That's cool! Innovative air-conditioning schemes are in the wings

The hot winds of the summer have blown in several new ideas for more efficient air conditioning. Or, more precisely, they've stirred up interest in some traditional techniques that don't need a compressor to cool things down.

Topping the list of a/c topics are absorption and adsorption techniques, the former widely used in recreational vehicles for refrigeration. In rec vehicles, a refrigerant with a low boiling point, usually ammonia, gets absorbed by a liquid sorbent. A heat source then heats up the refrigerant to desorb it from the solution. This generates a refrigerant vapor pressure high enough to condense the refrigerant in a condenser. After evaporation the refrigerant vapor is absorbed back into the solution which is cooled in the absorber. A pump moves the solution around. The heating temperatures for desorption are about 160 deg. F or higher depending in the technology.

Absorption chillers make particular sense when there is waste heat available to vaporize the refrigerant. So they have been used for such commercial buildings as those near coal-fired power plants and steel mills. Now there is interest in bringing absorption chilling to building air conditioning systems of all types using solar methods for the heat source. The idea is worth considering, say experts, because rooftop solar heaters can get water up to temperatures where absorption methods will work.

The problem with such systems is that they are expensive. According to the German firm SolarNext, the operating and maintenance costs of absorption chillers are lower than those of conventional compressor chillers, but the equipment costs more because it is made in such low quantities. So such systems have made the most sense for buildings that have long operating

hours.

And the market of solar air-conditioning is still small: in 2006 only about 100 to 120 solar cooling systems were operating in Europe with about 40% of them in Germany and another 30% in Spain. Still, suppliers such as SolarNext say costs should fall appreciably as solar cooling becomes more mainstream.

Even vehicle air conditioning is a candidate for techniques that eliminate the compressor. That is why Sorption Energy in the UK is developing high-efficiency vehicle air-conditioning powered only by waste heat from the engine cooling system. They company says its technology will work well in current vehicles and is expected to work with hybrid electric vehicles incorporating internal combustion engines -- basically, with any kind of vehicle where there's waste heat.

Sorption claims its technology should cost no more than current systems driven by compressors. Though the idea should work for new models, Sorption says it is unlikely that owners will retro-fit its gear existing cars.

The adsorption heat pumps developed by Sorption use an adsorbent chemical such as silica gel, zeolites and activated carbons, and natural refrigerants such as water, ammonia or methanol. Adsorption refers to the accumulation of refrigerant molecules on a solid adsorbent material such that it forms a film of refrigerant on the surfaces of micropores within the adsorbent. This is different from absorption, in which a substance diffuses into a liquid to form a solution.

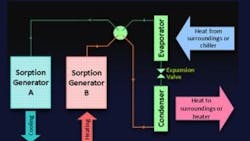

Adsorption systems use a condenser, expansion valve and evaporator similar to those used in conventional compressor-driven systems, plus two "generators" dubbed A and B. As Sorption explains it, initially the cooling cycles starts with generator A charged up and generator B uncharged. Generator A is heated and Generator B is cooled. After leaving generator A the refrigerant vapor passes through a condenser where it liquefies and releases heat, then through an expansion valve which reduces the pressure. Next an evaporator re-vaporises the refrigerant and takes in latent heat. Finally refrigerant reaches generator B where it is adsorbed and the heat of adsorption removed.

At the end of phase A, generator A is discharged and generator B is charged.In phase B the cycle reverses. Generator B is now heated and generator A cooled. The valves in the refrigerant loop are switch so the refrigerant continues to flow from condenser to evaporator. During this cycle generator A re-charges. The process repeats once phase B is complete.

Much of fundamental work on Sorption's technology comes from Prof. Robert Critoph at the University of Warwick School of Engineering. Critoph has been working in the area for over 20 years and has published over 70 papers. Development work at the firm has received over £2.5million of grant-funding from the Engineering and Physical Sciences Research Council of the UK, and from various EU Framework programmes.

Sorption's site: http://www.sorptionenergy.com/index.php

SolarNext: http://www.solarnext.eu/eng/home/home_eng.shtml

Wikipedia absorption refrigeration page: http://en.wikipedia.org/wiki/Adsorption_refrigeration