This video/article is part of Dostal's Design series in Ideas for Design and the TechXchange: Power Supply Design. You can also post a question.

Members can download this article in PDF format.

Nearly every electronic circuit today needs several different supply voltages. A suitable power-management architecture must be designed for the different required voltage rails. Typically, multiple voltage converters working according to the switching regulator principle are used. In this design approach, each of these switching regulators needs an inductor.

For an end-product, it’s often important to use as little PCB space as possible and that the associated costs be as low as possible. A popular way to accomplish those goals is by taking the integration route. Integrating the circuit into the silicon works well for switching regulators and linear regulators at low power.

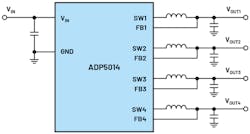

A large selection of combined, highly integrated switching regulator ICs, often also referred to as power-management integrated circuits (PMICs), is available. Figure 1 shows such a highly integrated dc-dc converter, the ADP5014.

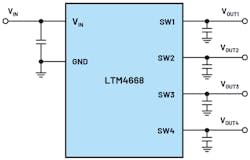

To reduce the package size of the circuit shown in Figure 1 even further, it’s possible to integrate the inductors into the package. This can be accomplished with an LTM4668, as shown in the solution in Figure 2. It has four channels and requires only a low number of external components because the usually rather large inductors are integrated into the package.

The LTM module family provides a high power density, has exceptional EMC behavior, and is extremely robust. However, it can be more costly compared to a solution with external components.

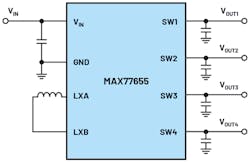

There’s a third solution similar to the concept shown in Figure 1. It’s composed of a single-inductor multiple-output (SIMO) converter. Here, one inductor is used as an energy-storage device, specifically as a current-storage device, and all channels share it.

Many different versions exist. The inductor can be charged with energy at one point in time and then the energy is discharged partially via the different channels. In another implementation, the inductor is charged and then completely discharged for one channel. Afterward, this empty energy-storage device is passed on to the next channel, where it’s charged and discharged again, and then to each subsequent channel until all channels have been supplied.

The power supply has different characteristics depending on the given implementation. In general, this concept works quite well with relatively low power. The sizing of the internal MOSFETs and the design of the single external inductor are optimized for low power.

The integrated switches in the MAX77655 that allow the single inductor to be used for all channels also enables the available voltage to be converted to a higher or lower voltage. The respective operating mode is made possible through the appropriate driving of the integrated MOSFETs.

With a SIMO converter as shown in Figure 3, multiple voltages can be generated efficiently with just one energy-storage inductor. This provides for a more compact power-supply architecture and can lower the costs.