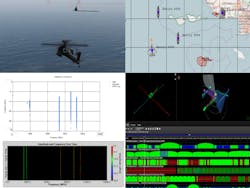

Customers in the military/aerospace test market are looking for a combination of flexibility, sustainability, high performance, and low cost, often achieved through deployment of commercial-off-the-shelf (COTS) products in MIL/aero environments. Specific application areas include upgrading legacy flightline systems to accommodate evolving smart weapons, electronic warfare (EW) and threat detection, and the commercialization of space (NewSpace). Products range from individual instruments and modules to complete systems with software.

Test sets to systems

Products that Marvin Test Solutions offers to help meet the challenges of military/aerospace test applications include the MTS-3060A SmartCan Universal O-Level Armament Test Set. “Marvin Test Solutions developed, qualified, and deployed an innovative O-Level hand-held test set that supports both legacy and Smart weapon armament systems test on fixed, rotary, manned, and unmanned aircraft,” said Stephen T. Sargeant, CEO. “The SmartCan test set combines the power of the big-box test set with the ease of use of a hand-held test set, combining the capabilities of multiple O-Level test sets into a test set that weighs less than 4 lbs.

Sargeant described the MTS-3060A as a battery-operated O-Level test set that provides active test capabilities previously unavailable at the flightline in a hand-held test set. “The SmartCan bridges the ‘armament test gap’ that exists between legacy test sets and today’s Smart armament systems by providing full functional test capability of the MIL-STD-1760 Bus. Designed to functionally test the MIL-STD-1760 Bus that enables Smart munitions, the MTS-3060A SmartCan is deployed today in many countries on F-16, F-15, TA-50, FA-50, Hawk, F-18, F-5, and unmanned aerial vehicles,” Sargeant said, with more deployments planned for 2020.

“The MTS-3060A SmartCan provides the capability to actively test legacy and Smart weapons and supports multiple e-load channels,” Sargeant said. “The SmartCan generates audio and video signals required to test armament for missiles that produce tones or video for employment.”

He explained that the MTS-3060A employs munitions emulation to actively test armament for JDAM, AMRAAM, and other 1760-based weapons systems. “The MTS-3060A SmartCan records test data that is tracked by tail number and can be downloaded for trend analysis and enhanced troubleshooting. Sargeant said the SmartCan has been deployed since 2011, and states that is the only hand-held test set on the flightline to deliver full MIL-STD-1760 Bus functionality testing capabilities (communication, arming, and release), with field-upgradable software.

Sargeant continued, “Advanced cybersecurity features further differentiate the SmartCan, making it the most cybersecure O-Level hand-held test set available. Data encryption, test program set (TPS) development, and a removable hard drive in the form of SD storage all contribute to the cybersecurity of this test set. Our test software, ATEasy, is the most cybersecure test executive on the flightline today and is employed by the SmartCan.”

Marvin also offers the MTS-207 Rugged Field Test Set (O-/I-Level). “The MTS-207 is a state-of-the-art portable PXI platform for field testing and data-acquisition systems,” Sargeant said. “Its proven architecture has been deployed worldwide on the flightline, in the back shop, and in depot as the MTS-206A Maverick Missile, the MTS-209 Common Armament, the AN/TSM-205B Hellfire System, and the MTS-235A F-35 Armament Test Sets. The MTS-207 combines the capabilities of the versatile and powerful PXI architecture in a compact, ultrarugged, flightline-qualified enclosure. The MTS-207 is ideal for military and aerospace test operations in extremely harsh environments.”

In addition, Sargeant cited the TS-321/323 GENASYS Aerospace Test System. “The GENASYS platforms are PXI-based, customizable test systems designed to address a broad range of military and aerospace missions requiring high-performance automated functional electronic test,” he said. “The GENASYS offers best-in-class digital and video test capabilities that effectively address the obsolescence found in decades-old ATE. GENASYS is available with a range of digital, analog, and video instrument options to address both LRU and SRU test as well as supporting depot and production test. The GENASYS switching subsystem supports an ‘any resource to any pin,’ scalable architecture. From testing avionics to complete electronic functional test of entire satellites, GENASYS meets the requirements of a plethora of customers.”

Strategic test approach

According to Nicholas Butler, chief marketing lead for aerospace, defense, and government at NI, the company has been serving the needs of the aerospace and defense industry for more than 40 years. “We understand the complexity of the assets being designed and the mission-critical nature of the end-use applications, which puts an incredible responsibility on test teams to produce components, systems, and platforms of the utmost reliability,” he said. “NI can help our customers develop a more strategic approach to test, so they don’t have to sacrifice quality or reliability for schedule or cost.”

Specifically, Butler said, “NI offers modular, PXI-based measurement and control systems that can be customized for each application (and re-used across applications). As a leading supplier of PXI-based chassis, controllers, and instruments, NI provides a wide spectrum of measurement types, channel counts, frequency support, and form-factors to meet the needs of almost any aerospace and defense test application.”

In addition, Butler said, “NI offers integrated software that gives the customer ultimate control over the operation of their system. TestStand software allows customers to develop customized test sequences and routines, giving them the ability to automate test systems and thus optimize test times and test cost. Veristand software allows customers to perform embedded software validation through hardware-in-the-loop applications where they can import custom models and simulation routines.

FlexLogger software allows our customers to perform configuration-based data-logging, without the need for complex programming, and SystemLink software allows customers to remotely manage systems and data across their entire enterprise. This is an extremely important need for customers that are pursuing digital transformation initiatives.”

Butler added that NI offers service options for customers, including a new consulting services program, which helps customers assess, plan, and implement a more strategic approach to test that helps improve standardization and re-use, decreases the overall cost of test, and helps address future challenges like technology insertion or obsolescence management. “This is especially valuable for customers pursuing digital transformation initiatives, as NI can help incorporate test, test data, and software-defined automation into their overall digital transformation strategy,” he said.

Specific products include the N5193A UXG X-Series agile signal generator, N5194A UXG X-Series agile vector adapter, N7660C Signal Studio for Multi-Emitter Scenario Generation, Z9500A Keysight EW Threat Simulation View, and the Z2098B threat-simulation system.

“We leverage the commercial off the shelf (COTS) expertise we have from other markets such as communications/fifth-generation (5G) to deliver scalable, high-performance EW test equipment in a faster timeline,” Friedrich said. “Our testing equipment provides realism and accuracy for evolving EM spectrum operations with flexible, scalable threat simulation and analysis solutions. We support the detection, identification, and location of RF emitters in the congested EM spectrum to help our customers achieve confidence in their electronic warfare innovations.”

Signal-analysis solutions

“Signal-analysis solutions are vital in streamlining today’s battle for the electromagnetic spectrum, according to David Summers, market development manager, Federal, Anritsu. “A real-time spectrum analyzer (RTSA), such as the Anritsu FieldHe also described Anritsu EasyTest software, which enables experienced military technicians to generate step-by-step test packages to help less experienced users learn how to test specific systems. “The inclusion of images, button pushes, and limit masks enables measurements to be done correctly each and every time,” Added Summers, “Anritsu continues to be a leading provider of 5G test systems globally. Our solutions enable government research facilities to develop mission critical uses and better understand weaknesses of cutting-edge communication technology.”

He described Anritsu’s 4G and 5G communications network emulators as flexible platforms with modular architecture that also find use in MIL/aero design verification. “Our 5G Radio Communication Test Station MT8000A supports frequency range 1 (FR1) up to 7.125 GHz, including band n41, and frequency range 2 (FR2) mmWave bands used by 5G,” he said. “When combined with the Anritsu OTA chamber, the MT8000A enables mmWave band RF measurements and beamforming tests to be made using call connections specified by 3GPP.”

Capture and playback

The Giga-tronics COMPASS, which by the way stands for Coherent Multichannel Playback and Acquisition Streaming System, offers the capture and playback of signals with up to 1 GHz of instantaneous bandwidth anywhere within the RF spectrum to 20 GHz while maintaining a high signal to noise ratio. Systems can be configured with up to 192 TB of solid-state drives (SSDs), allowing more than five hours of record or playback times of very wide bandwidth signals. The system features a variable sample rate that permits the playback of signals recorded on different systems and allows the efficient use of the available storage.”

Gregory Anderson, area sales manager, and Darren Lingafeldt, vice president, eastern USA and Canada, both at Averna, said MIL/aero customers choose to work with the ITAR-registered company because of its broad range of test experience, fielding more than 300 engineers fluent in many programming languages with broad hardware expertise. “We are involved in programs that range from software defined radio to virtual headset optics and alignment,” they said. “This allows us to propose complete custom solutions to not onlyAverna offers custom solutions to serve many MIL/aero applications, according to Anderson and Lingafeldt. “From a test-products point of view, Averna has a specialty in RF test including several off-the-shelf solutions for record and playback,” they said. “The RP-6100 Series is available for testing up to four channels while the RP-6500 enables wideband RF record and playback, up to 500 MHz, across frequencies from 9 kHz to 6 GHz. These are in addition to our Iridium solutions for either development or production.”

Satellite communications

Rohde & Schwarz serves such applications as satellite-communications payload testing, ground-station testing, and on-orbit measurement and monitoring, supporting low-earth-orbit (LEO) satellite systems, high-altitude platform stations (HAPS), and unmanned aircraft systems (UAS), according to Darren McCarthy, aerospace and defense technical marketing manager at Rohde & Schwarz America. The company’s solutions address development and production testing from the chip level up to final system-level verification.

On the benchtop, the R&S NRPM over-the-air (OTA) power-measurement solution can be used for functional integration and testing. “The high-sensitivity, fully calibrated system with low-reflection dual-polarized antenna modules offers reduced system-level measurement uncertainty,” McCarthy said. “And it is scalable to customer requirements.”

Rohde & Schwarz’s R&S AMS OTA performance measurement software and R&S ATS1800C compact antenna test range (CATR) mmWave test chamber is well suited for system-level testing. The chamber is fully shielded to support uninterrupted measurements of antenna, module, and device characterization throughout the entire lifecycle from R&D to conformance, for both active and passive measurements. McCarthy said, “The CATR reflector with optimized edges for uniform power distribution and high-precision surface finishing for minimal deviations in quiet zone, and the near-field to far-field measurement software provide the necessary plane-wave conversion for correlated measurements, all in a very compact area.”

Analyzers and more

“The new Linux API on the RSA300, RSA500, and RSA600 Series (USB RTSAs) will serve to support applications such as EW spectrum monitoring, deep-data signal analysis, RF sensor SIGINT, high-mix/ low-volume manufacturing programmatic control and test, and custom SATCOM transmitter range testing,” he said. “These instruments are used to monitor RF signals over a large field of operation. In the military, such as on a ship or on an airfield, the ability to network multiple RTSAs can be a significant benefit.”

Odhner elaborated on real-time spectrum analysis, saying real-time spectrum analyzers like the RSA7100B have an IQ streaming capability. “IQ data, also called quadrature signals, contain complete information about the RF spectrum,” he said. “This means that you can re-create a captured signal in time or frequency domains, even at the same time. This gives, for example, radar design engineers the ability to simultaneously analyze the time domain pulse structure of a radar signal while characterizing the phase noise or drift of their system.”

He added that the capabilities are tied to Tektronix’s SignalVu-PC and SourceXpress software offerings. “SignalVu-PC facilitates real-time, multidomain display and analysis, while SourceXpress allows quick modification of IQ data for output on RSAs,” he said.

Brian Walker, senior RF design engineer at Copper Mountain Technologies said the company offers a range of vector network analyzers from 9 kHz to 110 GHz, with compatibility for use of third-party frequency extenders up to 330 GHz. “The biggest advantage of a USB VNA is that it doesn’t lock the user into a built-in computer that is already outdated and expensive to replace since the replacement can only be done by the analyzer’s manufacturer or their authorized service center.”

He said, “unlike the conventional VNA, with USB instruments, the user can easily upgrade the external PC as needed to keep it up to date and secure.” Walker added the company’s VNAs find use in materials testing of radome materials, testing of phased array antenna systems, distance to fault measurement of avionics or shipboard RF conduits, antenna VSWR testing, cavity filter tuning, and other RF measurement applications.

Data acquisition

Rule added that multiple 7000 systems (up to 4,096 channels) can be connected on a single Ethernet LAN, and each channel can sample at up to 200 ks/s while maintaining 1-μs synchronized sampling across all channels. “Series 7000 16-channel enclosures are designed for installation in wind tunnels, engine test stands, and other facilities where it is desirable to locate the DAS on or near the test article, reducing installation and cable costs while improving signal quality and reliability. Temperature compensation, high gain, and 24-bit A/D provide a high-accuracy and high-resolution DAS that will perform across a wide temperature range at better than 0.05% accuracy.

Stratton continued, “Weiss Technik is the leader in providing LOW GWP (Low Global Warming Potential) refrigerants in test chambers. All Weiss Technik chambers use R449-A refrigerants with a 64% lower GWP value, which is great news for the environment and helps support both corporate and federal sustainability programs. Weiss Technik has redesigned and extensively tested its refrigeration systems to make sure that the use of R-449A comes with no loss of performance and reliability.”

Switching technology

“In terms of addressable markets, our uniqueness stems from the number of choices available, especially the density of our products, as defense and aerospace applications tend to be high channel-count,” Stasonis said. “For example, our 40-558 matrix, which offers 40% higher switching-density than our competitors, is an attractive product for those applications needing high channel-counts. Also, our willingness to create new designs to address niches in the Aerospace market is a special differentiator.”

In addition, Stasonis said, “Logistics and sustainment costs are important to depot repair—they need a quick and easy way to find faults in a test system. Fortunately, we have robust in-situ self-test applications which makes these requirements much more efficient – In the battlefield and at the depot.”

Alderson said that to help control budgets, USC manufacture modular hardware where customers can begin with a smaller configuration and expand as more funding is acquired, an approach taken with the BS1553F, which can be configured from 8x8 to 64x64 in increments of eight ports in symmetrical or asymmetrical configurations. “Also, we have a constant product improvement corporate strategy within our ISO 9001-2015 Quality Management System (QMS),” he said. “With this strategy, we regularly review product designs for improvements in performance, speed, cost reduction, better manufacturability, and additional new features.”

As for applications, “We serve nearly all Major Range and Test Facility Bases (MRTFB) across the nation as well as satellite ground stations, Amy, Navy and Airforce Research Laboratories,” Alderson said. “Also, we serve a large majority of defense contractors and government agencies including NOAA, NASA and the newly formed US Space Force.”

Leitner said a Menlo Micro MEMS switch can be thought of as a “mechanical transistor,” hundreds of which can be fabricated on a single wafer with a process scalable and optimized for power and frequency. “The extremely low ‘on-resistance’ and ‘off capacitance’ result in ultralow parasitics that enhance the tuning characteristics of the filter,” he said. “Another aspect is the switch reliability, which is a key differentiator for aero-mil applications and systems. The switches have been tested and pass the rigorous environmental IEC and MIL-STD requirements, and are specified at over 3 billion cycles of operation.”

MIL-STD-461 and MIL-STD-464 testing

“As always, the biggest challenge facing radiated susceptibility testing is the 100-MHz to 200-MHz frequency range, where antennas often have negative gain,” Landers said. “This can result in severe impedance mismatches which lead to low delivered power and high reflected power. Fortunately, our amplifiers can withstand the results of these heavy mismatches with no damage to the amplifier output.”

To meet these challenges, Landers said, AR designs systems working directly with customers to develop a solution to meet their needs. “AR is unique in that we give options to the customer,” Landers said. “Whether it be using higher-power amplifiers with lower-gain antennas, or a lower-power set of amplifiers with higher-gain antennas, we work directly with the customer to stay within their budget and still meet their field requirements with room to spare. We can also incorporate a customer’s existing equipment into our system for seamless integration and operation.”

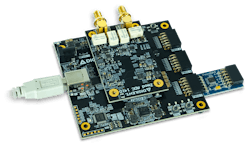

Embedded ecosystem

Wadkins explained that an onboard USB controller provides interfacing and programming of the FPGA through both JTAG and UART with only a single connection. He added that an onboard QUAD-SPI flash stores the FPGA configuration between power cycles.

Greenfield continued, “AcroPack I/O modules are a hybrid between the popular but disappearing IndustryPack modules and mini-PCIe cards that often lack the durability required for mil/aero applications. AcroPacks support a modern PCIe interface that also includes a down-facing connector like IndustryPacks that securely routes I/O signals through a carrier card to field connectors without loose internal cabling.”

Power sources

“Pacific Power Source’s new LMX Series linear AC power sources meet the need for low noise, low distortion, high-quality AC power not available from general-purpose switch-mode AC power sources,” vanEijkelenburg said. “With both single- and three-phase models covering a range of power levels from 500 VA to 30 kVA, these linear AC sources offer high-performance programmable power with modern control interfaces like LXI-compliant LAN and USB. Pacific Power also offers a broad library of power test-compliance software suites for airplane equipment, including MIL-STD 704 and RTCA/DO160, as well as manufacturer-specific test standards for Airbus and Boeing.”

Kikusui offers AC power supplies (PCR-WE Series) through parallel operation can support outputs to 144 kVA; the frequency can extend to 5 kHz, the spokesperson said, adding that it can also serve as a DC supply that can be used in power-supply fluctuation test. “The high-speed amplifier bipolar power supply (PBZ Series) can simulate a load connected to the DC line of the battery and DC/DC converter using the actual waveform data acquired in the field for evaluation and testing.” A built-in waveform generator can be used for noise superposition and low-voltage power supply voltage fluctuation test.

Chassis and connectors

He added, “For smaller testers Hartmann Electronic is minimizing the needed rack space for a few PXIe or PXI instruments to just one unit height offering a 6-slot horizontal chassis with one system slot, one PXI slot, and four hybrid slots in Gen3 connectivity.”

In related news, Justin Moll, vice president of sales and marketing, Pixus Technologies, said the company is offering a new product to address the trend of aerospace apps starting to use SpaceVPX (VITA 78, etc.). The new product is an OpenVPX chassis platform that supports both 160-mm deep (standard OpenVPX) and 220-mm deep (SpaceVPX) boards. The open-frame chassis features up to four slots at 1.0-in. pitch of each board depth type. The modular enclosure allows various board pitches to be used at 0.2-in. increments. Card guides support both air-cooled boards and conduction-cooled boards, with wider 220-mm-deep card guides to support extra-thick SpaceVPX conduction-cooled boards per VITA 78.

Finally, Rosenberger reported that it provides a comprehensive portfolio of high-reliability interconnect components and devices qualified for aerospace, security, and defense applications. Products are available complying to the MIL-PRF-39012 standard, the DIN EN 9100 standard, or the ESCC (European Space Components Coordination). Specific products include RF coaxial components, microwave components and cable assemblies, RF test and measurement products, and fiber-optic connectivity components.

Trends and challenges

“The trend we see is that maintainers are seeking easy to use, sustain, and deploy test sets that overcome the obsolescence and multiple large box test sets found on the flightline today,” said Sargeant of Marvin Test Solutions. “They define obsolescence as test sets that do not functionally test the systems that enable the employment of Smart weapons, that do it only with very long set up and tear-down time coupled with excessively long test times. In addition, cybersecurity must be built into all test sets that connect to the aircraft, armament, or munitions.”

Challenges extend from test setup time to security issues. According to Sargeant, maintainers face using multiple large-box test sets that take several airmen to carry to the flightline, and consume large amounts of time to set up, tear down, and run tests on the flightline. “These large, slow test sets compound the problem of the reduced number and lower experience levels of maintainers found in squadrons today. All levels of maintainers are faced with an ever-growing number of cyber threats, therefore, they are searching for cybersecure test sets to combat the threat. They are also dealing with more classified systems than in the past, so it is important to have devices that can protect sensitive material.”

Butler at NI cited many trends affecting NI’s aerospace and defense customers. “One trend in particular being driven from an enterprise level in these organizations is digital transformation,” he said. “Through digital transformation initiatives, these customers are looking to modernize both their products and their processes to enhance quality, reliability, efficiency, and profitability—and ultimately improve mission readiness. This trend is the result of a convergence of digital technologies, and promises to revolutionize the way companies design, manufacture, and service their products.”

Butler continued, “There are many challenges our customers face, including increasing asset complexity, continued schedule and budget pressures, and staying competitive in a contested industry. These general challenges also create specific difficulties for test managers and their teams, which is where NI can help.”

McCarthy at Rohde & Schwarz cited the commercialization of space, or NewSpace, as an interesting trend. “With the recent return to space of NASA astronauts on board a commerciall- funded rocket from SpaceX, it is clear that the military and aerospace industries are attempting to leverage commercial technologies in space,” he said. “From a standpoint of RF and microwave communications testing, this also involves the desire to utilize commercial communications standards in NewSpace, for secure and globally-available networks.”

McCarthy added that commercial communications standards being developed in parallel include the 3GPP work item on non-terrestrial networks (NTN). “NTNs can provide a tactical battlefield or global coverage of secure networks, and they have three areas of concerted development in the defense industry: low-Earth orbit (LEO) satellite systems, high-altitude platform stations (HAPS), and unmanned aircraft systems (UAS),” he said. “Of these three investments, some of the most promising and popular innovations present in the emerging commercialization of space, are the investments in the LEO constellation networks. To make NewSpace viable communications networks that utilize commercial standards, engineers must solve the rising challenges and complex antenna problems.”

Friedrich at Keysight commented on Keysight’s threat simulation/emulation solutions for electronic warfare. “In terms of electronic warfare, the electromagnetic spectrum environment continues to grow more dynamic, reflecting new sources of threats and the growing presence of innovative technologies that are more intelligent and adaptive,” she said. “Customers find it increasingly challenging to keep pace with the technology shifts in the EM spectrum, as legacy systems do not present a realistic and accurate picture of the new threat environment. Simply put, they cannot identify and respond to threats quickly enough or adequately simulate how those threats may change behavior to see how their EW systems will respond.”

Walker at Copper Mountain Technologies commented on security from the perspective of a vector network analyzer manufacturer, calling USB VNAs a better fit than traditional instruments. “Taking traditional network analyzers in and out of secure environments is a lot of work, requiring removable hard drives, data-purging procedures, and oversight over those data-purging procedures. With USB VNAs the computer that stores and processes the data is separate from the measurement module, so, as long as the computer stays in the secure area, all data concerns are eliminated, and the data measurement module can easily move between laboratories and sites. Our measurement module has only volatile memory, so no data is retained, and the separate PC can be made secure following standard security protocols.”

Anritsu has noticed two main trends, according to Summers. First, “Deployed systems are continuing to be more technical, along with the tools used to maintain them. This has created a need for technical test tools that analyze complex signals and technologies, yet are easy to operate,” he said. “The second trend is that commercial communication technologies are becoming more commonplace in MIL/aero-deployed networks.”

Summers cited challenges related to signals intelligence (SIGINT) and electronic warfare (EW), which require precise test and measurement equipment, such as spectrum analyzers, to operate according to specification in demanding environments. “Test ranges and government installations require a complete understanding of signals generated internal to the facility, as well as those generated from the outside that enter the facility,” he said.

Rule at Pacific Instruments identified trends toward large-scale systems and structure testing requiring an integrated data-acquisition system capable of supporting multiple types of sensors, wide range of sample rates, filtering schemes, modularity and expandability. “The ability to operate the whole system as one system or to split it into multiple subsystems each dedicated to a specific test is desirable,” he said. “For smaller scale tests like jet-engine, hydraulic, power, or transmission subsystem tests, many military and aerospace facilities are evaluating and moving toward a distributed data-acquisition system architecture. The ability to utilize a network of small data-acquisition systems located as desired and linked together as one large system is advantageous in many applications instead of the standard approach of having a single large data-acquisition system in the control room.”

Rule noted that the time and costs of setting up a data-acquisition system can be high. “Wiring and cabling the UUT to the DAS is expensive in terms of labor and hardware cost, especially when the DAS is located far away from the UUT,” he said. “Considerations such as noise reduction, EMC, and signal attenuation increase the complexity and cost even more,” especially for facilities that need a quick turnaround between test articles, such as jet-engine testing facilities. “By locating the data-acquisition system(s) closer to the area of interest or on the test article, a significant savings in cabling costs, installation time, and labor can be realized with increased immunity to interference and system reliability.”

Stratton at Weiss Technik commented that defense and military products must meet stringent testing and safety requirements and comply with many testing standards. “The products are exposed to many elements which need to be accurately replicated through thermal shock, temperature cycling, and more,” he said. “Additionally, products must also meet many MIL-STD specifications and have safety features in place for the users. For the testing of hazardous substances, specific Class and Division ratings and explosion resistant (ER) requirements can be met to ensure the highest level of safety.” He added that Weiss Technik offers many advanced test chambers and technologies to meet many industry testing requirements. “Our chamber interior construction design meets the Class and Division ratings needed for many defense and aerospace testing applications,” he said.

According to Stasonis at Pickering Interfaces, “The advances in AI and machine learning will likely mean more HILS applications to test for all possible circumstances, whether it is hardware, firmware, or software testing to prove that the ‘lessons learned’ are correct. We are also seeing a drive for smaller test systems to bring better support to the battle front.”

Stasonis emphasized that the product life/availability of test gear should be as long as possible. “We publicly state on our web site that switching products are available for 15 to 20 years and sometimes longer,” he said. “For defense applications that are reaching end-of-life—for example, VXI instrumentation—we offer migration paths from VXI switching to PXI. In order to keep our product families supportable in the long haul, we have gone through projects where we design out obsolescence in our products—ensuring that newer designs are form/fit/function the same compared to older models.”

Regazzi at Giga-tronics commented on trends from both a business and technology perspective: “From a business perspective, it appears the years of sequestration are behind us and there is funding available for new activities rather than just for a continuation of previously committed programs. From a technology perspective, the demand has finally arrived for test equipment to process signals with instantaneous bandwidths in the GHz range. It’s not easy to accurately synthesize signals from parameters extracted from flight recordings or to recreate a realistic electronic scenario that radars and countermeasure equipment will experience in actual combat.”

Averna over the past year has identified two trends that have stood out in MIL/aero test. “The first is a result of the many acquisitions that have transpired within the industry. Now we are seeing companies investing in streamlining the inherited source code and multiple platforms. The goal is to standardize older code and optimize it for the sake of longevity,” said Anderson and Lingafeldt. “Separately, we have also seen increased connectivity testing for Iridium network-based aircraft communication modules. With the contribution Iridium Communications has made towards reliable communications coverage anywhere in the world, the integration of their modems and technology into mil-aero solutions continues to grow.”

They continued, “The main challenge we are seeing our customers face is simply meeting demand quickly enough. The work within the industry in the United States has not been affected by the global situation and it is simply a matter of meeting deadlines. Outsourcing is becoming more prominent across the board.”

According to Wadkins at Digilent, “The earlier standards for embedded computing often used in MIL/aero applications, such as PC/104 and VME, required CPU cards, single-board computers (SBCs), and I/O to be specifically compatible with the connectors and mechanical features specified by those standards. As application demands continue to advance, vendors have released an ever-increasing variety of embedded PCs and industrial I/O in myriad enclosure types. This presents a challenge for embedded systems that are built to an existing standard and a parallel bus. As such, the demand for serial buses, particularly USB for its already widespread adoption, has increased within the embedded PC world.”

“The US Army has awarded in excess of $3B in contracts for a new generation of manpack and handheld radios with enhanced performance over the existing first-generation software-defined radio technology,” said Leitner at Menlo Micro. “These ‘second-generation’ radios are required to have improved digital modulations, waveforms, and data rates, while supporting existing milcom systems like SINCGARS. The largest share of these new contracts will be for field handheld radios, and the additional modulation and systems schemes will require enhanced RF performance and improved integration in terms of size, form-factor, and ruggedness.”

The increasing set of milcom specifications (advanced modulation schemes, systems, and data requirements) require performance and scalability for frequency and power, Leitner said, adding they must be mass-produced to meet MIL-STD ruggedness and reliability. “Aero-mil customers have come to the realization that these criteria can often not be met with a single solid-state process and technology, and so there is more emphasis being placed on the investigation and use of alternate technologies, like RF MEMS, to meet their requirements,” he said.

According to Greenfield at Acromag, “Customers are fighting component obsolescence issues and the need for higher performance within size, weight, power, and cost (SWaP-C) limitations.” He commented, “Many customers continue to migrate from VME-based systems as boards go end-of-life. The alternative is usually a rugged server with PCIe expansion cards, or a rugged small-form-factor embedded computer with mini-PCIe modules.”

Kikusui provides power supplies for military/aerospace applications, and a spokesperson for the company said the demand for power supplies exceeding 100 kW is increasing as the electrification of MIL/aero applications expands. “There is also a demand for variable frequency, and there is a demand for an AC power supply that can output frequencies of 1 kHz or higher,” the spokesperson said, with applications including the evaluation and test of VFAC (variable-frequency AC) generation systems. Consequently, variable-frequency outputs are required in addition to 400-Hz outputs. Also required is bidirectional, regenerative operation for battery discharge test.

vanEijkelenburg at Pacific Power Source commented that trends evolve slowly in aerospace applications due to regulatory and FAA requirements requiring extensive certification cycles. “However, there is a growing trend towards replacing hydraulic systems with electrical systems in an effort to reduce lifetime maintenance costs,” he said. “Some of these are DC-power-based coupled with battery-storage and energy-recovery techniques aimed at reducing overall energy use.”

vanEijkelenburg added that MIL/aero customers must support existing test platforms much longer than originally planned. “Test platforms are not being replaced in a timely manner due to budget constraints,” he said. “This is shifting increased focus from developing new test systems to upgrading and supporting existing, aging testers. As a result, T&M equipment manufacturers are asked to support their products for long periods of time—far longer than would be the case for commercial aviation customers. In the case of Pacific Power Source, several of our programmable AC power sources have been deployed in these ATE systems for 30+ years, and we continue to support these with service, spares, upgrades and in many cases new production units.”

REFERENCE

1. Nelson, Rick, “From the Simulation Environment to the Flightline,” EE-Evaluation Engineering, February 2020, p. 10.

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.