When it’s time to purchase a new test instrument, even a hand-held digital multimeter (DMM), roll up your sleeves. There are so many models of the world’s most-used electronic test instrument on the market today that you’ll need a scorecard to compare them.

Millions of DMMs are sold every year to all sorts of buyers. Most are purchased for less than $100, but they can range up to $300 or more. The more expensive units are test tools for specialized uses or possibly more exotic instruments laden with advanced features for the serious professional.

In many ways, DMMs can turn test-and-measurement tricks. They also can provide a quick return on your investment. By adding a couple of accessories, specialized probes, and adapters, the functional possibilities are limitless.

The price for the specialized meter can be out of this world, too. When the additional cost of user training and the increased likelihood of errors are considered, the unit’s final price is higher still. This is a real issue if you just need to measure some simple parameters. Sure, the DMM isn’t as complex or expensive as an oscilloscope, logic analyzer, or microwave signal generator, but the same purchasing decision applies—don’t buy more than you need.

Seven questions come to mind when choosing a DMM. Short of conducting an in-depth research project that could take weeks, there are crucial factors that you need to consider. Whatever the instrument, the answers to these questions will affect your ultimate choice and purchase price as well as your eventual satisfaction.

- What is the hidden cost of buying too much instrument?

- For what purpose will the DMM be used?

- How do you handle your instruments?

- What is your work style?

- Is this purchase a long-term or short-term investment?

- Do you need a compete kit, or will you buy accessories separately?

- What do you need in after-purchase service and warranties?

What Is the Hidden Cost of Buying Too Much DMM?

With a hand-held DMM, just like a spectrum analyzer or computer, it’s possible to spend plenty and get a multifunction, multitask, and multicomplicated unit with all the fancy bells and whistles. Be aware, however, that as the DMM options and features mount, so do the potential problems associated with the unit’s complexity.

For instance, a meter destined for datalogging or one with an RS-232 interface may be the top of the line. However, if you only need to measure AC/DC current, AC/DC voltage, and ohms, you can get along fine with a much simpler instrument.

When you use a complicated or unfamiliar DMM, there are significant risks of accidentally conducting the wrong test, possibly damaging the unit under test, or even injuring yourself. Recent industry research indicates that some consumers actually prefer the simplicity and safety of a basic DMM.

There also is the cost of learning to use the extra features correctly and the proper measurement protocols that assure precise measurements. Learning to convert 4 to 20-mA current loop readings into percentages requires training and skill, but most users never will need this capability. It’s also possible that when measuring milliamps you could be misled into thinking that the readings represent a percentage of the full-scale current.

What is the realistic resolution to look for in the instrument? More than three digits on the display is merely noise according to a high-level industry engineer familiar with the dynamics of user confusion.

By selecting a quality, basic meter that is quite straightforward in its feature set, you will find it easy to use and read. This saves money and avoids potential problems while decreasing your necessary learning curve.

Consider the requirement to measure VAC and VDC. A simple three-function meter (adding ohms and continuity functions) is about as simple to understand and use as it gets. If that’s all the functional capability you really need, why purchase more?

For What Purpose Will the DMM Be Used?

Hundreds of DMMs on store shelves have a similar look and feel. Without asking the intended purpose of the meter, you could end up with a meter with the wrong features or improper ranges for the tasks at hand. Determine early on what there is to do; then frame your search along the lines of specific needs.

Will the measurement of voltage, current, ohms, or a combination of all three be needed? Is frequency, temperature, or capacitance necessary, or will these functions ever be used? What ranges are needed?

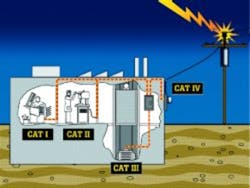

Some popular DMM models are designed for low-voltage, low-energy electronics troubleshooting (Categories I and II) while others are right for low voltage with high or low current as found in home and automotive applications (Category I to III). Still others are offered for outdoor high-voltage use (Category IV) such as found in pumps or utility-service extensions. See the sidebar for a discussion of overvoltage installation Categories I, II, III, and IV.

Make certain your new meter fulfills the basic electrical requirements you need. Select one with the right safety, including overvoltage protection, for your application.

In What Environment Will the Test Tool Be Used?

Do you work in a shop or in the field? Will your meter need to be heavy duty, waterproof, and rugged? Or will you mainly perform delicate, precise measurements indoors? The answer may direct you to a specific product.

Will you be working in daylight or inside dark electrical closets? Backlit LCDs are a necessity where light and visibility are low. You may be in a well-lighted room but measuring under a desk or inside a large cabinet. These are places where a backlit display really is handy.

What about size and shape? Will the DMM fit your tool kit? Will you need to work in a tight space or overhead where a small, probe-style penmeter would be appropriate?

Many electricians and gaffers in Hollywood movie studios prefer this type of meter because they are light and fit easily into a pocket. The integrated probe point of a penmeter permits easier measurement operation in difficult-to-reach situations and where there’s no place to hang or rest the meter.

With a penmeter, you never need to wonder how to support the meter. One hand holds the ground probe in position, leaving the other hand to move the meter/probe among test points as required.

What Is Your Work Style?

Will your meter stay indoors, or will you carry it outdoors on a tool belt? Or will you keep it mainly on your workbench? Some DMM models incorporate prop-up stands; others feature integrated holsters resilient enough for the most demanding on-the-job situations. If you use your meter in a tough environment, the money spent for a meter carrying case or holster to protect your investment is worth it.

Is This a Long-Term or Short-Term Investment?

Will your meter perform as a primary tool or as a backup to another more high-end meter? Many workers demand the confidence of having a backup DMM so they always are prepared. Others have only occasional need for their DMM. Either way, a mid-priced, multifunction DMM fits the bill nicely.

Do You Need a Complete Kit?

Fortunately, many suppliers offer complete ranges of test leads, probes, and thermocouples. Several companies also have task-related accessory kits that supply everything you’ll need to undertake specific measurements.

At the Boeing Commercial Airplane plant in Everett, WA, for example, the production team regularly carries a deluxe test lead kit as part of the standard work tools. The kit typically would have test spade lugs for use when making measurements in a permanent test setup. Spring-loaded crimp tips for making low-voltage measurements also are useful when troubleshooting avionics aboard a Boeing 777 airplane.

Another useful test lead is the common alligator clip that facilitates hands-free measurement tasks. Also, small test-tip extenders can help reach recessed nodes in aircraft entertainment systems.

What Are the Factors of After-Purchase Service and Warranties?

With many meters and test tools being manufactured in other countries, the basic meter warranty is of primary consideration. Who will repair it? Where will it be sent for warranty work? Or, does the manufacturer offer an on-the-spot replacement program that saves time, money, and hassle? The answers could save a great deal of angst when repair or technical support is needed.

Carefully reading a meter’s specifications before you buy can make your next test tool purchase a simple task rather than a frustrating exercise. Buy the right meter for your needs.

About the Author

Terry LaBrue is the marcom associate at Wavetek Meterman Test Tools. He received a B.A. from California State University and has more than 20 years of experience in writing and editing electronics and high-tech communications.

Wavetek Meterman, Technical Information, P.O. Box 9090, Everett, WA 98206, 877-596-2680

For More Information

Wavetek Meterman Technical Materials

www.rsleads.com/208ee-178

Understanding Safety Categories

The real issue for test-equipment circuit protection is not just the maximum steady-state voltage range but a combination of both steady-state and transient overvoltage withstand capacity. Transient protection is vital.

When transients ride on high-energy circuits, they tend to be more dangerous because these circuits can deliver large currents. If a transient causes an arc-over, the high current can sustain the arc, producing a plasma breakdown or explosion that occurs when the surrounding air becomes ionized and conductive. The result is an arc blast, a disastrous event that causes more electrical injuries every year than the better-known hazard of electric shock.

The single most important concept to understand about the new standard is the Overvoltage Installation Category. The new standard defines Categories (CAT) I, II, III, and IV. A higher category number refers to an electrical environment with higher power available and higher energy transients. Within a category, a higher voltage rating denotes a higher transient withstand rating.

Ranging from CAT I protected low-energy circuits to CAT IV installations with high-powered lines exposed to outdoor environments, the rigorous IEC international standards are written to keep you safe. Meters designed to the new standards are more capable of withstanding the hazards caused by transients and other dangers in today’s electrical systems.

Category I—typically covers electronic equipment:

- Protected electronic equipment.

- Equipment connected to (source) circuits where the transient overvoltages are limited to an appropriately low level.

- Any high-voltage, low-energy source derived from a high-winding resistance transformer, such as the high-voltage section of a copier.

Category II—for single-phase receptacle-connected loads:

- Appliances, portable tools, and other household loads.

- Outlet and long branch circuits.

- Outlets at more than 10 meters from a CAT III source.

- Outlets at more than 20 meters from a CAT IV source.

Category III—three-phase distribution, including single-phase commercial lighting:

- Equipment in fixed installations, such as switchgear and polyphase motors.

- Bus and feeders in industrial plants.

- Feeders and short branch circuits and distribution panel devices.

- Lighting systems in larger buildings.

- Appliance outlets with short connections to the service entrance.

Category IV—three-phase at a utility connection, any outdoor conductors:

- Origin of installations, such as where a low-voltage connection is made to the utility power.

- Electricity meters, primary overcurrent-protection equipment.

- Outside and service entrance, a service drop from a pole to a building, run between the meter and the electrical panel.

- Overhead line to a detached building, underground line to a well pump.

CAT II conditions are most prevalent, but that shouldn’t lull those testing electric lines and sources into complacency. As soon as you move from inside a house or garage outside or into an industrial setting, chances are you’re dealing with CAT III or CAT IV. For large industrial motors, you’re in CAT IV territory, and extra precautions should be taken.

Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 2002 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

August 2002