Automotive Ambient Lighting: How to Tackle Color Drift and Simplify Design

As autonomous-driving capabilities develop, the vehicle interior will evolve to focus more on comfort, information, and communication. As a result, in-vehicle ambient lighting is becoming much more than just lighting and decoration.

Today’s lighting systems are expected to be a customizable and adaptable part of smart cockpit applications to enhance the driver experience. And they must maintain precise color accuracy, thermal stability, and communication robustness over several years of continuous operation. Dynamic ambient lighting options could display relevant information to the driver, such as incoming calls or notifications from navigation or advanced driver-assistance systems (ADAS).

This new trend brings several technical challenges for automotive designers, particularly when implementing RGB or RGBW lighting networks across distributed vehicle platforms. One of the most persistent of these is managing LED color drift due to thermal effects and aging.

At the same time, the need for space-efficiency when integrating lighting control, diagnostics, and in-vehicle networking, especially over the Local Interconnect Network (LIN), is driving the transition away from discrete component designs. In their place are more integrated approaches, which reduce complexity and ensure electromagnetic-compatibility (EMC) compliance.

The Color Drift Challenge

RGB LEDs naturally exhibit wavelength shifts as junction temperature rises, leading to subtle color changes. For example, red LEDs might commonly shift by 1 to 2 nm per 10°C,1 but this variation would be visually noticeable in mixed-color scenarios. Over time, LED aging can compound the problem. This affects individual channels at different rates and leads to noticeable color inconsistencies, especially in edge-lit panels or accent strips.

Compensation strategies have tended to rely on manual calibration or lookup tables based on ambient temperature readings. However, these approaches fall short in constantly changing environments. As such, real-time, closed-loop color compensation is needed. And this should be based on the actual operating conditions of the LEDs themselves.

A more effective approach involves sampling the forward voltage (Vf) of each LED channel differentially, combined with direct temperature sensing near the LED die. Vf has a known negative temperature coefficient, making it a reliable proxy for junction temperature, especially when measured under low-current conditions to reduce self-heating.

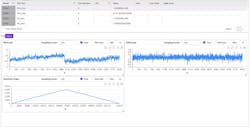

By integrating a high-resolution analog-to-digital converter (ADC) with temperature- and voltage-sensing circuits directly into the LED control IC, the system can dynamically adjust pulse-width modulation (PWM) or analog current drive to counteract drift. This allows for continuous correction across the full operating range, extending LED life and preserving the intended color mix across the vehicle’s lifetime (Fig. 1).

Dimming Precision: Why Bit Depth Matters

Smooth dimming isn’t just about comfort; it's critical for accurate color rendering and transitions. Though standard PWM techniques often use 8- or 10-bit resolution, systems targeting high-end lighting effects would benefit significantly from 16-bit PWM combined with a lower-bit analog dimming function. The higher PWM resolution allows for more granular intensity control, while analog dimming reduces quantization artifacts and improves linearity, especially at low brightness levels.

For applications like mood lighting or nighttime illumination where subtle changes are more noticeable, these enhancements are essential for avoiding visible flicker or uneven transitions.

LIN Communication: From Bottleneck to Enabler

Ambient light modules often rely on the LIN bus for communication with the vehicle’s main controller. However, the number of nodes in vehicles is rapidly increasing — from doors and footwells to charging ports and center consoles — and managing the nodes and their firmware updates is becoming a logistical challenge for the network.

>>Download the PDF of this article

A common task that consumes time and resources on production lines is manual LIN address configuration. Implementing auto-addressing through bus-controlled logic and electrically erasable programmable read-only memory (EEPROM) storage can eliminate human error, reduce assembly time, and allow for true plug-and-play modularity.

In addition, supporting Unified Diagnostic Services (UDS) directly from ROM eanbles in-field software updates without occupying main flash memory. It offers a great advantage for maintaining firmware over a vehicle’s lifecycle, especially in over-the-air scenarios.

Adding to the complexity, lighting modules embedded in doors or near windows must contend with harsh electrical and thermal environments. To ensure system reliability, compliance with CISPR 25 Class 52 for electromagnetic compatibility is becoming a standard requirement for these components. Designers should look for LED driver solutions that internally implement spread-spectrum clocking, fault diagnostics, and thermal-shutdown features to reduce the burden of external circuitry.

Robust protection on power inputs and LIN transceivers, such as reverse-voltage tolerance and load-dump resilience, is also essential for surviving real-world automotive conditions without frequent failures or the need for complex protection networks.

From Integration to Intelligent Control: Evolving Ambient-Lighting SoCs

Traditionally, RGB lighting modules were implemented using a discrete microcontroller, separate LED drivers, external LIN transceivers, and various passive components. While functional, this approach increases the overall footprint, BOM cost, and design complexity. In addition, challenges emerge in achieving EMC compliance with multiple high-speed switching elements spread all over the PCB.

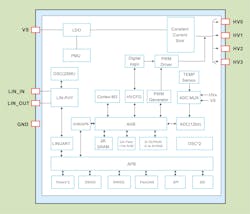

An alternative approach would be moving to an integrated SoC approach solution that combines the microcontroller, LED drivers, transceivers, and temperature sensors in a single package. This not only reduces component count, but simplifies certification, improves signal integrity, and frees up board space for thermal management or mechanical design flexibility.

Similarly important for improving system flexibility is built-in UDS support, which allows for software updates directly without requiring bootloader programmed in flash memory.

These are starting to enter the market. For example, NOVOSENSE Microelectronics' NSUC1500-Q1 combines an Arm Cortex-M3 MCU, a LIN transceiver, four high-precision LED drivers (up to 64 mA each), and temperature/voltage sensing for real-time color compensation.

Such SoCs can be used alongside a linear LED driver, such as the NSLxxxxx portfolio, to deliver scalable, low-noise current control across multiple channels (16 in the case of the NSLxxxxx) in the implementation of high-density lighting modules (Fig. 2).

Together, such solutions can significantly reduce the bill of materials, wiring complexity, and development time while enabling smooth dimming, accurate color rendering, and robust diagnostics. Thus, they can deliver reliable performance across a wide temperature range in demanding automotive interiors.

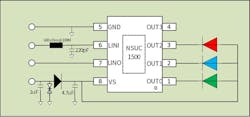

This type of solution makes it easier to scale ambient lighting across vehicle platforms. Engineers can use the same core design for a three-channel door light or a 12-node dashboard module simply by adjusting firmware or stacking driver outputs, making them ideal for modular lighting architectures (Fig. 3).

Designing for Diagnostics and Fail-Safe Modes

Automotive lighting is increasingly subject to functional-safety requirements, especially when linked to driver awareness or UX-critical systems. A modern ambient-lighting controller should not only detect open/short LED conditions, but also log and report them through LIN. EEPROM-based configuration and fallback behaviors, such as default colors or brightness settings in case of MCU failure, can also ensure graceful degradation instead of total module blackout.

Designers should implement fault flags for supply undervoltage, LED current anomalies, and temperature thresholds. All of these can be processed locally or reported upstream depending on system needs.

Automotive ambient lighting is growing into a feature that will play an important role in vehicle branding, driver awareness, and overall user experience. To meet the high expectations of today’s OEMs and end-users, engineers will need to balance the demands for visual quality, thermal robustness, and EMC performance with ever-present cost and space constraints.

By adopting real-time sensing, smarter communication strategies, and integrated control architectures, engineers can deliver solutions that aren’t just visually stunning, but also reliable, scalable, and production ready.

References

Quantum Dot Based White LEDs for General Illumination, LED Professional.

CISPR 25:2021, International Electrotechnical Commission.

>>Download the PDF of this article

About the Author

Feng Gao

Feng Gao, Technical Marketing Manager, NOVOSENSE Microelectronics

Feng Gao joined NOVOSENSE in 2022 as technical marketing manager, responsible for specific standard processor products. With more than nine years of experience in semiconductors, he has profound knowledge about MCUs and motor drivers. Feng holds a master's degree in Control Engineering from Shanghai JiaoTong University.