Board stress analysis (BSA) has been a useful tool for designers and fixture manufacturers for more than a decade. This tool has allowed designers to minimize induced stresses on the printed circuit board (PCB) under test and nearly eliminate the potential for damage. Until recently, it was practical to perform only a two-dimensional (2-D) analysis, which did not include the geometry of the components and connectors.1

New software tools and high-powered desktop computers now make three-dimensional (3-D) analysis possible. All components on the populated board can be included in the analysis along with probe forces and placement of the push finger/supports. With the continued trend of squeezing more and more components on PCBs, this software can become part of standard fixture development to prevent damage during test.

Nature of the Problem

Standard vacuum and pneumatic fixtures can subject the PCB under test to damaging stress levels if the fixture is not constructed properly. For example, a test fixture with 3,000 8-oz spring contacts will push against the board with as much as 1,500 lb of force. Push fingers or vacuum pressure can place additional forces on the board.

This may sound like a huge amount of force, but it actually will not harm the PCB under test in any way as long as the forces are applied and counterbalanced properly. For that reason, BSA is an invaluable tool.

The BSA allows a simulation to be performed before the PCB is subjected to potentially damaging forces. Once the simulation is run, push fingers, board supports, and even probes can be repositioned to reduce flexing and lower stresses placed on a PCB. Typically, the BSA is rerun in an iterative process that successively betters the fixture design until the desired result is achieved.

The forces applied to the PCB by pneumatic and vacuum fixtures are quite different. For example, a vacuum fixture applies uniform pressure (the weight of the atmosphere) to one side of the PCB, which is counteracted by the force of the spring probes and board supports. The pneumatic fixture applies force to the PCB through push fingers strategically placed to counteract the force of the test probes. In either setup, an improper application can lead to damage.

Nature and Magnitude of the Stresses

As the test fixture is actuated, the forces begin to stress the board and the components mounted on it. The board will flex upward or downward depending on which applied force has the greater magnitude.

The components on the PCB also are subject to these stresses. Leaded devices have significant compliance through their leads and typically are unaffected by the board flexing. But surface-mounted components, since they adhere to the surface of the PCB, are subject to a disproportionate amount of stress. They, in effect, become stiffeners that resist the flexing, and the stresses then are multiplied by their rigid mounting and device geometry.

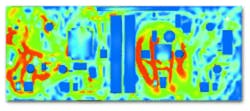

Figure 1 (below) depicts some of the reactive forces to which surface-mounted devices are subjected. In this example, components mounted on the top surface would be compressed by the board flexing while components on the reverse side would be stretched. The degree of flexing and the abruptness of the flexing must be controlled to protect surface-mounted devices.

Figure 1. Forces on the Components

Typical failures of these devices include broken or degraded solder joints and broken components which may lead to false test results. Unfortunately, a marginal solder joint may pass electrical test when it is forced into contact with the pad.2

Comparing 2-D and 3-D Stress Analyses

The stiffening effect of the components and connectors dramatically changes the magnitude and location of the stresses and deflections on the board. To demonstrate, 2-D and 3-D analyses of the same board were performed.

Generating the 3-D Analysis

Evolving computer-aided design (CAD) software technologies have enabled 3-D BSA to become more automated than 2-D. The 3-D BSA uses the board and component geometry directly from the board designer’s data using electrical CAD (ECAD)-to-mechanical CAD (MCAD) translation software. MCAD translation software currently supports 13 ECAD packages.

The 3-D finite element analysis (FEA) software runs within the MCAD software, providing complete associativity between the solid model and the analysis. This means that design changes in the solid model, such as adding or relocating board supports, automatically are reflected in the analysis model, allowing multiple design interactions to be analyzed quickly and accurately. Probe forces are applied in the FEA model via a custom-generated program, which uses the application-programming interface of the MCAD software.

Another benefit of the latest generation of FEA software is improved accuracy coupled with decreased processing time. Typical early 2-D models used relatively coarse mesh and took several hours to process. Today’s FEA software supports mesh sizes that are orders of magnitude smaller than the 2-D models while cutting processing time to typically less than 1 hour.

Added Benefits

Once the FEA has been completed, fixture fabrication files can be automatically generated using computer-aided manufacturing (CAM) software that also runs within the MCAD software. The software provides precise placement of board supports in the fixture top plate or pocket milling for component clearance in fixtures designed for the board to sit flush on the top plate.

The process involves creating a model of the fixture top plate. Features such as tooling holes and board-support mounting holes are located using an external reference to the board geometry. An external reference in the MCAD software indicates that a feature in one part depends on a feature in another part for its solution. If the referenced feature changes, the dependent feature also changes. This ensures that the tooling holes and board-support mounting locations in the top plate always mirror the board.

For fixtures designed for the PCB to sit flush on the top plate, the process is similar. The MCAD software offers a mold cavity tool that creates a negative image of the board in the top plate. Component offset clearances can be globally selected or tailored to individual components. Once the top-plate geometry has been established, the CAM software automatically extracts the machinable features from the top plate and generates a machine-code file for the milling/drilling machine.

Having CAD data in such detail also makes it possible to build finished fixtures without waiting for a PCB. The capability to build a simulated PCB from CAD data holds the promise of reduced time to market.

The same process is used for pocket milling the top plate. But in this case, molds of both the top and bottom images of the board as well as a blank representing the board itself are created. Then, the molds are used to make positive images of the board using hard gasket material. These images are adhered to the board blank, resulting in a very accurate representation of the populated board.

Summary

3-D BSA is a vital fixture development tool that provides a realistic view of the relative forces that will be placed on the PCB under test. It can help eliminate potential damage to the PCB and its components during production test.

A broken PCB can cost thousands of dollars and lost time. Based on the desktop computer processor power now available, the migration of PCB designs to 3-D CAD, and the need for improved quality, the means are there to make 3-D BSA a practical part of the fixture design process.

References

- St.Onge, G., “A Method to Control Board Flex,” EE-Evaluation Engineering, September 1989, pp. 14-18.

- Green, S., “Hidden Costs of Board Stress in Test,” Electronics Manufacture and Test, May 2000.

About the Author

Gary St.Onge is vice president of the Test Fixture Group at Everett Charles Technologies. He holds a master’s and a bachelor’s degree in mechanical engineering from Union College. Mr. St.Onge also is a licensed professional engineer in New York state and has received eight U.S. patents related to test fixturing. email: [email protected]

Tom Newhall is a product design engineer at Everett Charles Technologies. He has a bachelor’s degree in mechanical engineering from Clarkson University and 15 years of engineering experience with ECT and General Electric. email: [email protected]

Everett Charles Technologies, Test Fixture Division,

1 Fairchild Square, Clifton Park, NY 12065, 518-877-7042.

Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 2000 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

August 2000