Members can download this article in PDF format.

One of the more overstated idioms in the battery technology world is that batteries have come a long way since Alessandro Volta invented the voltaic pile in 1800. That’s accurate, of course, but mostly only since the broad commercialization of modern Li-ion chemistries (c. 1991, although there was some use of them as far back as the 1970s). A more analogous statement would be that battery management has come a long way.

Sponsored Resources

- How High-Voltage BMS Enhance Safety and Accuracy

-

LiFePO4 Battery Pack Platform for Up to 1500V

- Safer, More Accurate Energy Storage Systems

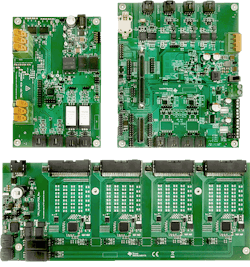

Today’s battery energy storage systems (BESS) have evolved to take on power demands across a variety of use cases. These range from residential to commercial and industrial applications, infrastructures, even grid-scale systems with voltage demands as high as 1,500 V (Fig. 1).

The chemistry of choice has become lithium iron phosphate (LiFePO4) because of its many advantages, safety, long cycle Life, thermal stability, high discharge rates, and environmental friendliness. Coupled with the latest sensing and power-management technologies, they help create a top-tier solution that takes high-voltage, energy storage systems to the next level—safely and reliably. This technology presents in the form of advanced battery-management systems.

Battery Nuances

All batteries are influenced by a number of factors—temperature, depth of discharge, overcharging, vibration—that adversely affect lifespan, safety, and performance. The BMS is tasked with monitoring these factors and more. In short, the BMS must ensure that the battery always remains within its specifications.

For any battery pack to function optimally, all cells in a pack should have the same specifications and tolerances. Unbalanced cells can cause a variety of issues, from slight performance degradation to thermal runaway. Balancing is fairly easy to accomplish during cell and pack manufacturing. But as cells age, these values drift, and not uniformly, so a solution is required to keep the cells balanced.

Mismatched cells limit the entire pack’s capacity, affecting the state of charge (SOC) and leading to inaccuracies in voltage readings. For example, during the charging cycle, within the flat region of the LiFePO4 battery curve, minor inaccuracies in a cell’s charge voltage can lead to incorrect SoC readings. This can result in either overcharging or undercharging; in the worst case, overcharging can lead to thermal runaway.

The BMS’s first order is to monitor and analyze system metrics such as cell and bus voltages, shunt currents, and impedances in real-time. In addition, it’s charged with protecting the cells from temperature and voltage extremes and short circuits, as well as regulating power and charging plus keeping the cells balanced.

Cell Balancing and Other Factors

Several methods can be employed to balance cells. The two most common approaches are active and passive. Active cell balancing is often preferred because it doesn’t reduce the energy within the pack as is the case with passive.

The passive method achieves SOC equalization by dissipating the energy from cells with higher voltages (which, in some cases, can be massive), usually via a fixed or switched shunt resistor or a charge shuttling circuit. It sets all of the cell voltages equal to the lowest one.

However, the lower the SOC, the larger the variances become in the state of the cells (as a percentage of total charge). So, while holding the SOC lower can increase cell life to some degree, chemical aging marches on, and disparities between cells worsen over time, degrading overall pack efficiency.

Moreover, there’s no balancing when the SoC is full. Still, it has some advantages, such as being less complex and expensive.

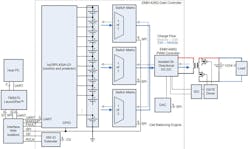

Active cell balancing (Fig. 2) is a technique to redistribute the charge state of each cell rather than wasting it by draining off energy.

It actively redistributes charge among cells, ensuring that all cells in a battery pack maintain similar voltage levels. This helps improve efficiency and extends battery life. Methods include inductive, capacitive, and DC-DC conversion.

For many applications, particularly very high voltage, the active method is better suited because it doesn’t waste energy by draining the higher capacity cells to the level of the lower capacity cells (as with passive cell balancing). Rather, it transfers energy by shuttling charge between the cells.

Another key metric is depth of discharge. It’s well known that draining batteries to exhaustion is extremely damaging to cells. Thus, the BMS must be aware of that and use various techniques, such as setting a low-capacity cutoff, removing it from the pack, or removing the entire pack if there’s a likelihood of full discharge.

Similarly, overcharging needs to be managed. Overcharging significantly shortens the life of a cell and, in extreme cases, can cause it to catch fire or explode. While LiFePO4 batteries are less sensitive to overcharging than other chemistries, they’re not immune. The BMS must integrate circuitry to prevent overcharging.

It’s About Safety

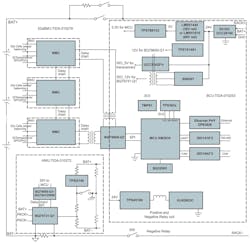

The BMS is also responsible for battery protection. The reference design shown in Figure 3 integrates a battery-management unit (TIDA-101279), a high-voltage management unit (TIDA-010272), and a battery-control unit (TIDA-010253). The high-voltage battery-pack monitor improves the resultant reliability and simplicity of calibration for isolation impedance measurements and contact welding detection.

The stackable battery monitor measures individual cell temperature using the BQ78076 14S integrated TI functional-safety compliance to ASIL B mechanism. When coupled with the battery-control unit (BCU), it ensures a high degree of control, safety, and reliability.

Conclusion

The BMS has evolved into a sophisticated battery interface for today’s advanced battery technology. Complex battery systems are becoming a power solution for many use cases, such as electric vehicles, alternative energy generation, power grids, backup power, data centers, and infrastructures of all types. Without the advances in battery management, much of this would still be waiting to launch.

Sponsored Resources

- How High-Voltage BMS Enhance Safety and Accuracy

-

LiFePO4 Battery Pack Platform for Up to 1500V

- Safer, More Accurate Energy Storage Systems