Quality problems bring PV testing to the fore

The third-party testing organization STS found something interesting when it reviewed its figures for defect rates of Chinese photovoltaic modules: It discovered that 8% of the modules it tested last year were defective straight from the manufacturer.

So says Senergy Testing Solutions (STS) general manager Thibaut Lemoine. STS, which developed proprietary quality standards for the PV industry, tested 77,700 PV modules in 2011 in its Kunshan, China facility. The troubling thing about the 8% defect rate STS noticed was that the rate is based on tests of only relatively few units -- compliance with IEC and/or UL standards only requires eight to ten unit samples. And the samples used for compliance testing aren’t representative of the typical product coming off the production line, Lemoine says. So the real defect rate that users actually see could conceivably be much higher, Lemoine speculates. The implications for PV users are grim: Today, 60% of the PV modules being installed worldwide are produced in China by several hundred manufacturers located there. You might think that quality wouldn’t be an issue because more than 85% of those manufacturers are certified against IEC/UL standards and 95% of them provide a product and performance warranty.

But PV module warranties typically have a lot of fine print. They often don’t cover specific kinds of settings such as marine environments, Lemoine says. And they generally don’t cover the cost of transportation, removal, and re-installation, nor do they cover the loss of revenue while the panel system is down.

Even worse, IEC/UL compliance doesn’t require tests of PV modules coming off the production line -- the test cells can be hand selected. And Lemoine sees quality problems arising because the price of PV panels has been cut in half over the last 12 months. To compensate, manufacturers are using cheaper components which aren’t qualified, Lemoine says, a practice likely to make any existing quality problems worse.

Many of the quality issues Lemoine mentions pertain to mechanical issues. For example, STS has noted cracks in modules caused by thermal stresses over time. About half the defects STS found related to workmanship problems on the module. And, he points out, a defect in a single PV cell degrades the performance of the entire array. STS estimates that in some cases, quality defects can reduce the total production of electricity by almost 30% over the life of the array.

To head off such difficulties, Lemoine suggests PV users buy only from manufacturers that not only have quality certifications, but also which monitor their production processes to ensure their process parameters are under control and that they are using qualified components and materials. He also suggests using independent testing facilities to assess the quality of what’s coming off the production line.

But what kinds of production tests might be advisable? Guidance on this point comes from Arturo Herrero, chief marketing officer of PV module maker JinkoSolar. Herrero says his company runs 16 different tests during production to assure quality levels. These tests include not just powering up finished cells to look for short circuits; they also include special tests to identify hot spots on the cells caused by flaws such as microcracks. Also in the JinkoSolar test regime are tests of modules designed to uncover performance degradation over time, a pull test on module leads, a test for leakage current when the modules are wet, an insulation test, thermal cycling tests, and ground continuity tests.

Because of continuing troubles from defective PV modules, testing organizations are trying to come up with new approaches that go beyond today’s IEC and UL standards to give a better feel for how PV modules are likely to behave over their typical lifespan. So says Claudio Ferrara, who heads up the Fraunhofer Institute for Solar Energy Systems in Germany. Over the past five years, Fraunhofer has tested 1,776 PV modules for IEC qualification. Surprisingly, about 20% of the modules failed in testing, Ferrara says.

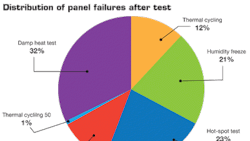

Specifically, Fraunhofer has noted 20 major failure modes such as substrate bubbling, cell breakage, corrosion of cell connections, delamination of the solar cell backsheet, discolored bus bars, hot spots on the panel, microcracks, and oxidation on the busbar. Several kinds of failures show up during damp heat tests when humidity penetrates the cell structure and causes chemical reactions on various cell components. Similarly troubles arise during hot spot tests, which simulate the reverse biasing of a cell that can happen when it is shaded while other cells in its string are still in the sunshine. Here Fraunhofer technicians noted numerous defects in the polymer cell coatings such as bubbles and holes.

Fraunhofer also noted a number of defects in PV cell materials. In front and/or back cover glass, for example, there were instances of corrosion, abrasion, frosting, and breakage. Metal frames, connectors, cables, and other connections experienced distortion, stripping, corrosion, and disconnections. Module backsheets, cable insulation, the polymer front cover, and adhesives experienced problems that included delamination, blistering, yellowing, cracks and embrittlement, and penetration of sealants from humidity.

Ferrara says there are R & D projects underway that are investigating how environmental stresses lead to various failure modes. And testing organizations are trying to get a better handle on PV module degradation by coming up with ways of detecting degradation faster -- raman spectroscopy, which examines a material’s chemical bonds, looks like a promising technique, Ferrara says.

But in a nutshell, the current set of PV standards don’t address wear-out failure modes and don’t estimate the lifetime one can expect from a given PV module. Fraunhofer is now trying to come up with test regimes that do just that. Specifically, the organization wants to rank PV modules relative to their likelihood of performing reliably over their service life. It would purchase modules through existing distribution channels for testing so manufacturers couldn’t skew results by cherry picking. This would also mean tests would implicitly factor in stresses that arose during shipment of the panels.

The tests Fraunhofer has in mind would be continuous and would look for changes in panel behavior over time. They would, for example, look for increases in leakage current or degradation in power output, as well as noting physical changes such as film delaminations, discoloration, or embrittlement. The tests Fraunhofer has in mind to expose these problems include high voltage stress, damp heat and UV tests, mechanical loading and thermal cycling, as well as simply running the panels for a year outside and noting how they hold up.

Resources

Fraunhofer Institute for Solar Energy Systems, www.ise.fraunhofer.de

Senergy Testing Solutions (STS), www.sts-certified.com

JinkoSolar, www.jinkosolar.com/

Measuring photovoltaic devices accurately

Neil Forcier

Agilent Technologies Inc.,

Englewood, Colo.

Many tests of photovoltaic (PV) devices essentially involve measuring the cell’s current/voltage (IV) curve. Other tests such as capacitance and time-domain waveforms may also be used, but the IV curve is the mainstay.

Depending on the maximum current, voltage and power it can deliver, a general-purpose source/measure unit (SMU) can perform illuminated and dark tests for research and developmen purposes. The optimal choice is a four-quadrant SMU, which enables complete IV testing. Benchtop units that include a graphical interface and task-specific viewing modes can accelerate testing, debugging and characterization.

General-purpose modular power supplies that sink current can support illuminated and dark tests. As with an SMU, the optimal choice for IV testing is a four-quadrant supply; however, two-quadrant models, when combined with polarity-switching relays, can handle solar cell characterization. In either case, multi-channel models will support parallel testing in manufacturing applications.

Some specialized instruments are also well-suited to PV applications. For example, a semiconductor device analyzer that provides IV and capacitance/voltage (CV) measurements can run illuminated and dark tests in R&D. These capabilities are used to measure or calculate a variety of essential solar cell characteristics.

A variety of pitfalls can affect measurement results. One common source of error is the output of an artificial light source, which can cause tremendous variation in illuminated tests. Variation comes from issues such as noise, wavelength drift, phase differences and flicker. As a rule of thumb, these variations add at least 1% error to any measurement.One way to address the problem is with a reference solar cell. Such a cell is one that has had its short-circuit current calibrated with respect to three variables: reference spectrum, total variance and temperature. Such cells are available commercially. As an alternative, existing cells can be sent for calibration by an organization such as the National Renewable Energy Lab (NREL) or an ISO 17025-accredited operation such as Newport Corp. or VLSI Standards Inc.

The reference solar cell need not resemble the device under test (DUT). Rather, it provides a known quantity for measurement. In practice, the PV reference cell is used to minimize the spectral-mismatch error that arises from light source variations and the relative responsivity of the DUT.

Here’s how the reference cell helps reduce error. First the solar cell under test is illuminated and instrumentation captures its IV-curve. The reference solar cell is placed in close proximity and its short-circuit current is concurrently captured using hardware-based triggering. The reference cell has a known short-circuit current, so this current level provides a measure of the light source output. For example, if the expected short-circuit current of the reference solar cell is 1 A and the measured short-circuit current is 0.9 A, then the light source output was 10% less than expected. Measurements of the DUT can then be mathematically compensated by 10% to account for the variation in light-source intensity.

Of course, this scenario is a bit simplistic. Mathematically compensating the output of the DUT does not ensure a 1-A output if the light intensity had been 10% brighter. In addition,other factors may cause the unexpectedly low output current: temperature variation, contact resistance, reference cell aging and drift, and more.

Taking a broader view, there are myriad sources of error—including the fundamental current and voltage measurements. Standards such as IEC 60904-1 and ASTM E948 or E1036 provide benchmarks. For example, ASTM requires that short-circuit current and open-circuit voltage be measured with a total uncertainty of less than 0.1% and with resolution of 0.05%. IEC specifies an accuracy of 0.2%.

Many commercial testers can provide this accuracy at full scale. Better, though, is to use a tester that can provide such accuracy at one-tenth of full scale, the region in which measurements tend to happen in the real world.

Facilities that use dedicated test systems should consider two potential drawbacks inherent to this approach: These systems tend to be less flexible than general-purpose equipment and fewer people in-house will understand the nuances of their operation. A dedicated, single-purpose test system can be up and running quickly. Unfortunately, such systems can be tough to repurpose for a new solar cell or a different application. If the system has a closed architecture, where its interface specifications aren’t public, users may have difficulty optimizing its performance.

Test systems based on general-purpose and specialized instrumentation have notable benefits. The technical staff is more likely to discern the intricacies of instrument operation. Consequently, they can be more creative about optimizing the test system and repurposing its individual system elements if need be.

Solar cell parameters measured or derived from IV measurements

• Short-circuit current

• Short-circuit current density

• Open-circuit voltage

• Maximum power point, Pmax

• Current at Pmax

• Voltage at Pmax

• Fill factor

• Conversion efficiency

• Shunt resistance

• Series resistance

Solar cell parameters measured or derived from capacitance measurements

• Parallel capacitance

• Carrier density

• Drive-level density

Resources

Agilent Technologies, Inc.,www.agilent.com