Combining motion and machine vision expands inspection equipment capabilities.

Motion control and machine vision are used throughout the semiconductor manufacturing process, from monitoring the diameter of ingots as they are being formed from a crystal seed to aligning a die lead frame prior to wire bonding. In nearly every step of the process, motion and vision can be found working together to align, inspect, measure, and identify wafers and die so the various pieces of equipment can do their tasks.

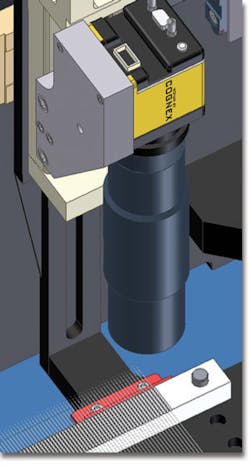

Point Technologies, a supplier of precision electrochemical pointing and micromachining services and products for small-diameter wire and tubing to the semiconductor, medical, and biotech communities, recently has applied motion and vision to a new area in the semiconductor industry: probe needle inspection (Figure 1). This new approach replaces a slow, labor-intensive, and error-prone method that required extensive operator training.

Eyeing the Needle

Semiconductor manufacturers rely on probe needles to test integrated circuits (ICs) while still part of a complete wafer to ensure that only the functional ones are packaged for final use. A probe needle is a straight, small-diameter metal wire with one end that tapers down into a sharp point. It establishes an electrical connection between tester and IC by contacting the metal bond pads on the wafer.

Generally, hundreds or thousands of probe needles are assembled into an array on a probe card tailored to interface between the specific type of IC being tested and the wafer prober. During testing, precise needle geometry is essential to ensure test-data reliability and consistency for several reasons.

First, when the wafer being tested contacts the probe card, the needles flex, causing the tips to slide across the metal pads. Consequently, probe-tip diameter is a critical dimension that determines the area of the pad that is scrubbed.

Next, the needle�s diameter and taper shape determine how much it will flex and the amount of force with which it touches down on the wafer. This is called the balance contact force, a critical contact pressure specification set by manufacturers that affects probe-card life and how well the probe tip will break through a thin layer of aluminum oxide on the metal bond pads.

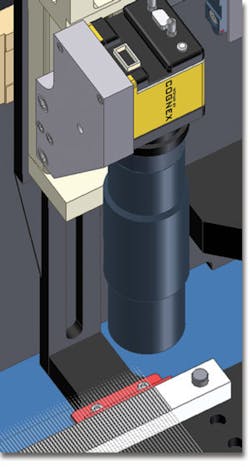

Finally, the probe tips must be accurately bent before assembling the probes on the probe card; this requires precise and careful work. Most probe-card manufacturers use reference diameter to determine where to bend the probe (Figure 2). If probe geometry is inconsistent, the reference diameter, bend angle, tip diameter, and tip length will be inconsistent. Any of these problems can cause probe misalignment and result in poor test-data consistency.

In the past, Point Technologies relied on a combination of manual video inspection systems and optical comparators to provide probe-card manufacturers with needles that met stringent requirements. However, as IC production volumes rose and demand for probe needles increased, this process was far too labor-intensive. Because needle inspection accounted for a significant proportion of the total manufacturing time, it was a prime candidate for automation.

Setting Sights on Automation

In late 2003, Point Technologies initiated an investigation of options for improving the needle inspection process. Commercially available equipment that could do the job was much too cumbersome, slow, and expensive to offer a viable solution, so the team decided to design a system to better meet its needs.

The primary design goals were to increase measurement throughput, accuracy, and repeatability while reducing inspection time. The system also would automatically document all measurements onto a shared server, minimize operator training, and maximize operator comfort. Finally, it would automatically plot the measurement data on a graph for comparison to customer specifications and provide statistical analysis for process improvements.

The engineering team set out to integrate motion control and machine vision. Upfront work was done to evaluate the feasibility of using a machine vision system to improve the measurement efficiency and still get measurements repeatable within 0.00002 inches.

The team started with an In-Sight� Vision Sensor from Cognex because it is easy to learn and comes with user software. The sensor consists of a DSP-based vision processing unit, a high-speed digital camera, onboard light control, and built-in discrete I/O. It also provides a standard VGA output for real-time display, built-in Ethernet communications, and an onboard serial port.

Without attending any formal training classes, it took approximately 30 hours to set up the inspection routine. In-Sight was a good validation tool; however, it wasn�t the right product for the final application.

Instead, the design team chose a Cognex VisionPro� PC-Based Vision System because it offered higher performance and provided more seamless integration with the motion-control system. Moving to the VisionPro platform took a lot more time to learn and required a couple of weeks of help from a Cognex Certified Vision Integrator (CVI). The CVI was instrumental in developing the vision code for the original system, a decision that also proved to be cost-effective since the code was used for subsequent systems.

The PC-based vision system uses a Cognex MVS-8100D Series Frame Grabber inside a basic Dell PC and a high-resolution (1,280 � 1,024) Cognex CDC-200 Digital Camera. One of the most challenging parts of any machine vision application is selecting the image formation system to produce a good picture. After some lighting and optics experimentation, the team implemented a high-magnification telecentric lens to eliminate optical distortions and a 2 � 2 inch diffuse LED backlight to provide suitable images with the necessary resolution.

Vision Meets Motion

The motion-control part of the system is essentially a tabletop, Cartesian robot with stepper motors to drive three axes of motion. One axis moves the loading table into and out of the inspection area. The other two axes control vertical and horizontal camera movement. The motion system combines assorted components such as a three-axis motion controller, precision linear slides, leadscrews, and stepper motors.

Logic and control are managed with Visual Basic, which allows stepper motors to move the camera and position the needles. Vision-guided motion applications such as this require a very fast vision system that will synchronize image capture, analysis, and measurement with the motion required to find and focus the needle and move from needle to needle. The team integrated the vision, motion, operator interface, network communications, and database using MicroSoft Visual Basic 6.0 on the PC into the PointScan Automated Needle Inspection System (Figure 3).

In all, the team went from concept to working system in about six months. Since late 2004, five systems have been built and are being used in production.

Although there were some challenges, the design team�s previous experience building multi-axis automation systems made the mechanical design pretty straightforward. For example, due to the very small size of the probe needles and the high magnification of the vision system, special care was taken to eliminate sources of vibration in the machine design by using vibration dampers.

Another challenge arose when considering camera resolution, optics, and working distance to achieve the desired field of view (FOV). The entire length of a part being measured didn�t fit into the FOV, so the part had to be moved a fixed distance under the camera to complete the taper length measurement. This complicated the application because it required combining the information from more than one image.

Integrating vision and motion also requires that engineers carefully calibrate the vision system with the motion system. If there�s optical distortion from the lens or perspective changes in the camera mounting angle, this involves more than determining a scaling factor that relates pixels to a measured dimension. The vision system tool suite includes special algorithms to correct for these errors.

Lights, Camera, Inspection

Prior to inspection, 200 blank straightened wires are loaded into a transferable fixture or block and then tapered in a proprietary Electro-Chemical Pointing (ECPTM) process. The needles are inspected in process and after completion. The specifications for every job are stored in a shared database, so after setting the fixture down on the loading table, the operator simply starts the inspection.

The loading table automatically indexes the probe needles into the inspection area. The camera then moves over the top of the needles from the side. When its FOV intersects the first needle, the table backs up until the point is located. Tight coupling of the vision with the motion allows the two systems to communicate and then center the point in the FOV.

To optimize measurement accuracy, repeatability, and reproducibility, PointScan includes an automatic focus routine. During this step, the vision system communicates with the motion system as it moves the camera up and down to focus on the needle. Once focused, the vision system acquires and analyzes the image and makes the appropriate measurements with the required accuracy. The data is automatically recorded, and the camera jogs to the next needle to be measured.

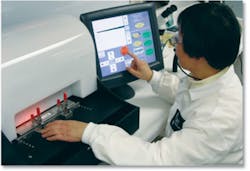

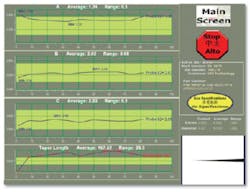

As measurements are recorded, the data is plotted automatically on the screen so the operator can see if they are within specification (Figure 4). At the end of the inspection, the system automatically unloads the needles, and the pins are accepted or rejected.

If the parts are rejected, the operator must rework or make new parts. The inspection data can be used to adjust the process. Additionally, inspection data is archived on parts that have successfully passed the inspection process. At the end of the job, the system generates an inspection report to accompany each shipment that includes all of the data for the measured parts and compares it with customer specifications.

Intelligent Inspection

Machine vision has enabled the design team to create an inspection system where a computer does all of the inspection and most of the data analysis. Tests indicate more than a ten-fold reduction in inspection time.

In the past, it took a person about 20 minutes to measure 12 needles and record the data on paper. PointScan measures 12 needles in less than 2 minutes, records the data, and automatically graphs the data for the operator.

Machine vision has proven invaluable for accurately gauging very small parts and providing qualitative results that can be used to track parts and productivity and help troubleshoot inefficiencies in the process. As a result, Point Technologies sees machine vision and motion control as key for the future of manufacturing. Integrating vision with motion is not as difficult as some would have you believe. Although it does take time, money, and expertise, if done right, even the most challenging applications can pay off.

About the Authors

Dave Senders is a manufacturing design engineer at Point Technologies specializing in machine and product designs for the semiconductor, medical, and biotech industries. Mr. Senders holds a degree in mechanical engineering from the University of Colorado. Point Technologies, 6859 N. Foothill Hwy., Boulder, CO 80302, 800-557-7059, e-mail: [email protected]

Steve Neely works in Berlin, Germany, as the director of engineering in Europe for Point Technologies. Since 2001, Mr. Neely has held positions in production/operation management and was an engineering manager focusing on product development and process development. He received a mechanical engineering degree from the University of Colorado. e-mail: [email protected]

John Lewis is a writer and public relations specialist at Cognex. Formerly a technical editor for an engineering magazine, he has nine years experience writing about factory automation, machine vision, and other technology topics. Cognex, 1 Vision Dr., Natick, MA 01760, 508-650-3000, e-mail: [email protected]

FOR MORE INFORMATION

on Cognex machine vision systems

www.rsleads.com/505ee-179

May 2005