Performing Functional Testing of ADSL Modems In a Manufacturing Environment

With more than 750 million phone lines in the world today, the potential for asymmetric digital subscriber line (ADSL) products is enormous, and the production of modems and equipment is expected to grow exponentially (Figure 1). DataQuest predicts that more than 15 million customer premise equipment (CPE) units will be deployed by the year 2001.

Figure 1.The assurance of reliable ADSL products and services depends heavily on functional testing during the manufacturing process. The subject of what and how to test often is debated.

A functional test is used during the final stages of modem manufacturing to simulate an ADSL physical-layer link and data transfer. In setting up the ADSL test platform, it helps to have an understanding of the traditional operating equipment for ADSL. An ADSL link requires both standard-compliant (standards include ANSI T1.413.2, ITU G.992.1, and G.992.2) central office (CO) and CPE.

CO ADSL equipment often is defined as a digital subscriber line access multiplexer (DSLAM). However, traditional plain old telephone service (POTS) equipment such as a digital loop carrier (DLC), a remote access multiplexer (RAM), or phone switch systems also can be upgraded with the addition of ADSL line cards.

Access provider equipment is cumbersome and costly for testing CPE devices in the lab or during production. Also, the availability of and support for this equipment are catered toward large-volume purchases, not production or lab testing. Test devices such as Aware’s Veritas Test System emulate the operation of CO ADSL equipment, serving as an efficient alternative due to space and cost advantages and flexible software.

As an industry benchmark, an automated functional test should run 60 to 120 seconds for optimum efficiency. This efficiency requires automation software to configure and manage the test and the test equipment. Also, a low false-failure rate can be achieved with robust test procedures and high-quality test equipment. This equipment includes a CO emulator, a wire-line simulator, and a data-termination device.

The CO emulator acts like a golden ADSL modem. It must support multiple test configurations for future generations of CPE ADSL silicon solutions and emerging broadband technologies such as voice over DSL (VoDSL) and ADSL over an integrated services digital network (ISDN).

The CO emulator should meet this criterion and integrate advanced remote management software for custom link setups. The custom link setups will migrate from intense testing to a limited functional test as the modem life-cycle grows. The emulator also should be configured to log data, facilitate a data transfer, and diagnose common modem problems.

A wire-line simulator, available from DLS TestWorks or Telebyte, can simulate loop lengths from 9,000 to 12,000 ft, a distance typically covered in the traditional modem operating environment. Data termination with an actual data transfer completes the functional test. This data can be generated in a traditional serial form using a TTC FireBerd or a Consultronics PUMA bit error rate tester (BERT). As an alternative, quality of service (QoS) testing can be performed using the transmission of raw ATM cells. This also allows the use of Internet protocol (IP) level applications such as the file transfer protocol (FTP) to analyze data quality (Figure 2).

Figure 2.

The Test Area

Because ADSL is susceptible to environmental disturbances, it is important to isolate the test area from disturbances that could interfere with test results. An optimal test area should be confirmed through careful test and observation, rather than convenience. Specifically, manufacturers will want to:

- Space equipment and run phone line cables away from all potential noise sources, including power lines, Ethernet cables, monitors, and power supplies.

- Use a high-quality uninterruptible power supply (UPS) to help ensure a clean and reliable source of power.

- Shield the test environment from outside interference, such as AM radio transmissions.

- Connect all test devices to a common ground to reduce ground loops.

Functional Test Procedures

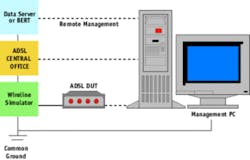

Although actual test procedures differ based on the supported modem technology, interfaces, and device drivers, Figure 3 represents a typical sequence of events. Test procedures will vary among manufacturers since each enters a different stage of the modem life cycle. As modems mature and failures become known, a manufacturer can reduce or modify certain test procedures. Recommended procedures for testing an ADSL modem during production are described in Table 1.

Table 1. Procedures for Testing an ADSL Modem During Production

| Physical Modem Test |

An initial request identifies the modem by reading a manufacturer serial number, a bar code, or a user-entered field. This test also confirms the modem interface, power, and communications channel. |

| Firmware Load | An optional firmware flash or upload verifies the presence and functionality of the ADSL chipset. This process also loads custom firmware onto the modem for testing. |

| Link Initialization | Using a configured line simulator and a DUT, a link is initialized with the CO emulator. The link time and hand- shake data are monitored to ensure a fast, reliable connection. |

| Confirm Data Rates |

The ADSL connection is measured for upstream and downstream rates. These rates may vary slightly with each test, prompting the need for a threshold setting. The threshold setting determines the acceptable variance between modem test results. |

| Connection Integrity |

Viewing basic link characteristics validates the ADSL connection. Link variables include the following:

|

| Data Transfer | For a serial data transfer, a BERT device transmits a bit pattern; this method provides physical-layer authentication. The test also requires a PC-based utility to receive the stream and regenerate an upstream bit pattern. If this software utility is not available from the modem or chipset designer, an ATM test is recommended. ATM25 or Ethernet interfaces stream data directly from an HTTP or FTP server. In the case of an FTP download, software can be configured to download, measure the download time, and compare the data to ensure its integrity. This test method is more complicated than physical BERT because it requires the configuration of higher protocol layers. |

| Reporting | Logging of modem test data should be enabled from the initial test. This data evaluates test efficiencies and reduces the time needed to diagnose failed modems. |

Summary

It is important to understand the value placed on quality test equipment, the test operating environment, and the procedure for performing functional modem tests. The critical component to facilitate testing and diagnostics is the CO emulator.

Systems need to incorporate robust software and functionality to emulate CO equipment and provide full support for standard-compliant DSL technologies. Using these functional test recommendations, manufacturers can meet the growing demand for ADSL modems and ensure high-quality production efficiencies.

References

- ADSL Market Growth, DataQuest.

- ITU G.996.1, Test Procedures for Digital Subscriber Line Transceivers.

- ANSI T1.413, Network and Customer Installation Interfaces.

About the Author

John Smits is the ADSL product manager at Aware. Before joining the company in 1997, he held marketing positions at Cascade Communications. Mr. Smits received a B.S. in marketing at Bentley College. Aware, 40 Middlesex Turnpike, Bedford, MA 01730, (781) 276-4000, e-mail: [email protected].

Published by EE-Evaluation Engineering

All contents © 2000 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

July 2000