|

For more information on DMM accuracy, |

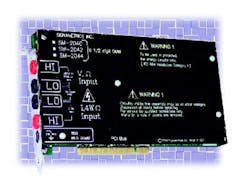

Present-day benchtop and rack-and-stack automated test systems pre-dominantly utilize IEEE 488 digital multimeters (DMMs) while PC-based test systems tend to use data acquisition boards as the primary measurement instruments. This is because PC plug-in DMMs have not been around very long, and many of the early plug-ins failed to meet the requirements of benchtop and system DMMs.

Fundamental differences between PC plug-in DMMs and data acquisition boards can make a difference in the test application. Data acquisition boards are a good, economical choice for many applications, particularly when it comes to handling a large number of channels at sampling rates less than 500 S/s.

On the other hand, DMMs require additional scanning or multiplexing hardware to handle multiple channels. The maximum rate for most modern PC plug-in DMMs is 60 to 200 measurements/s; a few have measurement rates as high as 1,000/s. In many data acquisition board applications, averaging is used to reduce noise which results in lower throughput.

In applications where the required sampling rate can be handled by a PC plug-in DMM, consider the advantages carefully. Part of the decision process is the trade-off in speed vs. accuracy.

A DMM’s accuracy tends to decline faster with measurement rate than that of a data acquisition board. Of course, at slow sampling rates, a DMM’s accuracy is much higher than that of a data acquisition board, so it still may be the better instrument, even when used at higher speeds.

To be certain that you have made the right choice, read the specifications carefully. If you’re still not sure, discuss your application with the vendor.

A very significant factor in a DMM’s performance is its high-voltage isolation barrier that presents extremely high impedance between the input terminals and the host PC and ground. It prevents ground loops, helps reject common-mode noise, and makes DMMs truly differential measuring instruments.

One advantage of a true differential input is the capability to measure a few microvolts of signal while the input terminals are elevated to several hundred volts DC or AC common-mode. The differential topology gives predictable and repeatable test results, independent of the test environment.

Single-ended measurement systems can produce headaches. In one case, although the test system performed well during the development phase, noise problems were encountered when it was moved to an off-shore production facility. In contrast, the reason most DMMs can provide at least 16 bits of resolution is the good noise rejection.

Overall, if lower measurement rates are acceptable for an application, a PC DMM has several attributes that make it a better measurement tool. Some of these include a much higher resolution, better accuracy and stability, greater versatility, and excellent noise rejection.

Although DMMs are not considered to have signal conditioning, they have built-in isolation, current sources, frequency counters, rms converters, current shunts, four-wire Kelvin sensing, and software to measure a variety of sensors. These features eliminate the need for additional signal-conditioning hardware while facilitating the acquisition of many different types of signals with great accuracy.

While data acquisition boards may use successive approximation register analog-to-digital converters (ADC) and a sampling front end, most DMMs use a high-resolution, integrating type of ADC with a controlled conversion cycle. In conjunction with the isolation barrier, an integrating ADC provides exceptionally high power line and differential noise rejection. This is a significant benefit because power-line voltages, currents, and their harmonics are major contributors to noise in the test environment.

Versatility

Using data acquisition boards for complex measurements requires the addition of signal-conditioning hardware. Functions such as low-pass filters, current sources, isolation amplifiers, and attenuators can be added to enhance the capabilities of the measurement system. Signal conditioning can reduce measurement noise, provide stimulus for passive components such as resistors and RTDs, and allow the measurement of a variety of sensors.

Even with the addition of signal-conditioning hardware, the performance remains limited by the capability of the digitizer. Compare this to the cost and capabilities of a PC based plug-in DMM with signal conditioning, measurement facilities, and software.

Measurement capabilities for PC DMMs include two-wire and four-wire resistances, rms-ACV, rms-ACI, DCV, DCI, frequency, period, temperature, diodes, and RTDs. Signal conditioning is built in without add-ons and with several decades of measurement ranges from microvolts to several hundred volts, nanoamps to a few amps, and milliohms to megohms.

Things to Look For

The application should drive the selection of a DMM. There is no reason to spend more than the job requires, but a wise choice will go a long way.

If test-system reliability is important, you will find that some PC DMMs exhibit more than 75,000 hours of mean time between failures. PC plug-in DMMs are reliable because of their lack of displays, data cables, and connectors; low power consumption; and few mechanical and electromechanical components.

It is important to evaluate the software interface that forms part of the PC plug-in DMM. Always try to use open control software that does not require the purchase of additional drivers. For instance, with generic software packages such as Visual Basic or C++, you can be assured of a very straightforward interface to the DMM’s DLL without using additional components. Visual Basic has a very quick learning curve and an open architecture. If time is of the essence, consider it for your test application.

Finally, most suppliers will accept a unit back within 30 days. Take advantage of this offer, and don’t hesitate to send it back if it does not meet your expectations—even if it does meet its specs. Before you decide to return a unit, try to contact the vendor’s technical support. This usually helps to clarify the issues.

|

For more information on DMM accuracy, |

About the Author

Tee Sheffer is the cofounder of Signametrics. Prior to his affiliation with the company in 1991, he was a senior staff engineer and a project manager at Fluke. Mr. Sheffer received undergraduate and graduate EE degrees from the University of Washington and holds 10 patents in the area of test and measurement. Signametrics, 6073 50th Ave. NE, Seattle, WA 98115, (206) 524-4074.

Return to PC-Based Test Online – Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 1999 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

August 1999

|

|