Open-Source Platform for Smart Ventilators/Respirators Enters COVID Battle

In response to the COVID-19 pandemic, the Trinamic Open Source Ventilator (TOSV) initiative has released a new development platform. It’s intended to accelerate the design and manufacture of cost-effective ventilators respirators, laboratory automation equipment, and other applications where a controlled-flow air supply is required.

The open-source design deliberately uses common, readily available components to control BOM costs and avoid the longer lead times of components traditionally used in medical products. With the cost of a hospital-grade ventilator typically running between $25K and $50K, Trinamic hopes that this effort, and those of organizations like Nvidia, Renesas, and especially the Open Source COVID 19 Medical Supplies (OSCMS) project, will lead to more plentiful supplies and lower prices for these and other life-saving devices.

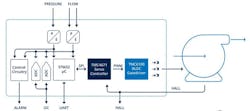

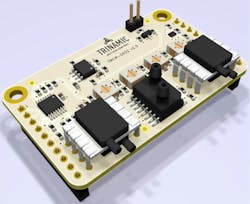

Trinamic's reference design and associated development kit (TMC4671+TMC6100-REF-TOSV) uses a dynamically controlled high-RPM turbine, driven by a BLDC motor. It features a smart BLDC motor/servo controller, an array of digital I/O and analog inputs, a Raspberry Pi-style session-border-controller (SBC) connector and an interface for an add-on pressure sensor board (Fig. 1).

The dynamic control scheme allows the use of pressure and volume sensors to support either pressure-controlled or flow-controlled ventilation modes (Fig. 2). The board's BLDC servo driver is capable of delivering currents of up to 6 A rms while operating from supply voltages ranging from 12 to 36 V.

Two Important Takeaways

As noted earlier, there are lots of open-source ventilator designs in various stages of development, but several interesting and potentially important things currently distinguish this platform from many of those initiatives.

First, this design can produce the complex air flow and pressure regimes needed to keep COVID patients’ lungs working and uninjured for weeks at a time. This contrasts with many of the early open-source designs known as “bag bangers,” which are based on manually operated portable respirators used by first responders while transporting patients. In all of the cases I've seen so far, these designs deliver poorly controlled air flows that can severely damage a patient's lungs within a matter of days.

Even some more rudimentary blower-based systems can't support new techniques that are helping improve a patient's odds of survival. For example, we've learned that leaving a patient's lungs slightly pressurized at the bottom of the exhalation phase can avoid or even reverse the collapse of the cilia's walls and sticking to each other.

Trinamic's motor controllers are inexpensive and well-suited for this task. The company has already distinguished itself in the ability to use its powerful on-chip processors to implement complex control loops that solve a surprising number of pesky motion-control-related problems in 3D printers, industrial automation equipment, and other applications (Fig. 3). This includes using complex acceleration/deceleration algorithms and control loops to help 3D printers achieve higher speeds and greater precision while dramatically reducing the noise produced by their stepper motors.

Having seen this in action (as opposed to .ppt slides), I'm hopeful that the company will be able to help developers implement the many subtle functions that respirators and ventilators must do to work in harmony with a patient's lungs, rather than slowly damaging them.

Second, since Trinamic only makes motor/motion control devices, it’s pretty much agnostic about the rest of the components in the BOM. As a result, the company’s design is driven by functionality and costs, rather than how many of the other firm's products can be included in the design. In the end, this translates into a more affordable BOM and, equally important, components that are more likely to be available when needed.

The Next Steps

If you want to learn more, click here for a copy of the development kit's datasheet.

In addition, Trinamic is using GitHub as the repository for its TOSV project. You can visit https://github.com/trinamic/TrinamicOpenSourceVentilator-TOSV to download an extensive set of files, including:

- Module design, layout, and manufacturing data for the TMC4671+TMC6100-REF-TOSV

- Module design, layout, and manufacturing data for the TOSV-SENSOR-REF

- Complete firmware sources and Eclipse CDT-based project files for the TMC4671+TMC6100-REF-TOSV

- User interface project for a Raspberry Pi plus display for an example ventilator application

- Link to Grabcad for an example of a full housing with display, Raspberry Pi, TMC4671+TMC6100-REFTOSV, and tube connections