Members can download this article in PDF format.

Slowing global warming by reducing vehicle CO2 emissions is, for many, a compelling selling point for electric vehicles (EVs). In all, according to the U.S. Environmental Protection Agency (EPA), transportation was responsible for 27% of greenhouse-gas emissions in 2020, which primarily come from burning fossil fuel for our cars, trucks, ships, trains, and planes.

As a result, while taxes may be one of the few certainties in life, here’s another: In the transition to EVs, the auto industry plans to invest more than $330 billion through 2025 to advance vehicle electrification, according to the IHS Markit EV charging infrastructure forecast. These EVs will need charging stations that are fast, efficient, and powerful.

Consequently, and also according to IHS Markit, the global deployment of EV charging stations will increase at a 31% CAGR to more than 66 million units by 2030. An estimated 20 million public EV charging stations will connect to the grid, with residential charging stations expected to scale up significantly.

Sponsored Resources:

- Building a fast, flexible EV charging network

- Misconceptions about EV charging

- Top 3 design considerations for EV charging

Yet despite the growing popularity of EVs, mass adoption still faces major barriers. This is mainly due to consumer worries over issues such as the limited range of EVs, long charging times, the availability of charging stations, and inaccurate estimation of available range.

The Need for Efficient EVSE

Since it’s less expensive and better for the environment to save energy in power supplies than to generate more electricity in fossil-fuel power plants, efficiency has become a top priority in all new design activity involving EV charging.

To deliver energy from the electric grid to a vehicle’s battery, a charging station, sometimes referred to as electric-vehicle supply equipment (EVSE), is needed. It must be quick, affordable, and safe while providing a flexible infrastructure to generate, store, transmit, and distribute the necessary power.

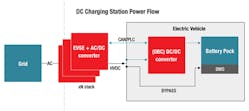

Designing an EV charging station includes unique challenges. Not only must EVSE incorporate communications, safety, and security, it needs to provide an upgrade path to accommodate the future of grid integration (Fig. 1). Key parameters for dc chargers include energy density and energy efficiency, both of which are enabled by high switching frequencies. Such frequencies minimize the size of a charger’s magnetics and lessen losses, allowing for the use of smaller heatsinks.

Grid Support

Power modules are a critical element in this scenario. Market research firm Yole Group predicts the power-module market for EVs will reach US$3.59 billion by 2026. Found on the input side of an EV charging station, this block converts the incoming ac voltage into a fixed dc voltage. The voltage serves as input to the dc-dc power stage, which processes power and interfaces directly with the battery on the electric vehicle.

Bidirectionality (two-way charging) is a key feature for supporting vehicle-to-grid (V2G) applications. In this case, a car battery can provide load balancing by feeding power back to the grid at times of peak demand (Fig. 2).

TI’s energy-metering technology can measure power-distribution flows between EVs, consumers’ batteries, and the grid. And TI’s embedded processing technology, like the TI C2000 real-time microcontroller, works with isolated gate drivers and fully integrated gallium-nitride (GaN) power devices to boost charging efficiency.

Misconceptions

Even though it’s evolving quickly from novelty into necessity, some prominent misconceptions abound regarding EV charging. For example, there’s the mistaken belief that all EV charging stations use the same charging technology. Uh-uh. The fact is mainly two types of charging systems are available: ac and dc, and three levels (L1, L2, and L3).

Levels 1 and 2, as established by Society of Automotive Engineers (SAE), are ac chargers that power the EV battery through the vehicle’s on-board charger, while a dc charger directly charges the vehicle’s battery. Level 3 uses a power-conversion stage built within an external charger and bypasses the EV’s onboard charger.

An L1 ac implementation operates at 120 or 230 V ac (single phase) and can charge a 24-kWh battery in approximately 17 hours. An L2 implementation operates at 208 to 240 V ac (single/split phase) and will charge the same battery in approximately eight hours.

Over time, the capacity of dc fast-charging stations has increased significantly. Where the standard was once 150 kW, we’re now looking at capacities of 350 kW and beyond—and the improvements will continue. As a result, EVs will charge faster. The dc fast chargers typically charge batteries to 80% state of charge (SOC) in under 30 minutes, which will help ensure chargers aren’t the bottleneck for getting more EVs on the road.

Then there’s the misconception that connectivity has no role in EV charging. Connectivity enables access control from the cloud. A two-way vehicle communication module might include interfaces like a controller area network (CAN), RS-485, or Ethernet to communicate with the EV as well as to the charging-station network.

The Open Charge Point Protocol (OCPP) is the standard of communication defined between charging stations and the charging-station network that manages data exchange. Connectivity via this protocol is achievable with Ethernet, cellular, Wi-Fi, or sub-1-GHz signals. TI’s Sitara processors with Linux software supports OCPP as well as the International Organization for Standardization (ISO) 15118 V2G communication interface for information exchange between EVs, charging stations and utilities.

Powering the Transition to Electrification

It’s well-known that semiconductor technology separates the haves from the have-nots in the effort to make EV charging more convenient, affordable, and sustainable. For EV charger proliferation to occur at the predicted levels, technological improvements in electronic components are needed to make it possible to create more flexible and energy-efficient devices.

On that front, TI’s integrated circuits and reference designs help create smarter and more efficient dc fast-charging stations for EVs. Whether it’s a power-factor-correction (PFC) stage, dc-dc power-stage design, or the central control system, TI offers the ingredients needed to design an efficient, flexible charging station. In short, TI is ready to offer everything you need to build your next-generation dc EV fast-charging station.

Sponsored Resources: