Head-up displays (HUDs) were initially developed for defense aviation many decades ago. Today, the technology is quickly evolving in automotive applications to give drivers information such as navigational data on a transparent screen right in the driver’s line of sight. A key element of data displayed by HUDs is that they are presented in a way that does not distract drivers. A market report from BCC Research states that the market for HUD components is expected to grow to $8 billion by 2022 from $2.7 billion this year. The following two options, which are being used by automotive original-equipment-manufacturer (OEM) developers, rely on cutting-edge technologies to improve the driver’s experience.

Shown is a head-up display feature in the 2017 Lincoln Continental. (Courtesy of Texas Instruments)

Digital Light Processing (DLP)

DLP is a display device technology based on optical microelectromechanical systems (MEMS). At its heart is a digital micromirror device. For example, Texas Instruments has taken the technology behind its DLP Cinema projection product and qualified it for automotive applications. The chipset consists of highly reflective, digitally switchable, micrometer-sized mirrors (micromirrors). The micromirror array consists of 608 micromirror columns by 684 micromirror rows in a diamond pixel configuration. Each individual micromirror is positioned over a corresponding CMOS memory cell. The angular position of a specific micromirror is determined by the binary state (logic 0 or 1) of the corresponding CMOS memory cell contents after the mirror clocking pulse is applied

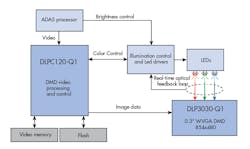

The company’s chipset (DLP3000-Q1) targets a wide field of view and augmented-reality HUD applications with a field of view reaching 12 × 5 deg. The chipset family consists of a DLP 0.3-in. wide video graphics array (WVGA) digital micromirror device (DMD) and DLPC120 controller. The controller is responsible for accepting the video input and formatting the data to display on the DMD while simultaneously controlling RGB light-emitting diodes (LEDs) in order to create a real-time image. The DLP also controls the power-up and power-down events of the DMD according to external system control or temperature input from the DMD.

With this chipset, automakers and Tier 1 suppliers can reportedly design HUDs with Virtual Image distances to 20 meters. (Courtesy of Texas Instruments)

Laser-Scanned MEMS Projection Display

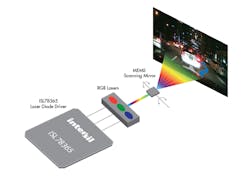

In a laser-scanned MEMS projector, each pixel is pulsed very rapidly to create the full high-definition resolution. Because the laser beam is always in focus, the image can be projected into the windshield without requiring refocusing optics. This greatly reduces the overall optical system complexity and size, eliminating costly optical components and assembly.

A laser-scanned MEMS HUD consumes electrical power when there are relevant pixels to be projected. With the typical navigation and instrumentation information, most of the electrical energy is consumed when there is a need to put a pixel onto the display. This dramatically reduces the electrical requirement, resulting in a lower thermal profile and thus smaller thermal dissipation requirements.

Intersil’s ISL78365 is an AEC-Q100 Grade-1 qualified laser diode driver that pulses four high-intensity lasers up to 750 mA for projecting full HD color video onto the windshield. The chip supports a wide variety of color laser-diode configurations, allowing system designers to achieve the desired brightness, contrast, and rich color image. To meet the thermal requirements, the device offers three power-saving modes for high efficiency and low power losses.

Pictured is an example of a laser-scanned MEMS projection system for an automotive head-up display. (Courtesy of Intersil)

These two technologies are among the many options that automotive OEM developers are considering. Several factors are considered when deciding which one to use, like the amount of content on the display, brightness, dimming range, supplied power, size,and—last, but not least—the cost of the solution. As prices for HUDs fall, we will start to see a migration of this technology from luxury cars to more affordable car options.

About the Author

Maria Guerra

Power/Analog Editor

Maria Guerra is the Power/Analog Editor for Electronic Design. She is an Electrical Engineer with an MSEE from NYU Tandon School of Engineering. She has a very solid engineering background and extensive experience with technical documentation and writing. Before joining Electronic Design, she was an Electrical Engineer for Kellogg, Brown & Root Ltd (London. U.K.). During her years in the Oil and Gas Industry she was involved in a range of projects for both offshore and onshore designs. Her technical and soft skills bring a practical, hands-on approach to the Electronic Design team.