Download this article in PDF format.

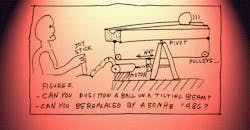

In 1995, Bob Pease wrote a great article about a ball-on-beam balancer (BOBB) he designed. Making a servo system that can keep a ball balanced on a beam is an interesting control challenge, similar to the inverted pendulum. Pease was inspired to create one because he was exasperated with Fuzzy Logic (Parts I, II, III, IV, V, VI). Now Pease was a famous analog engineer, but he wasn’t bothered by the fact that Fuzzy Logic was digital. Indeed, in Part I, he said, “...a well-designed digital controller can obviously operate as smoothly as you would like.” He also readily admitted that a Fuzzy Logic controller might be simpler and better suited to some nonlinear problems.

What bothered Pease were all of the wild claims that Fuzzy Logic was superior, combined with the assertion that you don’t even have to understand how the controller works. It was some kind of new-age fuzzy magic. Like digital power a decade later, a bunch of exaggerated claims were made by well-meaning software engineers who never had a control theory course in college. Pease wrote an article about the PID (proportional, integral, derivative) controller to help expose the engineering community to the beauties of modern linear control theory. There are videos of PID controllers running on an Arduino that make a serviceable BOBB.

Pease had become incensed at a paper from Texas Tech that showed a Fuzzy Logic BOBB, and even presented a prototype. So he set out to design a controller with pure analog. The one he came up with used six op amps. I am not sure what happened to it; it may be in an archive at Texas Instruments.

You can imagine my delight when Reginald Neale contacted me and said he had a video Pease sent him of the BOBB working at the Wescon show in San Francisco circa 1995. Check it out:

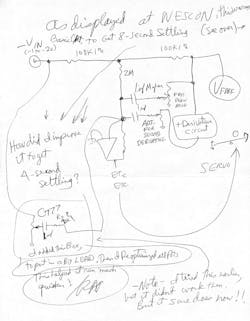

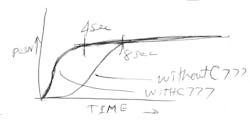

At 5:14, you can get a glimpse of Frank Goodenough, Electronic Design’s analog editor at the time: Pease was good friends with Goodenough and noted his passing in a poignant prefix to an April Fool’s article. Along with the video, Pease sent Neale a hand-drawn schematic explaining a speed-up circuit he added (Fig. 1). On the back was a crude graph Pease did to show the improvement in response time (Fig 2). In the accompanying letter Pease sent to Neale, he noted, “This indicates that my BOBB is fairly smooth and well-behaved, even with the new C777 [circuit].”

It was great to hear Pease’s voice again as he demonstrates the balance. There is a segment after the demo of Pease operating the balance by hand in his lab at National Semiconductor (now Texas Instruments). This was a wonderful aspect of Pease’s curiosity. He evaluated how a human would balance the ball, before he tried to design the control system for it. I have heard that German machinist apprentices are made to use a file before they can access the machine tools. It gives them a feel for the metal, so that they better understand what the machine is doing and its limitations.

1. Bob Pease's hand-drawn schematic of the ball-on-beam balancer demonstrated at Wescon.

Digital Doesn’t Dominate

As to Fuzzy Logic, it looks like it has run thought the hype cycle, and is now used where it makes sense by engineers who understand its benefits and limitations. This is much like the digital-power hype that happened 10 years after Fuzzy Logic. It’s not that digital-power control loops are invalid; it’s that their proponents made claims that they were always superior. Since then, I have seen many examples of both analog and digital power controllers.

Digital power is not always superior. I had a friend at a huge network company tell me how a vendor promised its digital-power controller would be superior. Problem was the layout had to allow the output capacitors to be many inches from the controller due to mechanical design issues. The digital controller could not handle this, whereas the existing analog controller worked fine. My friend noted that the only performance difference in digital control was the greater cost of the chips.

On the plus side were companies like iWatt (now Dialog Semiconductor) and CamSemi (now Power Integrations). They told me that many of their wall-wart IC parts used digital power, but they did not even mention it because digital power was so over-hyped. Some of the benefit came about because a flyback controller is a bit nonlinear, since it has to blank out the feedback until it is valid. Note that wall-warts are a high-volume product that would support a fine-line CMOS design effort.

2. On the back of the paper with the hand-drawn schematic in Fig. 1, Pease sketched out the improved response time of the BOBB.

Analog vs. Digital

The true difference came out when I talked to Abid Hussain, a marketing manager at Summit Microelectronics (now Qualcomm). He noted that the company’s parts were meant for mobile phones and portable battery-powered electronics. Digital control was used to manage the chip, but the actual servo loop was analog. This was due to the need for microwatt power budgets. A digital loop with its data sampling and fast computation would consume far too much power.

Pease also told me how sampled-data systems often have to consume much more power compared to an analog real-time system. The power savings inherent in analog real-time computation chips gave rise to companies like GTronix, which used analog to do noise cancellation and other tasks typically handled by a DSP (digital signal processor).

Shortly after, Paul Greenland, then at National Semi and now at Advanced Energy, explained the realities of digital-power IC design. He noted that the die area for a digital control loop was much smaller. But that loop had to be on a very expensive fine-line CMOS wafer. That meant the masks needed to manufacture it had to be millions of dollars. Therefore, the part had to be high-volume, and it would be hard to make adjustments or changes if it required a new mask set.

If the part already was made in fine-line CMOS for a microcontroller or analog-to-digital converter (ADC), it might be very easy to add a digital-power controller for a small incremental cost. If the market was smaller or more volatile, an analog control chip would be better. If the chip needed big ESD (electrostatic discharge) diodes, well that would be cost-prohibitive on a fine-line process, which makes for another case for analog control loops.

Fuzzy Logic, digital power—it’s all about appropriateness and moderation. When I attended the Darnell Digital Power Forum in 2008, a presenter went through all of the Z-transform math used to analyze sampled-data systems. He noted that the equations took similar form to the classic control theory equations. Math just exists; it’s not superior or inferior. The theory that gets college professors so excited rarely makes for a vastly better product. It’s often the externalities that make the difference, like die cost or nonlinear exceptions.

This reminded me of another experience, this time with an ADC company. The firm raved about how its chip worked on charge, and that made it so much better. This didn’t sit right with me. I asked Nick Gray, then an ADC application engineer at National Semi. He noted, “You can do the math with voltage, or current, or charge. When it comes right down to it, it all ends up with a bunch of the same transistors.”

Keep this in mind when the next over-hyped technology comes into fashion. Be analog—don’t dismiss it out of hand, and realize it must have its good points. That is the way Pease dealt with Fuzzy Logic, and I sure miss his steady, skeptical rational voice.

About the Author

Paul Rako

Creative Director

Paul Rako is a creative director for Rako Studios. After attending GMI (now Kettering University) and the University of Michigan, he worked as an auto engineer in Detroit. He moved to Silicon Valley to start an engineering consulting company. After his share of startups and contract work, he became an apps engineer at National Semiconductor and a marketing maven at Analog Devices and Atmel. He also had a five-year stint at EDN magazine on the analog beat. His interests include politics, philosophy, motorcycles, and making music and videos. He has six Harley Sportsters, a studio full of musical instruments, a complete laboratory, and a video set at Tranquility Base, his home office in Sun City Center Florida.