Lead-Free Quantum Dots Bring SWIR Closer to Consumers

What you’ll learn:

- How SWIR-sensitive quantum dots will benefit a range of markets, including consumer electronics, automotive, and medical.

- The latest breakthroughs in QD development.

- How lead-free QDs overcome the performance barriers of other SWIR sensing and imaging solutions.

Unless you work in a specialist field, you probably don’t have immediate access to a shortwave-infrared (SWIR) imager. Not yet, at least. Most people outside the industry probably don’t even know what a SWIR imager is, and as a result, the idea that this technology will change our lives may seem difficult to believe.

But a decade ago, the same could be said about many other technologies now considered commonplace. In 2013—a year before the launch of Amazon’s Echo device (now known as “Alexa”)—the idea of a voice-activated virtual assistant that you could buy in stores seemed the stuff of science fiction. The same could be said of artificial intelligence. While we may have been familiar with the concept, readily accessible programs like ChatGPT that can mimic human-like writing with reasonable accuracy at the press of a button were unimaginable.

The difference is that widespread proliferation of SWIR for imaging and sensing isn’t a decade away. It isn’t even five years off. Thanks to the revolution of high-performance, scalable, SWIR-sensitive quantum-dot (QD) materials, we stand on the cusp of a technological revolution—and the technology that will power it is already here.

The Growing SWIR Market

Demand for SWIR imaging and sensing is expanding rapidly: Analysts at Yole Intelligence predict that this market will reach a value of $2.9 billion by 2028. Such growth, up from $322 million today, will result from major multinational electronics manufacturers increasingly adopting cutting-edge SWIR sensitive technologies, and QDs are best positioned to benefit.

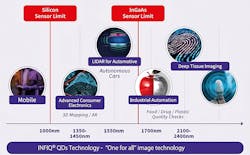

Compared with other common sensing methods, QDs offer two primary advantages. First, they’re high performance. Unlike certain other technologies, QDs can be tuned to respond to the entirety of the SWIR wavelength and more, granting them immense flexibility for sensing applications. Second, QDs cost just a fraction of the price to manufacture compared with solutions like indium-gallium-arsenide (InGaAs) sensors, lowering the development cost by orders of magnitude and suiting them for a much broader application range.

Until recently, widespread adoption of QDs for sensing purposes was limited by their scalability. Existing formulation processes relied on multiple depositions of QDs in 14-16 layers, with each step requiring individual chemical treatments and washes. This method is time-consuming and prone to defects in the films, such as cracking and inefficient exchange process, limiting the ability to produce QDs at sufficient scale and quality to meet industry demand.

A New QD Deposition Process

Quantum Science, a specialist nanomaterials developer and creator of the INFIQ QD technology (see figure), overcame this challenge with a new approach to QD synthesis by producing QDs in ink form. It enables single-step deposition of the required thickness and uniformity for QD films in a controlled manner suitable for mass production.

This process also minimizes chemical and solvent waste, energy consumption, and production time. Furthermore, it prevents unwanted QD surface oxidation during isolation and purification, resulting in high-quality and high-yield QD products.

High-scalability INFIQ QDs are tunable to wavelengths from 1,400 to over 2,000 nm. The company can also provide full flow development from materials to the device, simplifying integration of QDs. With this technology available, high-performance, affordable SWIR imaging and sensing is possible for a far wider selection of industries.

Current Use Cases for SWIR Imaging and Sensing

SWIR isn’t just a technology of the future. Because SWIR imagers and sensors can detect specific reflectance spectral signatures, they’re already being used for specialist purposes in everything from food and pharmaceuticals to recycled plastics sorting and airborne crop monitoring.

For example, in the world of machine vision, SWIR technology is being leveraged to enhance existing capabilities and unlock new applications. With this technology, it’s possible to create sensors that can “see” through otherwise opaque materials like certain plastics, facilitating monitoring of liquid or powder levels in sealed containers. Such sensors are also able to see through silicon, meaning they can monitor contact quality in semiconductor component fabrications.

Food and beverage industries benefit from SWIR sensors, too. Traditional food-sorting systems rely on the visible spectrum to analyze produce by shape or color. This means that while they can detect surface defects and contaminants, less visible defects, such as bruised or rotting produce, or foreign objects embedded in the food, can’t be identified and are more likely to pass through the sorting process.

However, water’s absorption coefficient peaks in the SWIR range at 1,440 nm. This means SWIR wavelengths are often absorbed by water and thus show up as a darker area on a SWIR imager. As a result, SWIR imagers can be used to detect bruises in food before they have fully formed or locate the absence of moisture in food that could indicate the presence of foreign objects.

More advanced hyperspectral imaging systems can also detect everything from bacteria to food ripeness without causing damage. This helps reduce food waste—an enormous environmental issue.

Because SWIR matches the emission wavelengths of other devices, it’s being used in solar panel quality monitoring, capturing electroluminescence and photoluminescence images. It’s also employed in industrial and telecom lasers that can emit SWIR, making it possible for cameras to evaluate their intensity or spectral profile. These use cases have no functional alternative to SWIR.

Moreover, SWIR wavelengths have a number of applications in the medical market. Because this light penetrates deeper into tissue than other wavelengths, and causes less damage than alternatives like X-rays, it’s ideal for detecting “hidden” conditions long before symptoms would otherwise emerge. For example, cancer and certain other diseases have specific spectral signatures in SWIR, enabling early pathology detection.

“Dotting” the Consumer Landscape with Lead-Free QDs

QDs already have the potential to improve a staggering range of consumer technologies. From self-driving cars to fitness trackers, making SWIR sensing widely available will fuel rapid developments in some of the systems we use every day. The first consumer SWIR technology is predicted to appear in high-end smartphones within a matter of years, providing face ID sensors that are thin enough to fit beneath the OLED screen, facilitating true edge-to-edge screen coverage.

The reason why consumer adoption of SWIR is lagging behind industrial usage is largely due to the relative safety and environmental concerns of using QD materials. The most mature infrared QDs are based on heavy metals such as lead, which, although granting excellent SWIR sensitivity, is prohibited by many major semiconductor manufacturers.

Lead-free QDs have been proposed as an option to overcome this barrier, but to date, the synthesis of lead-free QDs has posed a significant hurdle in achieving precise control over size and shape distribution within the SWIR range. Frequently, creating lead-free QDs requires the use of flammable materials, and the chemical reactions involved in their production are intricate to regulate and scale up effectively.

Quantum Science conquered that challenge through the implementation of innovative synthetic processing, leading to precise control of nanocrystal size within the SWIR range for the first time. As a result, it’s now possible to produce lead-free QD materials that exhibit the necessary performance characteristics and can be manufactured at a scale to meet increasing demand.

On that front, INFIQ lead-free QDs have bridged the performance gap when compared to traditional lead-based QDs. They’re tunable to absorption wavelengths between 800 and 1,550 nm, and SWIR devices fitted with them have demonstrated external quantum efficiency (EQE) in excess of 20% at low bias conditions, with higher EQE possible at a higher operating bias.

Thus, consumer markets now have access to non-toxic, high-performance SWIR-sensitive materials, enabling sensors to capture important invisible data at significantly lower costs compared to current technologies. This advance helps unlock a deep level of information on a massive scale, propelling the development of exciting new features.

From Automotive to Medical to Renewable Energy

For example, current designs for self-driving cars rely on LiDAR to map their surroundings in 3D and internal cameras to monitor the driver. Equipping eye-safe SWIR technology to LiDAR systems boosts the laser power, increasing the effective detection range from 200 to 500 meters. These SWIR sensors will also be better equipped to detect reflective road hazards such as ice or oil, enabling the vehicle to modify its grip for safer driving.

Advanced consumer health electronics, such as fitness trackers, can utilize SWIR lead-free QDs to monitor changes in melanin or hemoglobin levels beneath the skin, offering enhanced health-monitoring capabilities. Non-invasive glucose monitoring will be possible as SWIR lead-free QD-enabled watches can monitor changes instantly, providing a convenient way to track users’ health.

Integration of SWIR lead-free QDs will enable seamless biometrics acquisition, enhancing fingerprint safety and authentication systems. In 3D sensing, SWIR lead-free QDs will support full panel design, enhancing the sensing capabilities. In virtual and augmented reality, these materials will lead to better performance and safety of eye-related features.

However, the impact of lead-free QDs goes beyond enhancing consumer technologies—their proliferation will also contribute to increasing the amount of renewable energy on the grid. By capturing more light, and converting it into energy more efficiently, lead-free QDs can significantly enhance solar-cell performance, in turn helping to reduce carbon emissions and decrease reliance on fossil fuels.

The presence of heavy metals has so far hindered the use of conventional QDs in solar cells. However, high-performing, lead-free options eliminate this roadblock, allowing them to be used in consumer sectors. Lead-free QDs exhibit improved photovoltaic properties that have the potential to greatly enhance the efficiency of solar cells. Through highly efficient light absorption and the possibility of multiple electron generation, these QDs hold promise for significantly boosting the performance of solar-energy conversion.

The QD Revolution

The impact that high-performance, widespread, non-toxic SWIR sensing will have on our lives can’t be emphasized enough. These breakthroughs, from better medical equipment to cleaner power generation, are possible because of rapid advances in QD technology—and crucially, they’re here now.

In a matter of a few years, QDs will be integrated into everyday products. The advent of lead-free QDs will usher in a new era of generational leaps, propelling the field to new heights and enabling applications that were previously unimaginable. The future holds immense potential for these remarkable materials to reshape our world and drive progress in ways we have yet to fully comprehend.

About the Author

Dr. Hao Pang

CEO and Founder, Quantum Science

Dr. Hao Pang is a founder and CEO of Quantum Science Ltd. Hao led the initial fundraising, developed the global business strategy, built the team, and led the technology and IP development. Prior to founding Quantum Science, Hao held a vice president role at a leading LSE-listed technology company, where he led a multi-million USD technology licensing deal, developed the supply chain and successfully introduced the technology into the global electronic markets.

Hao has 19 years of materials research and commercialization experience. He holds a PhD in Materials Chemistry from the University of Strathclyde and an MBA from the Manchester Business School.