Are there PSE and PD ICs that can handle higher loads than the current IEEE 802.3at PoE spec?

Christopher Gobok is a product marketing engineer for mixed signal products at Linear Technology. Chris graduated from San Jose State University with a BSEE, MSE and MBA. His previous industry experience includes working as a PME with optoelectronics and power MOSFETs.

QUESTION: Is it possible to provide an IC for the power sourcing equipment (PSE) and another for the powered device (PD) in a PoE system that can handle higher loads than the current IEEE 802.3at spec?

ANSWER: Yes, Linear Technology offers many controllers that utilize LTPoE++, a high power Power over Ethernet (PoE) standard that uses a single CAT-5e Ethernet cable to provide four different power levels: 38.7W, 52.7W, 70W and 90W. These LTPoE++ power levels allow external components in the power path, such as MOSFETs, transformers and DC/DC converters, to be sized accordingly so designs can be optimized both in terms of cost and efficiency. LTPoE++ is interoperable and backward compatible with both IEEE 802.af PoE and 802.3at PoE+ standards, so LTPoE++, PoE+ and PoE devices can all be mixed and matched.

As shown in Fig. 1, LTPoE++ has a simple plug-n-play nature so power sourcing equipment (PSE) and powered device (PD) controllers can seamlessly connect, classify and communicate with one another – coding with Link Layer Discovery Protocol (LLDP) is not required.

With a complete end-to-end solution that requires no additional code, LTPoE++ PSE and PD controllers can power a wide variety of power hungry applications, including heated outdoor surveillance cameras, point-to-point dish antennas and pico cells.

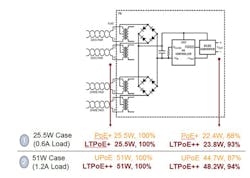

Behind LTPoE++’s simple nature are controllers that address today’s most complex PoE designs. Increasing power efficiency and minimizing heat dissipation in the PD is usually top priority and are dictated by the losses in the input diode bridge, power MOSFET and DC/DC converter used. Fig. 2 shows a generic PD schematic and compares efficiency calculations for two PD solutions at two different power levels.

In the 25.5W case where a 0.6A load is assumed, the PoE+ PD uses eight standard HD01 diodes in the two diode bridge rectifiers, an LTC4265 PoE+ PD controller with an integrated 1.0Ω MOSFET, and a 94% efficient DC/DC converter – resulting in 88% total efficiency from the PD input to the DC/DC converter output. By contrast, the LTPoE++ PD replaces both diode bridges with an LTC4321 ideal diode bridge controller and eight 0.1Ω MOSFETS, uses an LT4275 LTPoE++ PD controller with an external 0.1Ω MOSFET, and uses the same 94% efficient DC/DC converter. Comparing the figures at the PD output shows that the LTPoE++ PD is 5% more efficient and provides 1.4W more power to the load. A similar comparison was performed in the second case at 51W with a 1.2A load, between a Cisco UPoE PD (LTC4265 based) and an LTPoE++ PD (LT4275 based) – at the higher power level, the LTPoE++ PD is 7% more efficient and provides about 3.5W more power to the load.

LTPoE++’s higher power efficiency ultimately translates to some important real-world advantages for end applications and customers. The most obvious advantage is that extra power to the load could be used for more value-added product features, features which would otherwise be unavailable especially at lower power levels where even an extra Watt can really make a difference. Conversely, PDs wanting to stay below a certain power level for classification or PSE availability reasons can more easily do so without sacrificing features. For some customers, it may simply be the lower system power consumption and total cost of ownership that gives them the competitive edge.

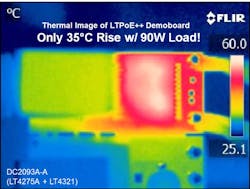

Managing heat is especially challenging with many PoE designs because small tight enclosures are usually desired but may be at the mercy of large costly heat sinks. The efficient design of LTPoE++ solutions reduce heat sinking requirements and allow for a smaller products. Fig. 3 shows an impressive thermal image of a 90W LTPoE++ PD demo board experiencing only about a 35°C rise at room temperature, attributed to the low RDS(ON) MOSFETs being controlled by the LT4321 diode bridge controller and LT4275 LTPoE++ PD controller.

Linear Technology offers single, quad, octal and 12-port LTPoE++ PSE controllers with lowest-in-industry power dissipation, robust ESD and cable discharge protection, low component count and cost effective designs. These 4th generation PSE controllers are IEEE compliant, use 0.25Ω sense resistors to lower power dissipation, and use a high reliability 4-point PD detection scheme to eliminate false PD detections. External MOSFETs, a scalable cable discharge protection scheme, an 80V abs max rating on all analog pins, and overtemperature protection all ensure robust operation. Off-the-shelf single port 70W injectors from Altronix and Eten Networks are already available in the market and ready to support LTPoE++ PDs. Linear Technology’s LT4275 LTPoE++ PD controller flawlessly syncs with any LTPoE++ PSE controller. Traditional PD controllers that integrate the power MOSFET are ideal solutions for space-constrained applications. However, the LT4275 uses an external MOSFET which allows designers to size the MOSFET per their application’s exact efficiency and heating requirements, enabling the use of low RDS(ON) MOSFETs on the order of 30mΩ. The LT4275 also has a wide -40°C to 125°C operating temperature range, 100V abs max rated port pin, and overtemperature protection to ensure robust operation. As discussed, when coupled with the LT4321 diode bridge controller and a 94% efficient DC/DC converter, customers are able to easily build high efficiency, cool running PDs that far exceed 802.3at power levels.

For a complete list and to learn more about LTPoE++ controllers, visit:

Linear Technology Products > Power-Over-Ethernet Interface Controllers