The power of LAN-based communications interfaces has transformed the way we approach everyday activities. Whether checking in for a flight or watching a movie, applications abound to save time and simplify transactions. Many of the time-saving utilities once viewed as consumer-based gimmicks, such as accessing a wide range of information on your hand-held, now are finding their way into business transactions and gaining much wider acceptance.

To extend the benefits offered to customers across a wide range of application spaces from functional test to distributed data acquisition, embedded Web-based tools have been identified as key elements. LAN Extensions for Instrumentation (LXI) is the ideal platform for these Web-based tools, which provide features such as embedded Web interfaces, in-place calibration, simplified debug and startup, deterministic over-the-wire synchronization, remote data access, and comprehensive hand-held access.

Embedded Web Interfaces

Embedded Web interfaces extend the utility of the host instrument by providing measurement and control capabilities independent of any other programming interface. However, the concept of an embedded Web interface should not be confused with earlier incarnations based on applications resident on external computers connected via some interface such as IEEE 488. This type of implementation required instrument drivers resident on the host computer to communicate with the device. Numerous interoperability issues resulted from this approach including compatibility and restrictions with operating systems, device driver revisions, and instrumentation firmware levels.

An embedded Web-based approach eliminates all of these issues thanks to agnostic interfaces compliant with standard Web browsers. Additionally, each instrument is configured to launch and manage all aspects of the Web interface, eliminating the need for any external computer software configuration or interaction. Graphic representation, control interfaces, and data management are performed by the instrument’s Web server, resulting in an extremely high degree of computer and operating system independence.

Incorporating this functionality does add a certain degree of complexity to the instrument but provides significant advantages to the user beyond agnostic operation. Many of the delays that engineers encounter during startup, software development, and validation also can be minimized using a number of these embedded capabilities.

Debug and Startup

System startup and debug activities can be time-consuming under the best circumstances, and these challenges can increase in complexity when high channel-count, distributed applications are involved. Embedded instrumentation interfaces simplify this process by providing a number of the key benefits including:

• Instrument discovery and identification.

• Immediate out-of-the-box operation.

• Elimination of variables such as third-party software.

• Utilities such as the LXI Event Log that permits observation of the device in action.

Instrument discovery and identification are nearly transparent; techniques common in home computer and entertainment markets for identification of printers and other network resources have been leveraged extensively. Initiating communications with the instrument is as simple as applying power and connecting an Ethernet cable. The embedded interface is designed for compatibility with the most widely used and supported discovery mechanisms to reduce initial connectivity and communications issues.

Once the instrument has been identified, the embedded Web interface can be launched by typing the IP address, hostname, or MDNS name displayed in the discovery window into a Web browser. This entire process can occur in less than a minute. The result is immediate out-of-the-box operation. The built-in soft front panel then can be used to establish and verify communications with the instrument, perform setup, and initiate measurements. Eliminating external software interfaces and drivers provides a high degree of isolation as well as an important reference point for debugging and software validation activities.

A common validation approach leverages the embedded interface to configure and acquire measurements and then compares these results with those obtained using the higher-level application program. For example, it is possible to monitor the instrument during operation to verify that the proper configurations are sent and measurements are being taken.

Furthermore, transducer operation and cabling installation can be quickly verified using this approach. This can be performed with an inexpensive laptop, simplifying the entire process and reducing costs.

Calibration

Another time-consuming and potentially expensive aspect addressed by embedded Web interfaces is the entire calibration process. Calibration not only includes costs directly associated with the instrumentation but also those linked to reduced facility availability and utilization.

Data integrity and validity are essential for nearly all applications, and a key aspect of this is instrument calibration to traceable verification standards. Specifically, a traceable source is used by the instrument undergoing calibration to adjust and verify the quality of measurement. This often has been viewed as a painful but necessary process involving system disassembly and downtime.

Typically, the process entails disassembling field terminations and sending each instrument to its respective vendor’s factory for calibration. Some costly alternatives include ordering spare instruments for each test station, hiring an outside calibration service, or constructing an in-house calibration laboratory. Reducing these costs and alleviating the downtime associated with the calibration process ultimately benefit all test and measurement applications.

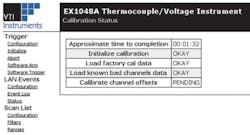

Some embedded Web interfaces, such as those incorporated in VTI’s integrated data acquisition signal-conditioning systems, are designed to perform the entire calibration process automatically—in place. This is accomplished by combining the embedded calibration functions, along with onboard precision voltage references, in the instrument. Specifically, the calibration process is programmed directly into the instrument’s firmware and controlled via the embedded interface, allowing you to execute a complete calibration in minutes.

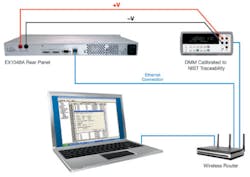

The fully integrated embedded Web interface streamlines the calibration process, making it more convenient and cost-effective, in-place, and without disconnecting field connections. To perform a complete NIST-traceable calibration, only a Web browser and precision voltmeter are required. The voltmeter is connected to the instrument using banana jacks, and control of the automatic factory calibration is initiated through a standard Web browser (Figure 1).

The instrument’s embedded interface can be configured to recognize and communicate with several different voltmeters. This is required to measure the on-board precision voltage source (Figure 2). The internal reference voltage then is routed through each independent signal path and utilized to perform internal adjustments. The calibration coefficients then are stored in nonvolatile memory.

When compared to other methods, this requires little user interaction and no calibration software development. The simplified equipment setup enables the process to be executed almost anywhere. For example, instead of sending the instrument to the metrology lab, test engineers can send the metrology lab to the instrument.

Also, prior to each data acquisition sequence, the device can execute a self-calibration procedure directly from the software or the Web browser interface. The precision on-board voltage source not only enables NIST-traceable calibration, but it also extends the calibration capabilities to runtime.

Before any measurement is taken, users can initiate a self-calibration sequence that routes the precision source back through the actual measurement path. Whenever the device undergoes changes in its surrounding thermal environment such as from a cool morning to a hot afternoon, this process can be executed in only a few minutes to ensure precise measurements.

Synchronization

Measurement integrity is clearly a critical requirement transformed with embedded tools; however, data also must be synchronized and time correlated especially when many devices are distributed around a test article or throughout a facility. Both LXI Class A and Class B instrumentation have the capability to uniquely resolve these issues via the application of IEEE 1588 timestamps to data and event notifications. IEEE 1588 timestamps are controlled by a local LAN-based master clock, which can synchronize instruments to within nanoseconds of each other.

The LXI Standard identifies two approaches for synchronization and triggering, and each was developed to address different application requirements:

• Class C: Network Time Protocol by default.

• Class B: IEEE 1588 Precision Time Protocol (PTP) Synchronization.

• Class A: Trigger Bus Hardware Trigger Interface.

LAN synchronization incorporating PTP highlights a fundamental advantage of LXI Class B devices that is ideal for distributed measurements. This completely over-the-wire approach provides a mechanism to synchronize multiple instruments separated by thousands of meters or across the globe.

PTP defines a precision clock synchronization protocol for networked measurement and control systems. The protocol is designed to enable the synchronization of systems that include clocks of different precision, resolution, and stability. Microsecond accuracy can be achieved with minimal network and local clock computing resources and with little administrative attention from the user.

PTP provides multiple device synchronization while eliminating the need for external cabling between devices. This approach is less accurate than hardware triggering; however, dedicated IEEE 1588 hardware assist can provide synchronization times in the nanosecond range which may be suitable for many data acquisition applications. Several parameters can be configured through the embedded interface including local time, master/slave designation, time source, and returning time status.

While PTP provides advances in over-the-wire synchronization, there always will be instances where additional accuracy is required. As a result, the LXI standard defines a high-performance trigger interface referred to as the LXI Trigger Bus. The LXI Trigger Bus, required in LXI Class A devices, provides traditional trigger distribution for both triggering and clock signal distribution.

Deterministic trigger generation and propagation among multiple devices are accomplished with an eight-channel, multipoint low-voltage differential signal (LVDS) interface. This architecture permits individual lines to be configured as a source or receiver and supports external, time-based, or software-generated triggering as well as clock distribution. Common topologies are supported including star, daisy-chain, and hybrid configurations providing the flexibility to distribute the trigger lines as dictated by the application requirements. Various features of the Trigger Bus are Web configurable and include source selection, manual control, wired-OR, and the capability to enable and invert signal levels (Figure 3).

Embedded data synchronization overcomes major hurdles essential for many data acquisition applications. Other aspects such as data management and security are easily addressed with built-in capabilities and well-established industry practices.

Data Transfer and Security

TCP/IP was chosen as the primary communications protocol for LXI-based instrumentation because of its robust nature and the capability to provide reliable data transfer with built-in error detection and correction capabilities. There are, however, well-documented first-byte latency delays that must be understood during system design to ensure performance levels are achieved.

A feature of VTI’s devices is autonomous data streaming to host devices, maximizing the throughput capabilities of Ethernet and effectively excluding first byte latency concerns. Once a test sequence is initiated, the embedded interface automatically buffers and transmits blocks of data. This eliminates the need for loop polling and individual requests for each block. The streaming interface maximizes the data throughput and bandwidth capabilities of Ethernet while minimizing data process overhead by the host computer.

Network security concerns can be easily addressed by using a dedicated test network. This is an inexpensive approach and provides the necessary isolation between corporate-wide network traffic and the test system. System synchronization and throughput also can be optimized with this approach, providing the highest degree of performance. Additionally, with little effort, the test system subnet can be interfaced to the rest of the corporation or the World Wide Web with a high degree of isolation.

The low cost and ease of use of today’s routers and hubs simplify the task of establishing a dedicated network, and this is apparent by the number of wired and wireless networks being installed in private homes. Standard Category-5e (CAT-5e) or -6 (CAT-6) cable is easy to route throughout test bays and around test articles, inexpensive to use, and available from many commercial sources.

Isolated instrumentation networks also eliminate many of the logistical issues that may arise when trying to conform to corporate network requirements. Security concerns can be addressed by not allowing physical access to outside network connections by installing a second Ethernet card, implementing a virtual private network, or physically disconnecting the network cable.

Hand-Held Wireless Access

There are, however, other issues that must be considered, specifically when you envision data access through wireless devices. Immediate access to information, regardless of time or location, is expected whether for business or personal use. Embedded Web interfaces simplify the task

of accessing and displaying information, and the popularity of this approach has exploded for several reasons:

• Conformance to industry standard Web display standards.

• Platform and operating system independence.

• Optimization/improvements of hand-held displays technology.

• Speed and accessibility of wireless networks.

Data can be accessed at any time and from any place by typing in the instrument’s TCP/IP address.

Alarm conditions can be evaluated quickly without physically traveling onsite and events immediately evaluated by different team members located across the country or around the globe. Concerns regarding unauthorized control or modification to the instrumentation’s configuration are addressed with features such as password-protected device lock-out, which permits read-only data access.

Summary

Embedded Web interfaces extend the utility of general-purpose Ethernet-based instrumentation interfaces thanks to well-defined features identified in the LXI standard. These additional benefits provide you with time- and money-saving advantages out-of-the-box and include reduced setup time, simplified debugging, quicker time to test, in-place NIST calibration, improved accuracies with run-time self-calibration, and wireless data access. This latest generation of instrumentation is revolutionizing the way engineers view traditional test challenges and defining the next standard in performance.

About the Author

Jon N. Semancik is the corporate marketing and business development manager at VTI Instruments. He has a B.S.E.E. from Fenn College of Engineering and an M.B.A. from the Weatherhead School of Management, Case Western Reserve University. Mr. Semancik is a U.S. Navy veteran and has held engineering and project management positions on numerous programs in both the military and the commercial sector. He joined VTI in 2002, where he previously was a product support engineer and a region sales manager. Mr. Semancik also is on the board of directors for the LXI Consortium. VTI Instruments, 949-955-1894, e-mail: [email protected]