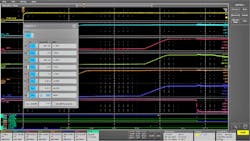

To verify that the power-supply turn-on timing remains within specifications over multiple power cycles, infinite persistence can be used to display the signal timing variations and statistics displays of automated timing measurements to quantify the variations. Figure 3 shows that the 50% point of the +5-V standby voltage serves as the timing reference. The turn-on sequence is repeated 10 times and the timing variations over the 10 turn-on cycles are within a little over 1%.

3. Repetitive turn-on timing measurements can be accomplished using infinite persistence and measurement statistics.

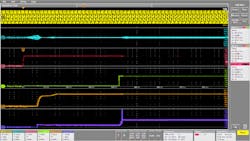

Point-of-Load Regulated Power-Supply Timing

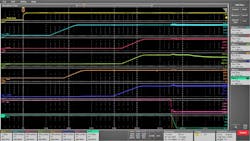

Figure 4 presents a screen capture of the turn-on timing of seven point-of-load supplies in a system board during power-up. The input power supplies to the circuit board are the +5-V standby and bulk +12-V dc supply from the previous example.

4. This measurement shows turn-on timing of seven regulated power supplies.

The automated turn-on delay measurements in this test are made between the automatically calculated 50% points of each of the waveforms, meaning that each measurement has a different configuration with a different set of measurement thresholds. The first measurement shows the delay from the +5-V standby signal to the bulk +12-V supply, and the second measurement is the delay to the main +5-V supply. The remaining measurements are the sequence of critical delays from the main +5-V supply.

Turn-Off Timing of Regulated Power Supplies

The automated turn-off delay measurements in this test are made between the points of each of the waveforms that are 5% below their nominal value. Unlike the previous percentage-based measurement thresholds, each measurement has an absolute voltage threshold. As the power supply shuts down, the Power Good signal falls. As seen in Figure 5, some of the supplies are more heavily loaded and turn off more quickly than others.

5. Some of the supplies are more heavily loaded and turn off more quickly than others, as visible here.

Turn-On Timing of More Than Eight Rails

Automated timing-delay measurements are simply based on the times at which the signals cross their respective threshold voltages. Since each automated measurement configuration can include a unique threshold value (typically 50% of the signal amplitude) and each digital channel can have a unique threshold value (also typically set to 50% of the power-supply voltage), MSOs can make power-supply timing-delay measurements (Fig. 6) up to the number of available digital inputs. Depending on the MSO model, the number of channels can range from 8 to 64.

6. This shows the use of digital channels when the turn-on timing of more than eight regulated power supplies needs to be verified.

Power-Supply Rise-Time Measurements

In addition to the power-supply sequencing, the rise times of power supplies must be controlled to meet the specifications of some critical components in a system. Automated rise- and fall-time measurements are also made based on voltage reference points that are, by default, automatically calculated to be 10% and 90% of the signal amplitude of each channel. In a simple example (Fig. 7), the rise times of the positive supplies and the fall times of the negative supplies are shown in the results boxes on the right side of the display.

7. Rise- and fall-time measurements are shown in the results boxes on the right side of the display.