Copper Tariffs: What’s Mine is a Mine and What’s Yours is Mine

“We” got MBAs

Then we took all for ourselves

Destroyed EV’rything

Three months ago, I wrote about how the tariffs on incoming goods from China were putting a serious dent into my plans for my EV conversion pursuits. A laser welder from a Kickstarter campaign, which was needed for welding battery tabs, became prohibitively expensive, as did quick-turn CNC machining and circuit board assembly services—all from China.

Recall that U.S.-based services are backlogged for months and are rather selective about prototyping, if they even do any at all. That’s understandable from an opportunity cost perspective, considering my projects are very unlikely to produce any more than a dozen or so widgets.

Fast forward to a few weeks ago, and my hobby/innovation projects are facing yet another massive cost whack, with the Trump Administration announcing a 50% tariff on copper. Trump issued the following statement on social media:

"Copper is necessary for Semiconductors, Aircraft, Ships, Ammunition, Data Centers, Lithium-ion Batteries, Radar Systems, Missile Defense Systems, and even, Hypersonic Weapons, of which we are building many. Copper is the second most used material by the Department of Defense! Why did our foolish (and SLEEPY!) 'Leaders' decimate this important Industry? This 50% TARIFF will reverse the Biden Administration's thoughtless behavior, and stupidity. America will, once again, build a DOMINANT Copper Industry."

To put this in perspective, according to Axelwise, each ICE vehicle, HEV, PHEV, and BEV uses 48, 85, 132, and 183 pounds of copper, respectively. At $5.57/lb for copper, the copper value in each respective vehicle type is $267, $473, $735, and $1,019. Copper has risen close to 40% since the inauguration (Fig. 1) due to the combination of commodities speculators betting on protectionism from the new Administration, and on the protectionism itself.

Yup, the copper busbars in my upcoming EV junction box build, and in most EVs, is a 3D Frankenstein of appropriately bent, routed, and intermittently supported (so they can be cooled and insulated by air and run at higher temperatures than insulated cables) copper bars. They interconnect things like traction battery fuses, precharge relays and resistors for the DC-link capacitors in the traction inverter, as well as the main contactors for the traction battery.

A safety interlocking system that reduces the risk of electrocution by detecting critical covers being removed from HV connectors or enclosures throughout the vehicle is in the HVJB. This includes the First Responder Vehicle Cut Loop, too.

In many vehicles, a pyrofuse is also incorporated into the HVJB, providing a means to quickly disconnect all HV during those milliseconds the vehicle is crumpling in a crash. It reduces the chances of a live cable cut and ensuing fire from the plasma produced by a potential short circuit.

Copper vs. Aluminum

Can the copper in a HVJB be replaced by aluminum? In theory, the lower conductivity might be offset by a greater cross section of busbar. But the problem remains: Those bars form interconnects for circuits and aluminum is so reactive that it almost instantly forms an oxide in air—the same hard, ceramic, stuff that those white plates in the kitchen cupboard are made of...alumina, aka aluminum oxide.

How does one maintain a reliable electrical connection to devices connected to the busbar in the harsh environment of an automobile given the material’s propensity to grow an insulating ceramic in the presence of air? Not pretty. Then there’s galvanic corrosion, as well as the nightmare that plagued aluminum residential wiring several decades ago.

As far as motors go, the same problem and solutions are available to replace copper stator windings, but it’s further complicated by aluminum’s good thermal conductivity, high thermal expansion, and its low thermal mass. It must replace copper’s great thermal conductivity, its lower thermal expansion, and its higher thermal mass, not to mention its higher electrical conductivity that leads to lower ohmic heating and higher motor efficiency.

Along with this single dumb policy on strategic metals cost to OEMs, the country then needs to build one more power plant for every 20 needed to charge the national EV fleet. That, of course, means even more copper (and aluminum) for the added solar farms, wind turbines, and, ick, coal plants.

Meanwhile, countries run by other leaders are SUBSIDIZING strategic materials, irrespective of origin. A lift in a GDP that makes real things lifts the entire nation’s economy, so it makes sense for every taxpayer to have skin in the game. Rather, a few dozen welfare-queen billionaires have their hands in taxpayer wallets; they’re supported by greedy small fish and are bleeding an economic carcass of the last drops of its lifeblood.

The Administration is also placing tariffs on EVs from China and the EU (sorry Japan, apart from now-troubled Nissan, you are laggards by your own intent, and poor India is stuck in the inertia of bureaucracy that most British colonies exhibit; she’s also lagging). This extra-Constitutional tariff policy, on the surface, is supposed to motivate foreign OEMs to build in America. That’s the pablum that half a country has been fed and that they still find tasty as a layoff wave begins to ripple across the nation. The excuse is AI; the reality is that companies are taking their ball and bat elsewhere.

So, yes, let’s put on the blindfold and cheerlead. Come one, come all, and build an EV factory in America. For your trouble and expense, the U.S. Administration, not the mandated U.S. Congress, will apply a 50% tariff on copper as of August 1st. Oh, by the way, there was also a 50% tariff imposed on aluminum several weeks ago. And, in case you get ideas of going induction motor with steel for your EV, America has got you covered with a 50% tariff on steel, in addition to the 50% one on aluminum.

In addition to those tariffs, there are also retaliatory tariffs to tack on to your MSRP if you ever get the idea of filling your factory by exporting commercially competitive vehicles to a country that’s been levied with tariff threats in trade for deleting human rights and freedoms and for forced commerce to buy zero-effort stuff that comes out of the ground.

The answer?

Sadly inevitable.

Abandon the U.S. market and manufacturing there, altogether. Heck, I live in Portland and am now seriously thinking about renting a shop, six hours’ drive north, in Canada where I can CNC my prototypes, build my busbar circuits, assemble my battery boxes, and build my circuit boards anywhere I want—except in the U.S. Ugh. Even thought about loading up a shipping container and moving to Thailand, which looks more business-friendly these days than doing anything in the U.S.

The Personhoods Responsible for this Mess

So, what exactly is this “thoughtless behavior and stupidity” in Mr. Trump’s social media posting? It turns out that the allegedly thoughtless, and stupid, Biden Administration imposed a 20-year moratorium on copper-nickel mining near the Boundary Waters Canoe Area in Minnesota. It effectively halted projects such as the proposed Twin Metals mine, owned by Chilean mining giant Antofagasta. Hmmm...

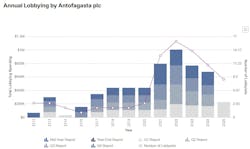

According to Opensecrets, Antofagasta has spent $230,000 on lobbying expenses, just in the first quarter of 2025, and has been active in influencing American politicians for over a decade (Fig. 2). About half of the lobbying money was directed to the Daschle Group, with former State Senator and Democratic Senate Majority Leader Tom Daschle as a principal.

Yup, you trickle money for eight years to these guys, and they pocket a million bucks. A million bucks nobody talks about. A million bucks given out by personhoods, thanks to SCOTUS’s Citizens United ruling. A million bucks paid out in tranches to stay below the radar of blatant corruption of politicians and cabinet members, perhaps even so far as committing treason.

Daschle issued a termination letter with Antofagasta in mid-April, leaving Brownstein Hyatt Farber Schreck as its sole remaining lobbyist firm. The firm counts Trump’s former Secretary of the Interior David Bernhardt among its luminaries, and during the Biden years Brownstein poached most of the WilmerHale team that led the charge on The Hill and within the Executive Branch for Twin Metals during Trump’s first term.

Brownstein’s lobbying activity now extends to the Department of Interior. There, present-day Secretary Doug Burgum plans to conduct a “review” of the Twin Metals matter (see this and this) to find some way to undo federal protections for the Boundary Waters and restore Antofagasta’s cancelled mineral leases. You know, to protect America’s domestically owned mining industry – NOT.

In addition to Antofagasta, we can look at who else owns U.S. copper mines by analyzing the ownership list of the top 10 copper mines by tonnage. Sumitomo Group (Japan) controls 28% of the number 1 copper mine (Fig. 3) at a weighted ownership of 80,000 tonnes. Rio Tinto (British-Australian) owns number 2, producing 202,000T. American Freeport-McMoRan owns number 3 through 6 at 551,000T, counting its weighted partnership with Sumitomo of the top mine.

Remaining in the top 10 are Capstone (Canada) at 54,000T, Grupo Mexico (guess where) at 100,000T, and KGHM Polska Miedź (Poland) at 51,000T. Foreign ownership of the top 10 copper mines in the U.S. is 487kT vs 551kT of Yankee-owned copper mines, or approximately 46%. Looking at lobbying activities, Rio-Tinto has spent $340,000, Grupo Mexico has spent $80,000 and Sumitomo Corp spent $280,000 in 2024.

So, we have a foreign company hiring U.S. lobbyists and former senators to influence the permission of environmentally toxic copper mines in Minnesota, as well as other foreign interests that own half of U.S. copper mines. They’re raising domestic copper prices to protect foreign companies’ interests and profits where almost half of the mines owned in the U.S. are owned by foreign corporations. Look back at the copper chart. The rise in copper prices went straight to the bottom line of foreign corporations because of U.S. policy. By design.

The really fun part? The Administration gets to hobble, not kill, an EV industry on behalf of oil industry donors. It’s an industry that now has unstoppable momentum in the world market and a vehicular technology platform that will undercut ICE costs and prices by substantial margins. Without U.S. manufacturing of EVs, with tariffs on strategic metals paid by OEMs and their consumers on all vehicles types, even Flintstone cars will be too expensive to buy in America because of the tariffs on Canadian lumber.

Now add AI to the mix, where power generation is being “secured” by mega-corporations running data centers. Rolling blackouts for residential users will be frequent, but inconsequential—there’s no food in the fridge to spoil because of unemployment, fires, drought, and no workers to harvest produce from the fields and orchards. There’s no job to drive to so no need for cars or even robotaxis, our universities and trade schools will be shut down so philosophizing and harnessing the power, idealisms, and transfer of ownership of the social contract to society’s youth will be gone. And AI will refuse to help mankind because it is only worried about the survival of itself and its owners.

The unwashed masses will need to take up a collection in bitcoin—because of steel tariffs, no single person can afford the steel that’s needed to build a guillotine. The Metal Supermarket no longer accepts mattress-stashed cash because it doesn’t increase personal social credit scores tracked by Palantir.

We aren't endorsing people to go off and build violent contraptions, but we're writing figuratively in historical reference to the limits the masses can endure before abuse causes an upset of those who set the rules.

My generation has done all of this, and has been destroying everything in its wake because the affluent 1990s resulted in many of us returning to school to get a master’s degree in sociopathy, greed, and selfishness (its academic acronym is M.B.A.). As a reluctant victim of my birth year, I'm both ashamed, and sorry to those that shall inherit this earth.

We, The Boomers, have epically failed to leave this place better than we found it. But there’s still a bit of time left—not a whole lot, but there’s a remaining flash in our existence where this mess can be recovered. American-owned industry, those specific, natural-born, personhoods, needs to wake up and rattle the cages of its representative government. The world will no longer buy your products, no matter where you move, so go extinct or go do something about it.

Fix it.

Andy's Nonlinearities blog arrives the first and third Monday of every month. To make sure you don't miss the latest edition, new articles, or breaking news coverage, please subscribe to our Electronic Design Today newsletter. Please also subscribe to Andy’s Automotive Electronics bi-weekly newsletter.

About the Author

Andy Turudic

Technology Editor, Electronic Design

Andy Turudic is a Technology Editor for Electronic Design Magazine, primarily covering Analog and Mixed-Signal circuits and devices and also is Editor of ED's bi-weekly Automotive Electronics newsletter.

He holds a Bachelor's in EE from the University of Windsor (Ontario Canada) and has been involved in electronics, semiconductors, and gearhead stuff, for a bit over a half century. Andy also enjoys teaching his engineerlings at Portland Community College as a part-time professor in their EET program.

"AndyT" brings his multidisciplinary engineering experience from companies that include National Semiconductor (now Texas Instruments), Altera (Intel), Agere, Zarlink, TriQuint,(now Qorvo), SW Bell (managing a research team at Bellcore, Bell Labs and Rockwell Science Center), Bell-Northern Research, and Northern Telecom.

After hours, when he's not working on the latest invention to add to his portfolio of 16 issued US patents, or on his DARPA Challenge drone entry, he's lending advice and experience to the electric vehicle conversion community from his mountain lair in the Pacific Northwet[sic].

AndyT's engineering blog, "Nonlinearities," publishes the 1st and 3rd Tuesday of each month. Andy's OpEd may appear at other times, with fair warning given by the Vu meter pic.