Distributed energy storage (DES) is an enabling technology for the future power grid. Largely consisting of advanced electrochemical batteries, DES systems increase the efficiency of large centralized power stations, incorporate renewable energy from solar and wind farms, and improve the reliability and cost of energy provided to consumers. Moreover, DES systems facilitate distributed generation by which ordinary consumers can sell the energy generated by their rooftop solar panels back to the utilities during times of peak demand.

To support the rapid evolution of DES technology, DNV KEMA hosts an energy-storage performance testing (ESPT) lab in Chalfont, PA. This article provides an overview of DES technology, current methods for evaluating DES systems at KEMA, and the energy storage data acquisition and control system provided by Bloomy Energy Systems (Bloomy).

About Power Grids

Today’s electric power grid faces many challenges. Originally conceived as centralized unidirectional systems, transmission and distribution systems have been built on the assumption that load varies slowly in the aggregate and that generation sources can be scheduled when needed.1 However, load varies widely according to the time of day, day of the week, temperature, season, location, and availability of technology.

In the United States, electric power generators primarily burn coal and natural gas and account for nearly 40% of greenhouse gas emissions. To reduce carbon emissions and increase energy independence and security, the White House and the U.S. Department of Energy seek to optimize the electric generation portfolio that includes a greater proportion of renewable energy sources such as wind and solar.2 However, most renewable energy sources are intermittent, with wind and solar generation depending on weather conditions.

Consequently, matching the generation of electricity with demand is a formidable challenge. Trends in electric power consumption, such as increased use of plug-in electric vehicles (PEV), further increase the demand for electricity from the grid. When peak demand exceeds maximum generation or transmission capacity, load shedding and power outages occur, leaving consumers without power.

The smart grid attempts to solve these issues through intelligent metering and supply-and-demand economics. Intelligent metering encourages consumers to schedule consumption during off-peak periods and conserve energy during the peaks, a strategy known as demand-side management. Additionally, distributed generation and storage will be increasingly required to take advantage of intermittent renewables and avoid costly overhauls to the existing transmission and distribution infrastructure.

Distributed Energy Storage

DES is a group of energy storage systems located on the distribution-side of the power grid. The systems consist of advanced electrochemical batteries and inverters packaged into larger 1-MW bulk storage units at distribution substations or system feeders or 25-kW to 75-kW community energy storage (CES) systems connected to the secondary transformers that serve a few houses or small commercial loads as well as PEVs. CES systems increase the reliability of the grid by providing energy storage at the edge of the grid where it is best utilized by consumers.

The functional benefits of DES to the power grid include peak shaving, load leveling, power-factor correction, and ancillary services such as frequency regulation and spinning reserve. For example, peak shaving uses the DES systems to supplement the power provided by the central generator during periods of peak demand. This reduces the need to turn on additional peaking power plants, which are more expensive and less efficient than the central generator. The DES batteries then are charged back up during off-peak hours, shifting a portion of the load seen by the power substation from peak to off-peak hours. The efficiency of the central generator is maximized by allowing it to run continuously into a level load.

DES benefits for consumers include backup power, flicker mitigation, and renewable integration. If there’s a problem on the grid, the DES can open an isolation contactor to disconnect itself from the grid and power the load directly from the energy stored in the DES batteries. This process is known as islanding. The closer the DES is located to the edge of the grid, the more reliable and beneficial the service to consumers. Additionally, ordinary consumers with rooftop photovoltaic (PV) solar panels can sell the power they generate back to the utilities by charging the batteries of their local CES. Hence, DES facilitates distributed generation as well as storage.

Challenges with Wide-Scale DES Implementation

The current challenges with DES include energy density, cost, limited operational experience, and lack of standards. The sodium-sulfur and lithium-ion (Li-Ion) battery technologies used in DES systems are rapidly evolving, with steady improvements in energy density. Also, the Li-Ion batteries used in CES systems are very similar or even the same as those used in PEVs. As PEV manufacturing volume increases, the cost of advanced batteries is expected to decrease via economies of scale, reducing the cost of CES systems. The U.S. Department of Energy has funded a project for which PEV batteries are recycled and reused in CES systems.3

There is a lack of standards governing DES performance and test. Present-day battery testing on new technology has outpaced the standards development process. There are standards for PV system components, wind generation, and conventional batteries. However, there currently are no IEEE, UL, or IEC standards that pertain specifically to this new generation of integrated battery energy storage system products.4

For DES to effectively function as a larger unit, the individual DES units need to be controlled and dispatched in an aggregated manner. IEEE 1547 and IEC provide grid-interconnection standards. However, communications and control are not yet standardized. NIST currently is developing energy storage interconnection guidelines as part of its framework and roadmap for smart grid and interoperability standards.

The vast majority of deployed DES systems will be owned and operated by regulated electric utilities that are cost-sensitive and put a high premium on system reliability. Technological conservatism of regulated industries will require extensive validation and testing of new technology before deploying it on a distribution system.1 However, lack of standard tests makes it challenging to compare technologies and applications.

Energy Storage Performance Test Facility

The DNV KEMA ESPT lab is a comprehensive facility capable of testing components, such as cells, stacks, and inverters—all the way up to megawatt utility-scale energy storage systems. It contains a utility-grid substation on the premises (Figure 1) for connecting DES systems to the actual utility electric grid. The substation provides power to a dedicated 2.5-MVA transformer inside the ESPT lab (Figure 2), which serves as a point of common coupling (PCC) to the grid. This PCC is specially certified to provide bidirectional power flow to simulate a variety of grid conditions for the DES test device.

The lab transformer steps the 2.4-kV, three-phase grid power down to a configurable voltage from 120 V to 800 V for the DES test circuit. The transformer’s secondary terminals are shown in Figure 3. The substation and transformer can be used both as a power source in the charge mode and a load in the discharge mode, enabling real-life test conditions to evaluate functions such as interconnection compatibility, frequency, and ramp rate.

Battery-cell and stack performance and electrical, mechanical, and thermal destructive testing can be performed in accordance with IEC, MIL, UL, and UN standards. Overall, the lab can verify the performance, interoperability, and integration of DES systems.

Data Acquisition and Control System

KEMA uses the Energy Storage System Data Acquisition and Control (ESS DAC) system provided by Bloomy. The ESS DAC system is designed using commercial-off-the-shelf hardware and software including National Instruments (NI) PXI modular instruments, Bloomy EnergyMAX power monitoring software, and NI DIAdem data processing software.

Physically, the ESS DAC system consists of a controller unit (Figure 4) and one or more acquisition units (Figure 5), each housed in protective mobile containers. The acquisition units contain all of the measurement and control hardware that connects directly to the DES system’s power, communications, and control input and output (I/O) points. It is located in close proximity to the DES test unit for maximum signal integrity.

The controller unit is a mobile workstation that runs the human machine interface that the operator controls. It is located a safe distance away from the DES and communicates to one or more acquisition units over a fiber-optic communications link. Consequently, there is no electrically conductive path between the DES test unit and the ESS DAC control unit, ensuring operator safety.

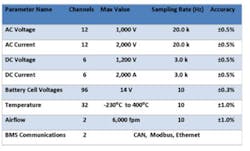

The acquisition unit handles a variety of signal types (Table 1). Three-phase and single-phase AC voltages and currents are measured from the lab’s step-down transformer, the DES line terminals, the load, and other locations of interest within the DES. Measurements include battery voltages (and the individual cell and stack voltages if accessible), temperatures, and other signals. The acquisition unit also acquires system parameters including air flow and temperatures and controls analog outputs and relays for system simulation. The DES battery management system (BMS) can be monitored and controlled via optional communications, which support CAN, Modbus, Ethernet, and other protocols. Isolated transducers are used to step the high-level voltage and currents down to low-level signals, which are safely digitized using the NI PXI instrumentation to maintain high accuracy, resolution, and bandwidth.

The controller unit contains a rack-mount computer and real-time controller that run Bloomy EnergyMAX software as a distributed application. The acquisition engine runs deterministically on the real-time controller. It continuously acquires measurement data, updates control outputs, communicates to the BMS, and maintains synchronization of all data. The user interface runs on the rack-mount computer under Windows. The operator uses it to configure and calibrate each measurement channel and monitor the transducer data in engineering units and raw voltage or current units (Figure 6).

The ESS DAC system provides real-time, synchronous, and deterministic measurements for AC and DC voltages and currents, general I/O, and communications. It maintains safe operation through fiber-optic connections and isolation transducers and offers measurement reliability and accuracy for flexible test lengths, ranging from days to months.

Part 2

Part 2 of this series, which will be published in the January 2013 issue of EE-Evaluation Engineering, will cover DES performance specifications and test requirements, DES test scenarios, and performance reports.

References

1. Distributed Energy Storage: Serving National Interests, National Alliance for Advanced Technology Batteries, 2012.

2. Blueprint for a Secure Energy Future, The White House, March 30, 2011.

3. Carlson, N., “Detroit Edison’s Advanced Implementation of Community Energy Storage Systems for Grid Support,” DE-OE0000229, Oct. 20, 2011.

4. Lubkeman, D., Leufkens, P., and Feldman, A., “Battery Energy Storage Testing for Grid Standard Compliance and Application Performance,” 21st International Conference on Electricity Distribution, Paper 0674, June 2011.

About the Authors

Peter Blume is president of Bloomy Controls. With more than 20 years of leadership experience, he has helped establish engineering best practices through many published articles and presentations and as author of The LabVIEW Style Book. [email protected]

Kevin Lindenmuth is the systems and test development engineer for DNV KEMA. He primarily is involved with battery cell test program development and performing tests in the KEMA Battery Test Facility.

Jonathan Murray is the business unit manager for Bloomy Energy Systems, a business unit of Bloomy Controls. Murray also has held positions in systems engineering, project management, and business development.