ESD-rated ceramic-capacitor portfolio

This ESD-rated ceramic capacitor series has been expanded into a complete product portfolio. Automotive and commercial grades are now available in EIA 0402, 0603, 0805, and 1206 case sizes with voltage ratings of 16 to 250 VDC. These devices provide miniaturization and enhanced flexibility to optimize ESD suppression, RF filtering, blocking, sensing, and circuit protection. The product portfolio offers additional case sizes, voltage ranges, capacitance values, and ESD ratings with more options for a wider variety of customer applications. Design engineers can choose either X7R or C0G dielectric for circuits requiring Class-II or Class-I stability and noise performance with the ability to design to given ESD criteria per the Human Body Model (HBM) AEC-Q200-002. ESD events may cause undesirable operation in a circuit and possible damage due to human contact, which is a major cause of electronic equipment failures during circuit assembly or in the field. These issues are estimated to reduce assembly-line productivity by up to 33%. This vendor’s ESD-rated capacitors enhance circuit protection of integrated circuits, and smaller dimensions simplify designs while minimizing impact on overall form factor.Kemet

Compact 6- to 30-A 250-V EMC filters

The RSEV Series EMC filters, with a voltage of 250 VAC/VDC and a choice of 6-, 10-, 16-, 20-, and 30-A current ratings, have an integrated touch-resistant terminal block with recessed, captive screws. Hardware cannot be misplaced or dropped inside the system enclosure. The filters are suitable for general-purpose use in a range of industrial and communications equipment. The RSEV is chassis-mountable or, with an optional kit, can be attached to industry-standard DIN rails. The maximum weight is 150 g for the 30-A model. All models share a common package size of 85 mm × 39 mm × 30 mm (L x W x H) and a 37% reduction in size compared with previous models (RSEN 30A). The filters have an operating ambient temperature rating of -25 to +85°C with derating above 55°C. The series has a maximum earth leakage current of 1 mA at 250 VAC, 60 Hz, and is safety certified to UL 1283, CSA C22.2 No. 8, and EN 60939-3 standards with compliancy to the RoHS2 Directive.TDK-Lambda

Audio test speech intelligibility measurement

A speech intelligibility measurement option has been added to this vendor’s APx500 audio test software based upon the ABC-MRT speech-processing algorithm. To eliminate the time, complexity, and expense of the traditional human subject-based methodology, ABC-MRT uses a form of automatic speech recognition (ASR) to conduct an automated measurement that is closely correlated—greater than 95%—to a Modified Rhyme Test. An added benefit of ABC-MRT is its use of real speech (English only), allowing it to support the testing of systems that use noise suppression and/or codecs that only pass speech. The ABC-MRT option allows developers to measure the speech intelligibility of their designs with the vendor’s instrumentation and use that same equipment for the rest of their audio and electro-acoustic test requirements. Once installed, the ABC-MRT measurement can be easily incorporated into any test sequence. The ABC-MRT software option (APX-SW- ABC-MRT) is available now and retails for $2,100. It requires APx500 audio measurement software release v4.5.2 (or later) and is compatible with all analyzers in the APx500 Series. Audio Precision

Spacers for automated assembly

New board-to-board connectors for SMT assembly include the WA-SMST with a through-hole of 4.5 mm in diameter and the WA-SMSI with an M4 internal thread. Both versions are available for spacing of 1 to 10 mm in 1-mm steps. The spacers are made of tinned-steel, and their large component diameters and the resulting large contact area guarantee high holding forces. The components withstand extraction forces averaging 610 N. The SMD spacers are now available from stock in any quantity, loose or as a component reel. Free samples can be requested. Würth Elektronik eiSos

Combined tilt and telescopic table

The HD-150 combined tilt and telescopic table allows an object such as an SMT/PCB assembly or a medical device to be tilted up to 30o in all directions, and at various user-adjustable heights under one of the vendor’s video microscope cameras. The HD-150 is a universal solution, usable with any of the vendor’s all-in-one cameras (C12 Series, U10, and the new F30) when using additional +2, +3, and +5 diopter macro magnification lenses. The HD-150 features a 3-stage telescopic post that provides convenient height steps and allows step-less height adjustment between 52 to 155 mm. The object table has the same dimensions and format as the HD-029 tilt table and uses the same antistatic coated material as other accessories, and the surface of the tilt board is covered with a high-friction antistatic mat to keep the object under inspection firmly in place. Four slots are available for attaching HD-128 magnetic pegs or custom-made fixtures and holders.Inspectis

4-channel PXI SMU

The new GX3104 4-channel PXI source measure unit (SMU) is a precision 3U PXI module that forces and senses both voltage and current over a range of ±20 V and up to ± 1 A. The module’s unique flex-power architecture offers users the option to configure the SMU as a 4-channel, 250-mA/channel SMU or as a single-channel, 1-A SMU—providing test engineers the flexibility to support both high-current or multichannel SMU applications with one module. The four channels are electrically isolated from the PXI power supply and share a common, isolated ground. In addition, all module power is provided by the PXI bus, eliminating the need for bulky, external DC power supplies. The GX3104 is supplied with a full-featured API and UI, as well as full documentation, online help files, and GtLinux, a software package that provides support for Linux 32/64 operating systems. Marvin Test Solutions

Fault-insertion switching

This vendor has expanded its range of PXI fault-insertion switching. The new Model 40-202 PXI fault-insertion switches, available with 22 or 11 fault-insertion channels, were primarily designed to simulate fault conditions in automotive and avionics test applications involving the reliability testing of safety-critical controllers. They are specifically designed for differential signaling requirements, with capabilities to insert three different types of fault condition between the test fixture and the equipment under test: open-circuit, short-circuit between signal pairs, and short-circuit to user-applied fault conditions such as power or ground. These new models complement a range of PXI fault-insertion switches, which are typically used in hardware-in-the-loop simulation applications for electronic control unit validation. Relays in-line with the signal paths allow open-circuit conditions to be simulated on either side or both sides of a signal pair. Relays between each channel pair enable adjacent signals to be shorted, and relays between signal paths and the fault connection allow the application of external fault conditions. The switching topology of the 40-202 fault insertion switches allows switching channels to be interconnected so that complex fault-insertion channels can be constructed. These products are supported by the vendor’s eBIRST switching-system test tools, which provide a quick and easy way of finding relay failures within the modules. In addition, Switch Path Manager signal-routing software may be used to simplify signal routing through complex switching systems. Pickering Interfaces

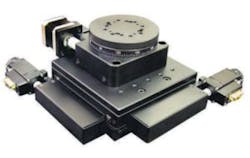

XY-theta alignment stage

The XYR-03-01 alignment stage is a high-resolution, high-repeatability XY-theta stage for such applications as angular glass cutting and grinding, wafer alignment, semiconductor handling, laser cutting, and drilling. The linear resolution of the X and Y axis is 5 µ (non-micro-step) or 0.125 µ (20 micro-steps per step-motor driver in use), the repeatability is 1.5 µ, and positional accuracy is 5 µ. Its 1-mm per-turn lead screws and preloaded V-groove and crossed roller bearings add to the high precision and stiffness of the XYR-03-01 alignment stage. The linear travel of the X and Y axes is 50 mm x 50 mm. The 100-mm-diameter theta stage is driven by a precision 90:1 ratio worm gear. The resolution of the theta stage is 0.02o (non micro-step) or 0.001o (20 micro-steps per step-motor driver in use). Repeatability is 0.005o, positional accuracy is 0.01o, and backlash is 0.005o. Two-phase stepper motors are standard. The knob for manual adjustments of each axis can be replaced with an incremental encoder for position verification or closed loop operation. These black anodized aluminum XY-theta stages are easy to integrate into new or existing systems. Compatible motion controllers are available, and the XYR-03-01 alignment stage can also be ordered as a complete plug-and-play system. Optimal Engineering Systems

About the Author

Sign up for our eNewsletters

Get the latest news and updates