If there�s one electronic gadget that most of us own or at least have some familiarity with, it�s the cell phone. Almost like the message proclaimed in an ad by a major credit card company, �You wouldn�t leave home without it.�

Today�s cell phones are complex electronic systems expected to work flawlessly in just about any environment. Most users don�t have a clue about some of the challenges designers have to overcome to deliver a versatile and reliable product. Because so many diverse technologies�analog, digital, power, and RF�are crammed in such a small space, eliminating or, at least, minimizing circuit interference is at the top of the list of product requirements. Here�s how one EMI problem was solved in a flip-type phone.

This example was related by Mike Evans, director of applications at California Micro Devices. The EMI problem was caused by the wiring that carries the digital signals between the baseband microprocessor on the bottom flip of the phone to the LCD module and the camera on the top flip. This wiring is a few centimeters long and comprises between 20 and 60 data lines, making an excellent antenna.

Unwanted carrier frequency signals picked up by the data lines on the base flip and EMI generated from the data signals during transition time were present on the wiring. With both sources of EMI, the phone most likely would fail EMI certification. Also, there is a potential ESD problem at the hinge between the flips so the data lines must be able to withstand ESD events as well.

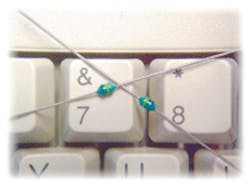

The solution was to place EMI filters with ESD protection on the PCB nearest the hinge. Because RC-type filters can eliminate the noise and are available in chip-scale packaging, the requirements for small size and low cost were met.

Each filter provides 15 kV of ESD protection for each of the eight data lines, all in a 4 mm � 1.4 mm package. Because of the low parasitic inductance and low equivalent series resistance of the capacitors in each filter, attenuation of 35 dB to 40 dB can be achieved from 800 MHz to 6 GHz. Most flip phones now incorporate this type of filter.

Another example, as reported by Rick Johnson at R & F Products, a Laird Technologies Co., shows how microwave absorbers were used to suppress EMI in a high-speed switching network. High-frequency energy was leaking out where fiber-optic transceivers were installed in the front of the switching unit.

The front panel consisted of 32 transceiver plug-in modules with two LEDs next to each module. Initial shielding already had been put in place but could not contain the >6-GHz leakage from around the transceivers. The energy apparently was manifesting itself as surface currents along the front of the equipment.

By using a die-cut magnetic absorber bonded with pressure-sensitive adhesive to the front of the unit, the leakage was effectively eliminated. The absorber was 0 .060� thick, loaded with magnetic filler, and optimized for the frequency range of 6 GHz to 18 GHz. The strip of elastomeric magnetic absorber was die cut to fit over all of the modules and LEDs.

Trends

For EMI suppression components, small size coupled with improved performance are driving the development of new products. Manufacturers are continually pressured to cram more functionality into smaller packages.

As noted by Dave Armitage, components engineering manager at Schaffner EMC, ��there is a clear move from the single EMC component toward a total solution. Wherever possible, customers like to have one solution covering harmonics, power quality, and EMC from one supplier. Of course, it goes without saying that lower cost of goods tops the list of requirements for customers.�

EMC Products

To help you find the right EMC solution for your application, a collection of products is presented, from absorbers to transient suppressors and active EMI filters to subminiature chokes. Be sure to access the rsleads link following each product for more information from the manufacturer.

AVX,

www.rsleads.com/408ee-188

FerriShield,

www.rsleads.com/408ee-189

J.W. Miller,

ww.rsleads.com/408ee-190

EMC Test and Design Consulting,

www.rsleads.com/408ee-185

The Absorbing Wall Module can be used in a shielded room to absorb interfering signals to help reduce moding problems. The module eliminates moding hot spots and resonances while providing good wide-angle performance. The RF specification of a 2� � 8� panel with a 12� thick absorber at 1 GHz is 32 dB and 41 dB for a 4� � 8� panel with 36� thick absorber. At 10 GHz, the performance for the 2� � 4� and the 4� � 8� panels is 50 dB. The modules can be ordered with or without 24-gauge sheet-metal backing.

Advanced ElectroMagnetics,

www.rsleads.com/408ee-186

OPHIR RF,

www.rsleads.com/408ee-193

The BNX016-01 Series of leaded filters is designed to provide noise suppression in DC power supplies. Rated at 25 VDC and

15 A, the LC filter has an insertion loss of 40 dB minimum over the frequency range of 100 kHz to 1 GHz. The 11 mm � 12 mm � 12 mm part has an operating temperature of -40�C to 125�C.

Murata Electronics,

www.rsleads.com/408ee-191

AR Worldwide,

www.rsleads.com/408ee-187

The 4306 Series Press-In EMI Filters have a minimum no-load insertion loss of 5 dB at 1 GHz and 20 dB at 10 GHz for the 4306-000 and 40 dB at 1 GHZ and 50 dB at 10 GHz for the 4306-002. The capacitance value for the 4306-000 is 10 pF and 2,700 pF for the 4306-002. The operating temperature ranges from -55�C to 125�C. The DC working voltage at 125� is 200 V for the 4306-000 and 100 V for the 4306-002.

Tusonix,

www.rsleads.com/408ee-194

Tech-Etch,

www.rsleads.com/408ee-199

Schurter,

www.rsleads.com/408ee-201

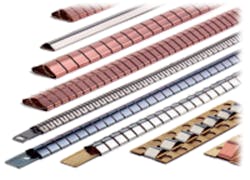

Designed for applications requiring environmental sealing as well as EMI shielding, the ElectroSeal D Strips provide as much as 120 dB of shielding effectiveness for a 10-GHz plane wave (when measured to MIL-STD-285) over the temperature range of -65�C to 200�C. Available in molded or extruded shapes or in sheet stock, the gaskets can be compounded with a variety of conductive filler materials. Solid cross sections or low-deflection hollow core cross sections are manufactured in lengths up to 100�.

Laird Technologies,

www.rsleads.com/408ee-196

The ACARA family of EMI filtered power connectors is rated at 65 A or 100 A at 50�C. The connectors are designed to provide EMI suppression to 10 GHz and available in a variety of capacitance values. The current-carrying conductor of the filter is connected to one terminal of the capacitor, and the other end of the capacitor is connected to ground through the connector�s metal housing. Unwanted RF currents will be shunted to ground.

Schaffner EMC,

www.rsleads.com/408ee-198

August 2004