EMC gaskets are available with combinations of properties to address virtually any application. Metal finger stock made from beryllium-copper (BeCu) or stainless steel (Figure 1) is a very effective, proven type of gasket but does not provide a seal against dust or moisture. Because each finger moves independently to make electrical contact, the effective gap length is very short, ensuring good high-frequency performance. Gaskets based on elastomers, either filled with conductive particles or covered with conductive material, are made in many profiles and can be good solutions, especially if a dust and moisture seal also is required.

Courtesy of Parker Chomerics

Finger stock

In a typical enclosure door application, mechanical as well as electrical characteristics must be considered. BeCu alloy 25 commonly is used for finger stock because it is the strongest copper alloy, it retains about 22% to 28% of the conductivity of pure copper, and it has excellent shielding performance. Chemically, alloy 25 consists of copper with between 1.8% to 2.0% of beryllium and a minimum of 0.2% of nickel and cobalt but no more than 0.6% of nickel and cobalt and iron.

A number of BeCu finger stock profiles available from Schlegel Electronic Materials, such as Folded Series FS, have compression forces from about 20 lb/linear foot to 40 lb/linear foot. Force is a function of the material thickness, the spring temper, the amount of deflection, and the bend radius. The Schlegel catalog includes a graph showing an almost linear inverse relationship between a gasket’s compressed height and the required compression force.1 Although these parts may be typical, a wide range of deflection force is available for finger stock from different manufacturers.

BeCu finger stock can be flexed a huge number of times, while staying within its elastic limits, without failing. Recommended deflection is between 20% and 60% of the gap size to ensure good contact. Nevertheless, fatigue is cumulative, so the level to which the material may continue to be stressed is reduced as the number of bending cycles increases. The fatigue stress that causes failure after 100,000,000 bending cycles is about 25% of the ultimate tensile strength. For EMI applications, failure caused by fatigue would take so many open/close operations that it’s usually not a consideration.

However, fatigue depends on a large number of variables that influence a test specimen’s tendency to form microscopic surface cracks. Technical papers cite surface finish—test specimens usually are polished—and the amount of corrosion as two major factors. Actual fatigue testing is a statistical exercise because even samples cut from the same bar of material will produce differing fatigue test results.2

A Parker Chomerics catalog states that stainless steel gaskets can be an economical solution in less demanding applications. Importantly, the catalog adds, “stainless steel gaskets have higher compression set than BeCu when used in demanding applications.”3

Compression set is a measure of how well a gasket returns to its uncompressed size after being compressed by a certain amount, for a length of time, at a particular temperature. The parameter is a common selection variable for elastomer gasket material but can be used to describe the performance of any compressible gasket. In the case of stainless steel, “having higher compression set” simply means the material doesn’t make as good a spring as BeCu.

Finger stock manufacturers provide BeCu gaskets in a range of finishes from bare metal to several types of plating. When selecting a plating material, the goals include reducing wear, increasing electrical conductivity, and protecting against corrosion by ensuring compatibility with the enclosure on which the gasket is mounted.

The Parker Chomerics catalog explains, “Galvanic corrosion occurs as electrons move from dissimilar metals through an electrolyte such as water or salt spray/fog. The goal of an EMI gasket is to be part of an electrically conductive shield, and the gasket material is typically mated with a structural metal such as aluminum or stainless steel…. To reduce the [chance] for corrosion, the electrical potential difference between the two metals should be minimized. This is where the availability of different finishes on BeCu parts can help.”

A further consideration is safety. Numerous articles have been written about the health hazards associated with beryllium, and some authors have questioned the safety of BeCu gaskets. In fact, OSHA only recently closed the comment period for input to its proposed ruling on “Occupational Exposure to Beryllium and Beryllium Compounds” Docket No. OSHA-H005C-2006-0870. It’s important to note that OSHA’s concern centers on workers in the beryllium industry who frequently may be exposed to elemental beryllium, especially as an airborne dust.4

According to information on many beryllium company websites and those of EMI gasket manufacturers, working with BeCu alloy 25 in the form of finger stock poses no special risk because the beryllium is alloyed with copper—it cannot become separated as elemental beryllium. Workers in smelting operations that actually produce raw beryllium or in recycling plants that remelt products containing beryllium are the people that OSHA strives to protect.

As yet another alternative material, Laird Technologies has developed finger stock gaskets based on what the company calls recyclable clean copper. As the name suggests, no beryllium is used in the products, yet comparable durability and shielding effectiveness are claimed. To back up computer simulations, a special test jig subjected the new gasket material to 500,000 cycles of simulated enclosure door opening and closing.5

Elastomers

The list of silicone-based gasket materials available from Specialty Silicone Products makes interesting reading. Both the range of material characteristics—hardness, flammability, and resistance to solvents and fuel—and the numerous kinds of conductive fillers are extensive. Carbon black, silver-aluminum, nickel-graphite, monel, silver-plated glass beads, silver-nickel, silver-copper, and silver particles are all used to meet specific MIL-DTL-83528 requirements.

For example, SSP-547-65 is a silver-copper silicone designed to meet Type A of the specification, which calls for “silver-plated, copper-filled silicone capable of 110 dB of plane wave shielding effectiveness at 10 GHz with a continuous use temperature range of range of -55°C to +125°C.” In contrast, SSP-2426-30 is a soft electrically conductive silver-aluminum shielding elastomer with a 30-durometer rating.

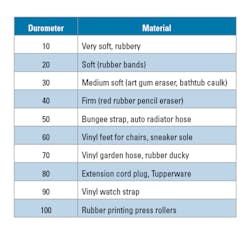

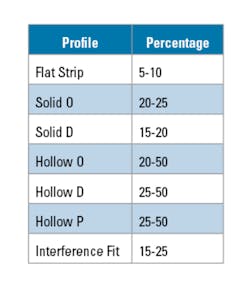

Table 1 gives examples of materials that have specific Shore A hardness values. Although it isn’t the only consideration, a material’s hardness relates to its appropriateness as a gasket.6 Table 2 lists recommended deflection depending on the type of gasket for Laird’s ElectroSeal profiles.

Courtesy of Paramount Industries

Courtesy of Laird Technologies

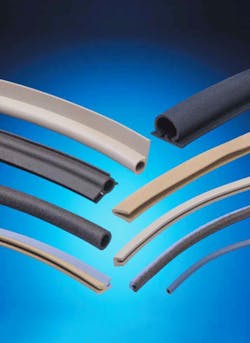

Also addressing gasket hardness and compression, the Parker Chomerics website states, “We do not recommend basing material selection primarily on hardness. Unlike unfilled elastomers, material hardness is not always an accurate indicator of deflection properties [for filled elastomers]. The geometry of the gasket is generally the most important determinant of deflection under load. For applications requiring large gasket deflection with minimum closure force, a hollow part geometry is recommended” (Figure 2).

Courtesy of Parker Chomerics

A gasket’s force vs. deflection characteristic often is quoted as lb/inch or lb/foot. This is the amount of force required to deflect a 1-inch or 1-foot length of material by a certain amount—20% to 50% listed in Table 2 for a hollow “O” section such as Laird Technologies’ ElectroSeal O-strip tubing number 8864-0110. One of the advantages of BeCu finger stock is its low compression force that still gives good shielding performance. Solid conductive elastomers typically require a higher force for a similar deflection. A hollow section of a relatively hard material can have better mechanical wear than a very soft rubber and still exhibit a reasonable compression force.

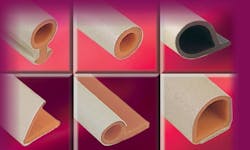

Rather than fill an elastomer with conductive particles, some EMI gasket manufacturers, such as Vanguard Products, co-extrude a thin layer of conductive material over a nonconductive elastomer core (Figure 3). In addition to reducing cost because less of the expensive filler is needed, Vanguard claims that the mechanical properties of the core material are unaffected in the company’s dual-elastomer Ultra-Vanshield range of EMI gaskets. In particular, the compression set of a filled elastomer gasket generally is higher than that of a plain unfilled elastomer.7

Courtesy of Vanguard Products

For example, Auburn Manufacturing’s website states that the company’s solid silicone rubber exhibits a lower compression set than any other elastomer—about 15% after 72 hours at 302°F. Intertek’s Plastics Technology Laboratory website describes a compression set under constant deflection test according to ASTM D395-B. The site states, “The thickness of the original specimen is measured. The specimen is then placed between spacers and in the compression device. The specimen is compressed to 25% of its original height, using spacers to accurately measure the compression. Within two hours of assembly, the compression device is placed in an oven at a specified temperature for the suggested time periods of 22 hours and 70 hours. After removing the sample from the oven, the specimen is allowed to cool for 30 minutes before measuring the final thickness.”

Compression set is expressed as a percentage of the original deflection

CB = [(to – ti)/(to – tn)] x 100

where: CB = compression set

to = original thickness of the specimen

ti = final thickness of the specimen

tn = thickness of the space bars used

For a 0.5-inch thick specimen, the compressed height would be 0.125-inch—25% of the original height. The spacers used to ensure the compressed thickness are 0.125-inch thick. Assume the final thickness is 0.45 inch. Then the compression set is 100 × (0.5 – 0.45)/(0.5 – 0.125) = 13.3%—similar to the performance Auburn quotes.

In comparison, the Parker Chomerics website lists a large number of conductive elastomer molded or extruded Cho-Seal gaskets that typically have compression set between 30% and 50%. No doubt, the type of filler makes a difference, but the conclusion on the Vanguard Products website that fillers increase silicone compression set seems broadly correct.

The force required to cause 10% deflection of a solid 0.125-inch diameter filled Series 5000 elastomer EMI gasket (part No. 5011-12000-xx, where xx designates the combination of elastomer and conductive filler) from MAJR Products is approximately 6 lb/linear inch, or 72 lb/linear foot.8 In comparison, a Vanguard co-extruded dual-elastomer Ultra-Vanshield tubular gasket requires about 2 lb/linear inch (24 lb/linear foot) to

deflect 40%.7

Interestingly, Parker Chomerics makes a type of coextruded gasket that molds conductive next to nonconductive material. One form is a strip with a thicker cross section near both edges. The edge with the conductive material performs the EMC shielding. The other edge is positioned toward the outside of the enclosure and makes the environmental seal. Because there is no galvanic incompatibility—there are no metallic filler particles in that part of the gasket—there is no corrosion caused by the gasket.

Elastomers can be processed to have a foam structure, which generally is much easier to compress than the same material in solid form. Parker Chomerics’ Soft-Shield 3500 is one of several series of gaskets that the company makes based on a foam urethane core wrapped or plated with conductive material. As information on the company’s website states, the “… commercial EMI gasket product offering consists of multiple profiles of a conductive fabric wrapped around open cell urethane foam. The more than 250 product profiles consist of rectangular, D-shape, P-shape, stealth, C-fold, and knife-edge. These profiles offer an EMI gasket which can perform with less than a 1 lb per inch force.”

Alternative gasket materials

Continuing with the foam elastomer theme, several companies have combined metallic or plated fibers with elastomers to make low-resistance gaskets that also have environmental sealing capabilities. Parker Chromerics’ Soft-Shield 4850 Z-axis conductive strip gaskets provide up to 80-dB EMI shielding at lower cost. Like coextruded gaskets that retain an unfilled elastomer core, the 4850 products exhibit very good compression set and yet require low deflection force.

Rather than a foam core wrapped with a conductive fabric, some products such as Laird’s knitted conductive gaskets have a knitted covering made from conducting fibers or metal wire. As a document on the Laird website explains, “Knitted gaskets can be made from a variety of metal wires, including monel, tin-plated copper-clad steel, or aluminum. It is cost-effective for low cycling applications with high shielding effectiveness over a broad frequency range.… Popular product lines include the ElectroNit All Mesh, which is the most economical gasket for low cycling applications and is designed to offer the highest levels of attenuation.… CuBe Mesh offers superb resiliency for consistent, point-to-point contact requiring the lowest compression forces among all other shielding materials and configurations. Elastomer Core Mesh is an optimum solution for combining excellent shielding performance with a high degree of elasticity. Electro-Con oriented wire provides EMI protection and seals against moisture or rain on cast or machined surfaces.”9

Courtesy of Spira Manufacturing

Taking a very different approach, Spira Manufacturing’s Spira-Shield gasket uses a tight spiral wound from spring temper BeCu that is tin plated to improve conductivity and shielding properties (Figure 4). Three resiliencies are available: standard with 30 lb/linear inch force vs. deflection, moderate with 10 lb/linear inch, and low with 1.5 lb/linear inch. The product can be made with diameters from 0.034 inch to 1.5 inches and offers shielding effectiveness up to 165 dB depending on the application.

References

- “EMI Fingerstock,” Schlegel Electronic Materials, January 2016.

- “Metal fatigue—why metal parts fail from repeatedly applied loads,” EPI.

- “Fingerstock Product Catalog, Beryllium-Copper and Stainless Steel EMI Gaskets,” Parker Chomerics, 2016.

- “Occupational Exposure to Beryllium and Beryllium Compounds,” Federal Register, October 2015.

- “Laird Technologies launches beryllium-free shielding material for slotted applications,” Laird Technologies Press Release, Aug. 15, 2006.

- “Durometer made easy, durometer hardness scales—general reference guide,” Paramount Industries, 2008.

- Ultra-Vanshield RFI/EMI dual elastomer shielding gaskets,” Vanguard Products, 2009.

- “Conductive elastomer,” MAJR Products, 2016.

- Noto, J., et al, “Automotive EMI Shielding – Controlling Automotive Electronic Emissions and Susceptibility with Proper EMI Suppression Methods,” Laird Technologies, April, 2010.

For more information

About the Author