Get ready for the next wave of energy-efficient washers

The reason: A lot of callers might think their new machines aren't working properly because the wash water doesn't even cover the clothes in the tub.

Big surprise. The washing dynamics of many such machines are efficient enough to get clothes clean with a seemingly insufficient level of water. Makers of top-loaders, for example, can now precisely control both speed and action of agitators. This lets them use a minimum of water and still clean clothes.

Most of the energy used in clothes washing goes into heating water and drying clean clothes. So getting the job done with less water attacks both problems.

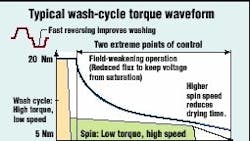

But one of the challenges associated with realizing this kind of energy-efficient wash cycle lies with the washer motor. Energy-efficient washers put tough demands on their motors. Good washing dynamics demand precise control of drum or agitator movement with high torque at speeds that can be lower than 50 rpm. And washer makers are boosting their spin speeds to 1,000 rpm and more to wring out as much moisture as possible at the end of the cycle, thus minimizing drying time.

Washers have historically relied on split-phase induction motors and gearboxes to power the drum and agitator. But such setups don't give the kind of performance energy-efficient washers need at both ends of the speed range.

For this reason, next-generation washers are moving toward use of permanent-magnet synchronous motors. These motors not only generate the kinds of speed and torque needed for high-tech washing, they also do so without an intervening gearbox. The resulting direct-drive system is more efficient than mechanical drives and can be physically smaller besides.

Washer makers are also striving to get costs out of PM motors to make the approach economical enough for mid to lower-end washers. One avenue of investigation in this area is to eliminate Hall-effect sensors and associated electronics normally needed for motor commutation. The alternative is a sensorless, vector-control algorithm built into software. Control parameters for this technique must be tuned to work with specific motor types. So washer makers typically work with motor manufacturers to devise motors and controls optimized for specific washers.

Integrated circuits are now starting to emerge that will let PM motors synthesize the behavior needed for new washers. The most recent example is a sensorless control platform for direct-drive,synchronous PM motors recently developed by International Rectifier. The new chips feature a special field-oriented algorithm for high-dynamic torque control that is said to help washers reduce overall energy consumption by 70%.

The firm's IRMCF341 IC integrates control and analog interface functions for sensorless speed control. A motion-control engine (MCE) on the chip handles actual washer-motor control algorithms. It gets commands from an on-chip 8051 microcontroller which runs application programs. An analog signal engine conditions and converts signals for sensorless control of PM motors. The chip generates pulse-width-modulated outputs which power modules that drive the motor.

The 8051 and MCE share a memory through which the application program can modify setpoints, loop gains, and other constants without changing the MCE programming.

Developers at IR say they worked with a PM motor manufacturer to perfect the chip because of the specificity of sensorless tuning parameters to individual designs. But the ability to reprogram the MCE chip lets it adapt to custom motor designs that are the norm for companies designing new washers.

IR developers also affirm that it was challenging to get their chip to work reliably at both ends of the typical speed range for washers. They say the chip can generate the 30-rpm drum speed typical of front-loading washers set to "delicate" wash settings. Conversely, they also implement 1,200-rpm spin-cycle speeds for U.S. washers and 1,800 rpm for European washers. (The higher rpm stems from the smaller-diameter drums in European machines.)

IR used a field-weakening technique to generate the fastest rotational speeds. This essentially reduces motor back-EMF at high speeds to permit rotations at three times the motor base speed for short periods. The chip also applies zero-vector braking, necessary to prevent overloads in case the motor spins freely after its power has been cut. Otherwise the motor would act as a generator, putting potentially harmful levels of power back into the power bus.

There are also ways of using the chip to detect out-of-balance washes. The program looks for wide variations in either torque or drum speed as an indication of trouble.

IR released PM motor-control chips for air-conditioning systems that share some of the same circuitry as the IRMCF341 chip. The main difference between the two is that the a/c chip includes power-factor control circuitry for switching multiple motors and it targets motors with high horsepower.

Indications are that energy-efficient washers will get a good reception. A 2003 survey by the Consortium for Energy Efficiency (CEE) found that 49% of U.S. households had seen the Energy Star label on washers and that 20% knowingly purchased an Energy Star-qualifying product the previous year. And efficiency in many parts of the world is dictated by law. In the U.S., for example, federal standards for clothes-washer energy use went into effect this past January. By next year, all washers will be required to be 35% more efficient than those put out just a few years ago. And some U.S. states are trying to pass regulations that would place even more stringent water-saving standards on clothes washers.

The situation is similar in Western Europe where it is now almost mandatory to offer "A" scores, the highest grade, both for energy and washing efficiency on the Energy Label. Market watchers say about 60% of all washing machines sold last year in Europe were rated "A" for energy and "A" in wash efficiency.

The quest for energy efficiency may also make front-loading machines more popular. The biggest argument for front-loaders is that they are more energy efficient. Some experts put the market share of front-loaders in the U.S. at 20%, up from about 5% four years ago. The main reason is thought to be better energy efficiency. Nevertheless, energy efficiency in top loaders is rising as well.

MAKE CONTACT

International Rectifier, irf.com