Members can download this article in PDF format.

In this design idea, you will learn how to interface two PIC microcontrollers using a wireless 433-MHz RF transmitter/receiver pair to control up to six relays and monitor two analog signals. The design will find multiple applications intended for smart-home systems. The RF modules (PT2262) used in this setup are available from Digi-Key (P/N: 1597-1223-ND).

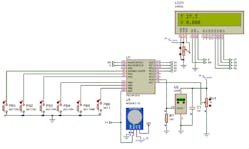

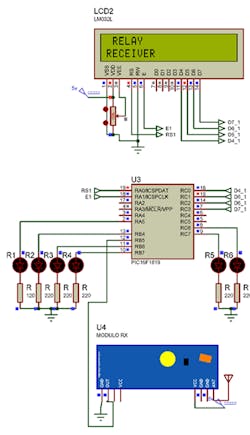

Figure 1 shows the transmitter based on the microcontroller PIC16F1619. Pushbuttons PB1 thru PB4 are enabled to control four relays in the receiver module in Figure 2.Pushbuttons PB5 and PB6 are used to set the voltage thresholds for the temperature sensor applied on input RC6, and the potentiometer connected on RC7 in the microcontroller. These two readings control Relays 5 and 6, respectively, in the receiver module. This feature can be used to operate as a thermostat in A/C systems.

PB5 and PB6 are configured to set up temperature and voltage, respectively. Temperature can be set in intervals of 1°C. The second signal that can be measured is voltage. It can be set in intervals of 10 mV, setting the maximum voltage to 4.99 V.

When setting the values of temperature and voltage, an interval is created, in which their state doesn’t change. This is called hysteresis. When the temperature increases ±1°C, the voltage changes with a resolution of 10 mV. If the voltage or temperature is within two intervals, it will remain in the last active state, either On or Off. This is used to avoid damaging the connected relays.

Listings 1 and 2 below show the code for the transmitter and receiver modules, respectively. The transmitter module displays the actual temperature detected by the LM34 sensor, and the voltage coming from the trim potentiometer. The receiver module displays the status of each relay.

This circuit uses the EUSART (Enhanced Universal Synchronous Asynchronous Receiver Transmitter) modules embedded in two PIC microcontrollers 16F1619 and 16F1614. The communication is full-duplex between both devices (Rx and Tx).

To establish communication, it’s necessary to have a starting bit for a period of time to alert the receptor that a data package is about to be transmitted. This allows the receiver clock to start synchronization with a 0 bit. Then each bit is sent individually, starting with the LSB bit through the MSB bit. Each bit has the same period. Once all bits are transmitted, it has to wait for the high-logic Stop bit to indicate end of transmission.1

Figures 3 and 4 show the actual assembled circuits in two printed circuit boards.

Reference

1. Jimenez, Ricardo, and Alvarez, Gabriel L. “Microcontroller Sends Voltage and Frequency via Low-Cost Modules,” Aug. 12, 2020, www.electronicdesign.com.

Listing 1: Code for the Transmitter PIC16F1619

'* Name : Wireless RF Transmitter module code

'* Date : 6/10/22 *

'* Version : 1.0 PIC16F1619 PBP3 compiler melabs.com

'* Notes : Transmitter 4 relays;

#CONFIG

__config _CONFIG1, _FOSC_INTOSC & _PWRTE_ON & _MCLRE_OFF & _CP_OFF & _BOREN_ON & _CLKOUTEN_OFF

__config _CONFIG2, _WRT_OFF & _PPS1WAY_OFF & _ZCD_OFF & _PLLEN_OFF & _STVREN_ON & _BORV_LO & _LVP_OFF

__config _CONFIG3, _WDTCPS_WDTCPS4 & _WDTE_ON & _WDTCWS_WDTCWS100 & _WDTCCS_LFINTOSC

#ENDCONFIG

;CONFIGURATION OF THE INTERNAL CLOCK

OSCCON = %01101010; $6A, INTERN CLOCK AT 4MHZ

OSCSTAT = %00011111; $1F, INTERNAL CLOCK ENABLE

OSCTUNE = 0;INTERNAL OSC WORKS AT THE CALIBRATED FREQUENCY

; PINS CONFIGURATION

;--PORTA--

TRISA = %00111100; RA3:RA4:RA5 AS INPUT

ANSELA = %00000100; ALL PINS ARE DIGITAL

OPTION_REG.7=0; PULL-UPS ENABLED

WPUA = %00111000; RA2:RA5 PULL-UPS enabled

;--PORTB--

TRISB = %01110000; RB4:RA5:RB6 AS INPUT

ANSELB = 0; ALL PINS ARE DIGITAL

WPUB = %01110000; RB4:RA5:RB6 ENABLED PULL UPS

;--PORTC--

TRISC = %11000000; RA6:RA7 AS INPUTs

ANSELC = %11000000; RA6:RA7 ARE ANALOG

WPUC = 0; PULL UPS DISABLED

;---

INTCON = %11000000; ENABLE ALL INTERRUPTs

;ADC CONFIGURATION

ADCON0 = %00001101; ADC ENABLED

ADCON1 = %10000000; RIGHT JUSTIFIED

;PIE1 = %01000000; ENABLED ADC INTERRUPT

;--LCD CONFIGURATION ----------------------

DEFINE LCD_DREG PORTC ' THE DATA CHANNEL IS THE PORTC

DEFINE LCD_DBIT 0 ' PORTC.0 IS THE LSB

DEFINE LCD_RSREG PORTA ' RS IS CONNECTED IN PORTA.0

DEFINE LCD_RSBIT 0

DEFINE LCD_EREG PORTA ' E IS CONNECTEC IN PORTA.1

DEFINE LCD_EBIT 1

DEFINE LCD_BITS 4 ' 4 LINES OF DATA

DEFINE LCD_LINES 2 ' THE DISPLAY IS OF 2 LINES

DEFINE LCD_COMMANDUS 1500 ' 1500uS OF COMMAND TIME

DEFINE LCD_DATAUS 44 '44uS TIME OF DATA

;-----------------------------------------------------

;SERIAL PORT CONFIG

TX1STA = %00100000; $20, ENABLE TRANSMISSION, 8 BITS, LOW VELOCITY

BAUD1CON = %00000000; NO INVERTER, DETECTION OF FALLING EDGE

SPBRGL = 25; CALCULATED at 2400 BPS

RC1STA.7 = 1; ENABLE SERIAL PORT

RB7PPS = %10010; ACTIVATING PPS MODULE

;---------------------------------------------------------

;TIMER 1 CONFIG

T1CON = %11000101; TIMER 1 ENABLED, LFINTOSC, 1:8 PREESCALE

;-----------------------------

;variables

ADC VAR WORD

REMAINDER VAR WORD

RELE VAR BYTE

VIN VAR WORD

VR VAR WORD

ES1 VAR BIT

ES11 VAR BIT

ES2 VAR BIT

ES21 VAR BIT

TR VAR WORD

CH VAR BYTE

VP VAR WORD

TP VAR WORD

DIR VAR WORD;

DAT VAR WORD

T VAR BYTE[4]

VD VAR BYTE[4]

X VAR BYTE

R VAR BYTE;

STATE VAR WORD;

Y VAR BYTE

TIME VAR BYTE

TMR VAR WORD

;ALIAS

PB1 VAR PORTA.3;

PB2 VAR PORTA.4;

PB3 VAR PORTA.5;

PB4 VAR PORTB.4;

PB5 VAR PORTB.5;

PB6 VAR PORTB.6;

;---INITIALIZATION--

RELE = 0;

TR = 0;

;VP = 9999;

;TP = 9999;

VR = 0;

ES1 = 0

ES2 = 0

ES11 = 1;

ES21 = 1;

FOR X = 0 TO 3

VD[X] = 0

T[X]=0

NEXT X

TIME = 250

;------

READCODE $1FF5,STATE

IF STATE = 0 THEN

READCODE $1FF6,TP;

READCODE $1FF7,VP;

ELSE

VP = 9999;

TP= 999;

DIR = $1FF5;

DAT = 5;

GOSUB ERASE

GOSUB SAVE

ENDIF

;------------

LCDOUT $FE, $80, "WIRELESS"

LCDOUT $FE,$C0, "CONTROLLER "

PAUSE 1000;

;LCDOUT $FE, $80, "your name “

;LCDOUT $FE,$C0, "your session "

;PAUSE 2000;

MAIN:

;R = RELE.

R.0 = PB1

R.1 = PB2

R.2 = PB3

R.3 = PB4

IF pb1 = 0 THEN; WHEN BUTTONS IS PRESSED

PAUSE TIME

RELE.0= 1; INVERT STATE

GOSUB SEND

RELE.0 = 0;

ENDIF

IF PB2 = 0 THEN

PAUSE TIME

RELE.1= 1; INVERT STATE

GOSUB SEND

RELE.1 = 0;

ENDIF

IF PB3 = 0 THEN

PAUSE TIME

RELE.2= 1; INVERT STATE

GOSUB SEND

RELE.2 = 0

ENDIF

IF PB4 = 0 THEN

PAUSE TIME

RELE.3= 1; INVERT STATE

GOSUB SEND

RELE.3= 0;

ENDIF

IF PB5 = 0 THEN GOSUB SET_TEMP; VOLTAGE SETPOINT

IF PB6 = 0 THEN GOSUB SET_V; TEMPERATURE SETPOINT

;GOSUB ADC_READ;

;-*---

CH = 2; AN9 VOLTMETER, TEMP

GOSUB ADC_READ

GOSUB D_V;

VR = VIN

;--------

CH = 8; AN8 VOLTMETER

GOSUB ADC_READ

GOSUB D_T

TR = VIN;

PAUSE 200

;-------

IF TR > TP THEN; WHEN READ TEMPERATURE IS HIGER THAN SET POINT

ES1 = 0;

RELE.4 = 1

ELSE

ES1 = 1;

RELE.4 = 0;

ENDIF

;----

IF VR>VP THEN; WHEN READ VOLTAGE IS HIGHER THAN SET POINT

RELE.5 = 1

ES2 = 0;

ELSE

RELE.5 = 0

ES2 = 1

ENDIF

;----

IF ES11 <> ES1 THEN; IF THE STATE IS DIFFERENT

GOSUB SEND;

ES11 = ~ES11;

ENDIF

IF ES21 <> ES2 THEN; IF THE STATE IS DIFFERENT

GOSUB SEND;

ES21 = ~ES21;

ENDIF

;---- display temperature and voltage ------

LCDOUT $FE,$80,"T= ",DEC T[2], DEC T[1],".",DEC T[0]," 'C"

pause 200;

LCDOUT $FE,$C0,"V= ",DEC VD[3],".",DEC VD[2],DEC VD[1],DEC VD[0]," V"

pause 500;

GOTO MAIN

;----------------

SET_TEMP:

PAUSE TIME;

TMR1L = 0;

TMR1H = 0;

FOR Y = 0 TO 1

TMR1L = 0;

TMR1H = 0;

TEMP_STAY:

if PB5 = 0 THEN

TP = TP+5; INCREMENT TEMPERATURE SET POINT BY 0.1 DEGREE

PAUSE 150;

Y = 0;

IF TP > 999 THEN TP=0; IS THE SET POINT IS HIGHER THAN 99.9?

TMR1L = 0;

TMR1H = 0;

ENDIF

VIN = TP;

GOSUB D_T

TMR.BYTE0 = TMR1L;

TMR.BYTE1 = TMR1H;

LCDOUT $FE,$80,"SET TEMP"

lcdout $fe,$c0,DEC t[2],dec t[1],".",dec t[0]," "

IF TMR < 31000 THEN GOTO TEMP_STAY; IF NOT ELAPSED TIME

NEXT Y

gosub SECUENCE

RETURN;

;----------------

SET_V:

PAUSE TIME

FOR Y = 0 TO 1

TMR1L = 0;

TMR1H = 0;

V_STAY:

if PB6 = 0 THEN

VP = VP + 50; INCREMENT VOLTAGE trip point BY 50 mV

PAUSE 100;

Y = 0;

IF VP >4900 THEN VP = 0; IF trip point IS HIGHER THAN 4.9V

TMR1L = 0;

TMR1H = 0;

ENDIF

VIN = VP

GOSUB D_V;

LCDOUT $FE,$80,"SET VOLTAGE"

lcdout $fe,$c0,DEC VD[3],".",dec VD[2],dec VD[1],DEC VD[0]," "

TMR.BYTE0 = TMR1L;

TMR.BYTE1 = TMR1H;

IF TMR< 31000 THEN GOTO V_STAY; IF NOT ELAPSED THE TIME

NEXT Y

GOSUB SECUENCE

RETURN

;----------------

ADC_READ:

CH = CH<<2;

ADCON0 = CH^%10000001; BITWISE XNOR

PAUSE 1

ADCON0.1 = 1;

;PAUSE 1; ENABLE ADC MODULE IN PIC

HERE1: IF ADCON0.1 = 1 THEN HERE1; wait for conversion bit

ADCON0.0 = 0;

ADC.BYTE0 = ADRESL; SAVE LOWER REGISTER ADC IN VARIABLE VIN

ADC.BYTE1 = ADRESH; SAVE HIGHER REGISTER ADC IN VARIABLE VIN

REMAINDER = ADC*4887; MULTIPLYING BY RESLSB = 4.8887

VIN = div32 1000; PERFORM 16-BIT DIVISION

return

;-------

D_T:

FOR X = 0 TO 3; OBTAIN THE DIGITS

T[X]= VIN DIG X

NEXT X

RETURN

;---

D_V:

FOR X = 0 TO 3; OBTAIN THE DIGITS

VD[X]= VIN DIG X

NEXT X

RETURN

;----

SEND:

for x = 0 to 2

HSEROUT ["R",DEC X,RELE] ; SEND DATA IN SERIAL PORT

next x

RETURN

;-------

UNLOCK: ; UNLOCK SEQUENCE

ASM

BANKSEL PMCON2

MOVLW 0x55

MOVWF PMCON2 & 0x7F

MOVLW 0xAA

MOVWF PMCON2 & 0x7F

BSF PMCON1 & 0x7F,1 ; set WR bit

NOP

NOP

ENDASM

RETURN

;----------

ERASE: ;required sequence

PMCON1.4 = 1;

PMCON1.2 = 1;

GOSUB UNLOCK;

PMCON1.2=0;

PMCON1.4=0;

RETURN

;

SECUENCE: ;data save sequence

GOSUB ERASE

DIR = $1FF5

DAT = 0;

GOSUB SAVE

DIR =$1FF6;

DAT = TP;

GOSUB SAVE;

DIR =$1FF7

DAT = VP

GOSUB SAVE

RETURN

SAVE: ;instruccion set

PMADRL = DIR.BYTE0;

PMADRH = DIR.BYTE1;

PMDATL= DAT.BYTE0;

PMDATH= DAT.BYTE1;

PMCON1.6 = 0;

PMCON1.5 = 0;

PMCON1.4 = 0;

PMCON1.2 = 1;

PMCON1.1 = 1;

PMCON1.0 = 0;

GOSUB UNLOCK;

STAY:IF (PMCON1.1 = 1) AND (PMCON1.3 = 1)THEN STAY;

IF PMCON1.3 = 1 THEN save;

PMCON1.6=0;

PMCON1.5=0;

PMCON1.1=0;

PMCON1.2=0;

RETURN;

Listing 2: Code for the Receiver Unit Using a PIC16F1619

'* Name :

'* : pic16f1619 pbp3 compiler from melabs.com

'* Date : 6/10/22 *

'* Version : 1.0 *

'* Notes : Receiver for 6 relays;

#CONFIG

__config _CONFIG1, _FOSC_INTOSC & _PWRTE_ON & _MCLRE_OFF & _CP_OFF & _BOREN_ON & _CLKOUTEN_OFF

__config _CONFIG2, _WRT_OFF & _PPS1WAY_OFF & _ZCD_OFF & _PLLEN_OFF & _STVREN_ON & _BORV_LO & _LVP_OFF

__config _CONFIG3, _WDTCPS_WDTCPS4 & _WDTE_ON & _WDTCWS_WDTCWS100 & _WDTCCS_LFINTOSC

#ENDCONFIG

; INTERNAL CLOCK configuration

OSCCON = %01101010; $6A, INTERN CLOCK AT 4MHZ

OSCSTAT = %00011111; $1F, INTERNAL CLOCK ENABLE

OSCTUNE = 0;INTERNAL OSC WORKS AT CALIBRATED FREQUENCY

; PINS CONFIGURATION

;--PORTA--

TRISA = 0; RA4 INPUT, all other are outputs

ANSELA = 0; RA4 ANALOG, all other are digital

OPTION_REG.7=0; pull-ups control

WPUA = 0; PULL-UPS Disabled

;--PORTB--

TRISB = %00100000;

ANSELB =

WPUB = 0; PULL UPS DISABLED

;--PORTC--

TRISC = 0; portc set to outputs

ANSELC = 0; digital port

WPUC = 0; PULL UPS Disabled

;---

PORTC = 0

PORTB = 0

PORTA = 0

PAUSE 1000;

;--LCD CONFIGURATION ----------------------

DEFINE LCD_DREG PORTC ;DATA CHANNEL IS PORTC

DEFINE LCD_DBIT 0 ' PORTC.0 IS THE LSB

DEFINE LCD_RSREG PORTA ' RS IS CONNECTED IN PORTA.0

DEFINE LCD_RSBIT 0

DEFINE LCD_EREG PORTA ' E IS CONNECTED IN PORTA.1

DEFINE LCD_EBIT 1

DEFINE LCD_BITS 4 ' 4 DATA lines

DEFINE LCD_LINES 2 ' DISPLAY IS 2 LINES

DEFINE LCD_COMMANDUS 1500 ' 1500uS COMMAND TIME

DEFINE LCD_DATAUS 44 '44uS DATA time

;------SETTING UP LCD------------------------------------------------

LCDOUT $FE,$28; $28 FUNCTION SET, 4 BITS

LCDOUT $FE,$10; $10 SHIFT DISPLAY

LCDOUT $FE,$0C; $0C DISPLAY ON

LCDOUT $FE,$06; $06 ENTRY MODE SET

;-------------------------------------------------------------------------------

;SERIAL PORT config

RC1STA = %10010000; ENABLED SERIAL PORT

BAUD1CON = %00000000; NO INV, FALLING EDGE detection

SPBRGL = 25; CALCULATED OF 2400 BPS

RXPPS = %01101

DEFINE HSER_CLROERR 1; CLEAR OVERRUN ERROR

;---------------------------------------------------------

LCDOUT $FE,$80," WIRELESS RELAY "

LCDOUT $FE,$C0," RECEIVER "

PAUSE 5000;

; VARIABLES------

RELE VAr byte;

B VAR BYTE;

ANT VAR BYTE;

STATE VAR BYTE

x var byte

;---ALIAS

RE1 VAR PORTA.5

RE2 VAR PORTB.4

RE3 VAR PORTB.6

RE4 VAR PORTB.7

RE5 VAR PORTC.6

RE6 VAR PORTC.7

;---------

STATE = 0;

;-----

MAIN:

HSERIN [WAIT("R2"),rele]

IF RELE.0 = 1 THEN RE1 = ~RE1

IF RELE.1 = 1 THEN RE2 = ~RE2

IF RELE.2 = 1 THEN RE3 = ~RE3

IF RELE.3 = 1 THEN RE4 = ~RE4

;RE1 = STATE.0

;RE2 = STATE.1

;RE3 = STATE.2

;RE4 = STATE.3

RE5 = RELE.4

RE6 = RELE.5

lcdout $fe,$80,"RELAYS "

lcdout $fe,$C0,"R= ",bin re6," ",bin re5," ",bin re4," ",bin re3," ",bin re2," ",bin re1;

pause 300;

GOTO MAIN

END