Given the recent recalls of Li-Ion batteries used in certain mobile computers from Dell and Apple, batteries may soon become the highest-profile components in the minds of consumers shopping for those systems. Whereas user transparency may once have been a fundamental design goal in portable systems, power designers may soon be concerning themselves with brandable features for battery safety that resemble those used to indicate high-performance in mobile computing, such as Intel’s Centrino brand.

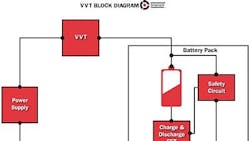

One technology specifically designed to improve the safety of rechargeable Li-Ion batteries is the recently announced Virtual Voltage Termination (VVT) technology from International Components Corporation (ICC). The technology is designed to safeguard against potentially hazardous battery charging conditions, including thermal runaway, which can lead to overheating and fire. An increased susceptibility to that particular hazard was the motivation behind the recent battery recalls.

The basic charging profile of Li-Ion batteries consists of four charging stages, which occur in the sequence of trickle, constant-current (CC), constant-voltage (CV) and termination. (A more detailed description of this process is provided in “Charging Li-ion Batteries for Maximum Run Times”, by Scott Dearborn of Microchip—PET, April 2005.) VVT actively measures the open-circuit voltage (OCV) of the battery cells within a battery assembly throughout the constant-current stage of the charge cycle.According to Michael Davis, Executive Director of Global Marketing and Sales, conventional constant-current/constant-voltage (CC/CV) chargers simply measure the voltage at the battery's terminals without regard to the charge state of the internal cells. This can result in extended, incomplete, or unsafe charging.

According to Davis, the inspiration for VVT came during the analysis of data from a Li-Ion charging system designed to maintain ±50 mV across the battery terminals. The instrumentation that collected the data showed the battery voltage measured across the terminals was different from the battery voltage sampled at the input of the system’s ADC. This was attributed to voltage drops developed across traces carrying high current.

Davis stated the microcontroller performing the analog-to-digital conversion in that system was also controlling the charge current to the battery, so an algorithm was developed that removed this current prior to each sampling of the battery voltage by the ADC. Opening the circuit would have also negated errors caused by series circuit elements such as safety circuits, connecting straps or dirty contacts. ICC’s VVT technology presently achieves better than ±10-mV measurement accuracy on a single-cell Li-Ion battery.

Once the battery cells’ OCV reach a set voltage (4.1 V or 4.2 V per cell), the VVT algorithm switches to CV mode and measures current to a selectable termination level (C/10 or C/20) based on the application. The key aspect of VVT is that the cells are actively engaged during CC mode and can stay in CC mode for the majority of the charge cycle, depending on the charge rate. In CV mode, the algorithm is engaged with the cell voltage, current, and temperature to insure safe charging and charge termination.

The end-of-charge error (CV mode) still exists in the VVT enabled charger, but the time spent in CV mode is minimized when compared to conventional chargers. Thus, a VVT-enabled charger can charge in the same time as conventional chargers with 25% to 35% less current. This lowers battery stress and heat, and increases battery charging accuracy and safety.

The firmware implementing VVT technology provides a second layer of protection that compliments the safety ICs typically found in conventional battery charging systems. The microprocessor executing the VVT algorithm is actively engaged with the cells in the pack during charging without introducing additional costly hardware. In essence, the technology prevents potentially hazardous battery charging conditions while maximizing the battery’s performance through the life of the device.

VVT technology works with all major Li-Ion batteries. Recent recalls of mobile computer batteries have raised safety concerns, and it probably will not be long before the technology is thoroughly evaluated by OEMs. While this process would be a major task, it would dwarf in comparison to the true cost of failing to acknowledge and address the concerns of consumers about battery safety.