Coatings make engines more efficient

A new coated piston for gasoline engines called an EcoTough-coated piston reduces fuel consumption up to 0.8% compared to conventional piston coatings. Developed by Federal-Mogul Corp., the piston is compatible with existing and advanced cylinder bore finishes and can be introduced in volume engine production as a running change.

The key behind the EcoTough-coated piston technology is the composition of the coating, which is comprised of solid lubricants, including graphite, molybdenum disulfide (MoS2) and carbon fiber. In applications requiring additional protection -- as with a rough cylinder honing structure -- the EcoTough-coating is thicker than the conventional piston coating. Federal-Mogul says the technology suits high-volume manufacturing and is less sensitive to pre-treatment process variations. The EcoTough-coated piston also fulfills the most stringent environmental standards and contains no toxic solvents.

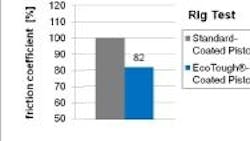

In laboratory testing, EcoTough-coated pistons show an 18% piston friction loss reduction and an improvement of up to 3% in entire engine parasitic loss. Engine bench tests confirm a fuel economy benefit of 0.4 to 0.8% in normal driving conditions. In wear resistance testing at full load and after 50 cold-start cycles, EcoTough-coated pistons wear less than conventional piston surfaces in contact with the cylinder.

EcoTough-coated pistons are currently in production, having recently been introduced on a high volume vehicle from a major European manufacturer.