A Closer Look at Tektronix’s 6 Series B Mixed-Signal Oscilloscope with Mark Briscoe

Recently Tektronix introduced the latest version Mixed Signal Oscilloscope (MSO), the 6 Series B, extending the performance of their Mainstream Oscilloscopes Portfolio to 10 GHz and 50 GS/sec. Targeting high-speed data management in embedded designs, the enhanced 6 Series B MSO offers high signal fidelity, with 12-bit ADCs and extremely low noise, and up to 8 FlexChannel inputs, enabling users to analyze and debug advanced embedded systems.

In addition, the company is also introducing the TDP7710 TriMode Probe, which extends the line of TriMode probes to match the advancements of the latest oscilloscopes. Presented as the industry’s first oscilloscope with bandwidth more than 2 GHz to offer 4, 6, or 8 channels, the combination addresses the need to test next-gen systems with advanced video, motion, and 3D sensing functionality. With up to 10 GHz of upgradable bandwidth, and a sample rate, the upgraded system enables a better visibility of signals, contributing less than 51.1 μV of noise at 1 mV/div and 1 GHz, and less than 1.39mV of noise at 50 mV/div and 10 GHz.

A chat with Mark Briscoe

To get a bit more of a handle on how the new ‘scope can aid engineers in their efforts, we reached out to Mark Briscoe of the company’s Mainstream Scopes Product Line. We talked to him about the 6 Series, what it means for the company, and what it means to the electronic systems designer.

EE: Hi Mark, thanks for talking to us. There are two realities when it comes to solutions today, actually three. The two that we always think of, does it work, and is it cost-effective, and then the new one, how will it work in the new world of COVID? But in this case, we can stick to the first two.

Mark Briscoe: Okay, and thanks for having me here.

EE: ...unless it plugs in and can support a telepresence and collaborative development environment.

Mark Briscoe: Yeah. Actually, we're using it ourselves for collaborative development. So I can talk a little bit about some of that.

EE: Well then bingo, why don't we start with that. I'll bounce some of the numbers I have from the Endeavor Business Media Salary Survey off of you. One of the questions was on their current design project. Obviously it's going to be all over the map, but the two peaks in the responses, 13% responded industrial controls, and 15% responded mobile equipment. Every other response was under 6%. So industrial control, so there's industry 4.0, and mobile equipment, in the IOT.

Mark Briscoe: Yeah. Cellular and mobile. Gosh, mobile is a huge trend for us.

EE: We can imagine. And a quarter of the respondents say test equipment has a major impact on their design, the number one single channel. One of the things that I've observed is, we've entered an environment of constant test. There's no such thing as saying, test here or test there. We're testing everywhere now, right?

Mark Briscoe: Test technology has helped enable that.

EE: Exactly. And now, odds are, they're doing simulations beforehand, they're constantly testing on the bench, they're testing now constantly in manufacture. I've been to Chinese factories that they've managed to achieve Six Sigma by literally putting a test station at the end of each process step. Testing is becoming ubiquitous and constant. And so, these powerful tools, these more accessible powerful tools like the 6 Series B, I think it really speaks to it. Especially if you can use it for collaborative effort.

Mark Briscoe: Some of the things we're doing on that side of the fence, what has happened this year, and partially driven by the work from home. But we were doing it before that because the value is there no matter whether you're working from home all the time or part of the time, or you're spread over the globe.

Because we also have design, we also have manufacturing in Oregon, we have manufacturing in China, we have development in India, in Cleveland, in Beaverton. So we're constantly collaborating across the globe ourselves. So we have tools on the instrument. Some of the things we're actually doing is, because the instrument can be configured to run Windows, we can also use other tools like webcams and stuff like that.

We also have this capability to serve the interface over a web connection, so you can connect to it via any browser. So any internet browser from India can dial into a scope in Oregon, very, very easily. You just put in the IP address of it and it serves up the interface. We have people in India driving the scope and people in Oregon holding a webcam, showing what they're probing so these folks can see it, holding the probes on the device under test.

Which in a lot of instances for us are oscilloscope boards. We're doing things as we're finalizing the product. So we're doing this ourselves, but our customers do this all the time as well. And each scope is something that has been around for 20 years. We first built that product functionality in our TDS3000, which is the best selling scope ever at Tektronix, and we believe probably in the world ever, in terms of dollar volume.

This 6 Series has a lot in common with that product. That product was successful because it had something for everyone. It was the combination of a bunch of cool features put into one product at an accessible price. So it had something for everyone. It was the first accessible color scope in that space. It had a really high sample rate for its time because of the ASIC technology that was in it, and a new user interface in terms of digital scopes.

The user interface

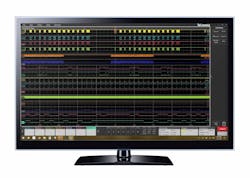

This scope today has a super innovative user interface and experience as well. It's one of the benefits that customers get from it. Because everybody can build a one-gig scope these days, it's not technologically hard to do that. So we put effort into finding ways to increase the productivity of our customers.

We know most just want to be able to do their job faster, they don't want to be experts on how a scope works. That's our job, right? So the interface was ground-up redone when the 5 Series launched, about three years ago. And we've been iterating it ever since, adding little things here and there to help with productivity, a lot of it driven by customers, frankly.

We get in front of customers a ton when we do our development and we hear and watch them use the product. And it's like, oh, if we just did this a little bit differently, they could be much faster at what they're doing. So the interface is designed to be super quick to learn. So it's all object-oriented, it's all designed for a touchscreen as the primary interface. I think every other scope in the industry that has a touchscreen was really a mouse-driven interface, and then they added a touchscreen.

This scope, it's built for a touchscreen. So objects are bigger, they're meant to be dragged. If you want to change something on the screen, you just tap it a couple of times and the menu opens there. You don't have to go through menus from a Windows standpoint or anything like that to get to those quickly changeable features.

Customers are noticing, frankly, because what they tell us is, I was very quickly able to do something. That's the first step. They could do something really quickly. And the other thing is, I don't feel afraid to poke things. I feel afraid to experiment, discover, look into the deep dark corners of the UI because I don't feel like I'm going to mess something up. I'm more likely to find what I think I'm going to find when I tap something. That's what they figure out real quick. It's really intuitive.

EE: Before we go into a little bit more on the upgrades in the B-Version, let’s touch a little bit more on the accessibility. The ability to do this level of test in a cost-effective way is important. Because the whole new entrepreneurial maker, independent development, even working from home for a big company, the accessibility of the technology is critical.

Mark Briscoe: We’ve found that it's more difficult to share when people are working from home. Because when you're in the office, and you have 10 people in a work group and you're sharing three oscilloscopes, it's much easier to do that because you can schedule your work time in your lab and your workstation and things like that. When you're at home, everyone's at home. They don't necessarily have the type of access to do the reconfiguration, everything like that. You really needed it on your bench at home, so that means more units.

EE: Right. More units, more money.

Mark Briscoe: We've found large enterprise customers that are working on the devices of tomorrow. Let's say big companies you might've heard of, they are now taking strategies of, if I hire a hardware engineer, they get one of these scopes on their bench. It's just, that's it. It's just, they've gone to that stage now because they're not that expensive in the grand scheme of things.

Those enterprise companies know that it makes them far more effective if they have their own tools sitting there. And these are so flexible. Our first job is to build a Swiss Army Knife, really. And then to layer software tools on top of that, that make specific solutions for certain standards. That's how we build these oscilloscopes. They put a Swiss Army Knife on the desk of their engineer, they can tackle just about any job they need to that day, and oftentimes they don't know what's going to come up.

That's really important, and we're seeing that more and more now. Whether it's a 5 Series or a 6 Series, and usually it's a combination. The 6 Series is great because it does go down to a gigahertz, so you get that kind of, like you said, accessible price point. By the way, we didn't raise the price of the beavers. It came out at the same exact price the non-B was at for the fourth channel, the comparable model. Because it's the right price point, we didn't feel like we needed to add. We're just offering more capability for the same price.

You can go up as you need to. If you need to go to four gigahertz, it's just an incremental set. You don't have to trade the hardware in or anything, it can go all the way to 10 gigahertz now. You have that pretty broad range of capability built into the hardware, that with a license you can just upgrade it later on. Bandwidth upgrades specifically are a usable thing for customers. They love having the insurance. Hey, I know I can go more if I need it in the future. We don't see a ton of people doing that, believe it or not. Most people will just buy what they need upfront still, but they love having the option.

Frankly, it helps us to build the product more cost-effectively when we do that. We have fewer board sets we have to deal with in manufacturing. It makes the product cheaper for us to build, to know that we have to do that. Now, believe it or not, it's more complex, but for us, it ends up being a better product in the end. It's much easier to support. We only have a few build options with the channel count, but the bandwidth is always capable. So we only build one version of the channel path, the signal path.

Custom ASICs

It's much, much easier when you're dealing with custom ASICs, which is the other way we get the cost down. We build our own ASICs, rather than using very expensive FPGAs or something on the back-end. We have our own ASIC that has our special sauce built into it, and that helps us keep that cost down as well.

EE: More channels make sense, lower noise makes sense. The flexible sampling, that's an interesting aspect on how you set up your splits. Can you give me an idea of where you came with the flexible sampling updates in the B-Version?

Mark Briscoe: We had 25 giga samples per second, per channel on the non-B, on only four channels. When you go beyond four channels, we didn't put any more A-to-D power in the instrument. So we have two physical ASICs in there that are scalable A-to-D architecture. So with one of those Tek049 ASICs, that's what we call it, Tek049, we can do one channel at 25 giga sample, or we can do four channels at six and a quarter, or two channels at 12 and a half, that type of thing. So it's scalable.

There's four of those in this box. With the non-B, we had one per channel, 25 gig per channel, very easy. When you go to eight channels, now we have to actually use that, we call it chop two sampling. So we're basically having 12 and a half gig per channel. So on eight channels, you can get 12 and a half giga samples. That architecture allows us to be very flexible in how we configure the instrument.

This product is a little bit different than a lot of our products in the past, where we've had interleaved sampling rates and things like that, because there are so many channels. When you try and route that on the front-end board that has the preamp, you're talking about 10 gigahertz of bandwidth here, trying to route things to multiple A to D. That gets really challenging to hold that signal fidelity that we really want to provide, as well as low noise.

So we chose to do what we call a fixed configuration. There are four samples on an eight-channel instrument, there are two specific channels, channel one and channel five, that can go to 50 giga samples. So we actually take two of those Tek049s, interleaving them together. So that we can sample both of them at 25 gig, offset one of them by 180 degrees in phase, and get an effective 50 giga sample per second rate.

Why did we do that? Because we had 25 gig already, that was plenty even to support 10 gigahertz. We did that because the benefit we get from that isn't so much the extra timing resolution, because it doesn't really improve that much because of the way we're doing the sampling. But what it does do is it reduces noise even more on those channels, because we're sampling two A to Ds with ... they each have their own random noise component from the hardware.

Noise reduction

Because we're effectively averaging those two together, we get another ... theoretically, it would be about a 3dB reduction in noise. It ends up being about a 2dB reduction in noise in practice. But that's about 20% reduction in noise, over what the non-B version was, which is already industry leading. The biggest benefit there to the customer is people that are looking at a little bit larger way form, so kind of one volt, or not even that like, 200 millivolts, let's say full-scale or larger. These are still fairly small signals, but large from today's digital electronics.

They get even more noise reduction than we had in the non-B. And frankly, the non-B has been very successful for us. The biggest reason is the noise performance, technically. It is just game changing in terms of what you can see now, how thin the trace is. Noise shows up as a fuzzy line on an oscilloscope, right? On the old analog oscilloscope, it was the cloud around the phosphorus. Now it's all the same brightness, but it shows up as a fuzzy caterpillar. Nobody likes fuzzy lines when you're an oscilloscope manufacturer. This makes the line much thinner.

Now, when you have a complex signal, what that means is you can actually see true signal detail instead of stuff that was before hidden in the noise. When you're doing power and you're looking at power rails, DC power rails, that aren't supposed to have AC components to them, you can see the actual small ripple on there now that you couldn't even see before, because it was just hidden in the noise.

That's where that becomes super powerful now. So we expect this to even be better. The 5 Series has been selling very well into those applications, specifically because of the eight channels. Because a lot of digital electronics these days might have even up to like 12 power rails, and they want to look at a lot of them at the same time. But all these electronics, not all, but a lot of them, have higher speed standards in the design. It just may be memory, almost everything as DDR3 these days. It might be USB, it might be PCI Express. But they tend to, depending on how well the design was done, they tend to worm their way into the power system.

That's why they needed higher bandwidth on eight channels. Because I need to look at my PCI Express gen one, or my DDR memory that's clocked at a gigabit per second. I couldn't see that on my 5 Series scope because it just wasn't fast enough. Now we've got a product that's fast enough, gives you the same ability to look at all those power rails at the same time. And now you can correlate what's happening on your power rail with what's happening in the rest of your system.

Where you've got the coupling going on, that sort of thing. So that sample rate that we've done and giving you now the ability, when you really need super low noise, you've got two channels you can go get that on. When you need really good noise performance, you've got four or eight channels you can go get that on. So it's flexible. It tries to give them the ability to use what they need. And the four, six and eight channels is another mechanism really to hit price points for people.

Our enterprise customers will tend to lean toward the eight channel models because they all remember a time when they tried to use two scopes together, and it's impossible. And so having eight channels in one is just ... it's a game changer for them because it's like, oh my God. All my tests are built for four, but geez, I just need those couple other channels to look at control lines or something. Whatever it is, they find new uses for it every day, but that's flexible.

EE: Thanks for taking the time with us, Mark. Do you have any final thoughts or last ideas or anything that you think that you haven't brought up yet, that you think is important to bring up to the audience?

Mark Briscoe: Let me think about that for a second. One of the things on the work from home thing that I didn't mention that probably is worthwhile here, it's a complimentary product to the 6 Series, but we call it TekScope. The application that runs on the oscilloscope's super powerful, has all this analysis capability and so forth.

We also do things like import HBase files, for example. So if you run a simulation and you want to compare that to actual acquisitions of an oscilloscope, we can do that in our interface by just importing that HBase file in. We can do CSV files. So any dataset, even datasets from our competitors' oscilloscopes, you can import into this and run it. And so if you're working from home or you're working from your workstation, you're not in front of a scope in the lab, you can run the software and get the same analysis capability.

You can just use your scope, store what we call a session file, which is all of the setup and all of the data. And you can just restore that on your TekScope app or another oscilloscope for that matter. And you're back to just as though you just acquired it, the exact same setup. So super easy to use. It's transferable, so you can put that up onto a Cloud Drive. Somebody in India can open it up in their workstation and see exactly what you are seeing. We've added annotation capability so that you can circle things, point things, put text on the screen so your colleague in another country or even in the other building can see exactly what they're trying to point out as well. So collaboration tools are pretty important, and they've gotten better over time.

About the Author

Alix Paultre

Editor-at-Large, Electronic Design

An Army veteran, Alix Paultre was a signals intelligence soldier on the East/West German border in the early ‘80s, and eventually wound up helping launch and run a publication on consumer electronics for the US military stationed in Europe. Alix first began in this industry in 1998 at Electronic Products magazine, and since then has worked for a variety of publications in the embedded electronic engineering space. Alix currently lives in Wiesbaden, Germany.

Also check out his YouTube watch-collecting channel, Talking Timepieces.