NEBS were introduced to the compliance world by Bell Communications Research (Bellcore). Bellcore, now Telcordia Technologies, was an extension of the seven Regional Bell Operating Companies (RBOCs) following the divestiture of AT&T in 1984. The reason for these standards is simple: to make sure that our communications equipment remains functional at all costs.

The reliability rate of telecommunications equipment is expected to exceed 99.9%, which is stringent by any standards. NEBS, particularly GR-63 CORE and GR-1089 CORE, were created to address the issues of reliability of telecommunications equipment designed around a central office (CO) installation.

GR-63 CORE

GR-63 CORE Physical Protection deals with physical characteristics of the equipment. There are numerous tests involved in the compliance process for GR-63, some more severe than others.

The earthquake simulation is an example of a severe test. It simulates a 32-s time-history shock pulse created by Telcordia, with the shock response spectra (SRS) in the range of 5g at the base of the frame. The low-frequency portion of the time history produces displacements of approximately 10 in. peak-to-peak.

For the simulated earthquake, the unit under test (UUT) is mounted into a Zone 4 certified test frame, and the frame is configured to best duplicate the mass and stiffness of a fully loaded frame. Let’s face it, the need to occupy every square inch of a rack in a CO is common. The 32-s time-history shock pulse then is performed and the excitation of the framework measured at both the middle and top of the frame.

Displacement at the top of the frame is measured relative to the base in inches and must not exceed 3 in. zero to peak. The UUT must be functional both before and after the test, with an objective for the unit to function during test.

Another of the more severe tests is the fire-spread test. It determines how the UUT will react when a flame is introduced to the system, in hopes that the flames will be contained within the UUT. A circuit card is removed from the system, and a blank faceplate is placed over the empty slot. A hole approximately ¾² in diameter is drilled into the blank faceplate, and a 6-in. burner wand is inserted through that hole. The burner wand simulates a circuit card on fire.

The methane gas used for the test is controlled to a profile to run from 0.5 liters/min to 9.0 liters/min maximum, eventually extinguishing at the 5.5-min mark. Systems with fans are required to power only the fans, preferably off the backplane if that is the normal installation procedure. It is best to replicate the system’s fan characteristics as closely as possible to find the actual effects of the fans on the fire-spread test. There is a misconception that fans will induce the flames, when in actuality, the fans help dissipate heat pockets within the chassis.

Other tests include temperature/humidity and altitude (both functional), handling such as packaged and unpackaged drops, and transportation simulation on a vibration table.

Acoustic noise is measured using sound pressure (dBA) as the measurement factor to assess the noise being generated by the fan system. GR-63 calls for a level of 60 dBA for equipment installed in a CO lineup.

Heat release, or heat dissipation, is quickly becoming a matter of concern. With the increased board density and smaller and smaller systems, the output wattage of these telecommunications systems is becoming so high that the heating, ventilation, and air-conditioning systems in many current COs cannot handle the heat release. This issue is of particular concern, especially with the emergence of optical switches that can output some 3,000 to 6,000 W. Many COs actually place fans in the aisles to move the heat.

GR-1089 CORE

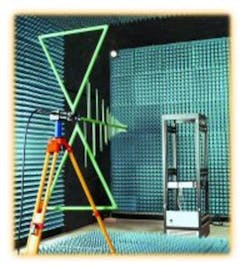

GR-1089 CORE Electromagnetic Compatibility and Electrical Safety deals with the electrical characteristics of the telecommunications equipment. One of the more prominent issues in the design of telecommunications equipment is the shielding methods used for emissions. Pre-scans can be helpful in finding the problem areas and assisting in resolving the overall system emissions issues.

GR-1089 is divided into four product types. Types 1 and 3 products have a direct connection to outside plant metallic tip and ring conductors. Type 1 is for CO installation, and Type 3 is for customer premises. Types 2 and 4 have no direct connection to the outside plant, with Type 2 being CO and Type 4 being customer premises.

The type will define if lightning surge is to be inter- or intrabuilding. This is important because the levels for interbuilding are much higher considering the unit could be affected by a direct strike to the telecom line, as opposed to intrabuilding, which has other equipment placed in line before the outside connection.

The AC power fault test is similar to the lightning surge since it deals with a surge to the telecom interface line, such as T1. Realizing that telephone lines are placed close to high-voltage power lines, the capability of the power lines to cross the phone lines is a real possibility. The AC power fault test simulates a surge from the crossing of these two lines and the effect of the lines crossing.

The AC power fault and lightning surge are divided into first-level and second-level criteria. First-level criteria state that the system must function normally after the stresses are applied. According to a second-level criterion, the equipment may stop functioning but must not become a fire, fragmentation, or electrical safety hazard.

Some of the more standard issues of testing involve electrostatic discharge (ESD), bonding, and grounding, which defines the integrated ground-plane and the isolated ground-plane configurations. Electrical safety addresses the personnel who work with the equipment, whether in normal service use or in repair of the equipment.

The steady-state power induction test is intended to ensure that the equipment will function in the presence of steady-state AC power that may be encountered in a local exchange carrier (LEC) network such as SBC or Verizon. DC potential difference characterizes the voltage difference that may occur between equipment locations, such as a CO and a remote location. The equipment under test must perform its regular function when there are differences in the DC potential.

Conclusion

The process for testing to Telcordia NEBS GR-63 CORE and GR-1089 CORE can be a long, drawn-out process. Considering the intense level of competition and the importance of time to market, you may want to provide up to three fully functional units for test to speed up the program. Even with three units, the process still takes up to 45 days from start to finish. But the testing assures us that the equipment being installed today will provide high reliability tomorrow.

About the Author

Don Bennett is the acting telecommunications test manager at Garwood Laboratories. As a member of the T1.8 Physical Protection and Design Committee, Mr. Bennett has been involved in telecommunications compliance testing for more than eight years. His work experience started at Bellcore and continued at Lucent Technologies Bell Labs Division and National Technical Systems. Garwood Laboratories, 7829 Industry Ave., Pico Rivera, CA 90660, 562-949-2727, e-mail: [email protected].

Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 2001 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

June 2001