Members can download this article in PDF format.

It’s well-known that advanced packaging will separate the haves from the have nots in the race to effectively run artificial intelligence (AI), connect Internet of Things (IoT) devices, and handle 5G networks. It’s also common knowledge that progress in advanced packaging will require a parallel evolution in lithography technology, making it more cost-effective, scalable, and precise.

Traditionally, lithography equipment has projected light through a mask onto a very flat surface coated with a photosensitive material. These masks are typically made of glass or quartz and coated with specific materials that block light from passing through, while the uncoated parts remain transparent and allow light to pass through.

When UV light is shone onto the mask, the light that passes through hits the photoresist, curing the pattern established by the mask. One challenge with this technology is that a mask can’t change the pattern. Rather, a new mask must be fabricated to change printed features.

Going Maskless

But by eliminating masks, assembly equipment manufacturers can create digital lithography systems that print the high-resolution patterns needed for the next generation of high-computing solutions — without the significant expenses associated with designing, manufacturing, and managing physical masks.

Among other advantages, this provides a more efficient and flexible lithography solution to manufacture the complex, modular components known as chiplets. Chiplets combine the best components for specific tasks and link them efficiently in applications such as data centers and autonomous driving.

For those unfamiliar, digital light processing (DLP) technology facilitated the transition from film to digital projection in cinemas. The fast-switching microelectromechanical system (MEMS) modulates light using a digital micromirror device (DMD) (Fig. 1). Each micromirror has a reflective aluminum surface that can be just a few microns wide.

A DMD steers light by electrostatically deflecting or switching each mirror up to thousands of times per second. To accomplish this, a 1 or 0 is loaded into a memory cell beneath each mirror, which activates electrodes that control whether the mirror is switched to an on or off state.

Using DMDs for Photolithography

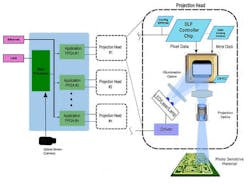

TI's DLP technology enables advanced packaging by using a DMD as a programmable photomask to create precise, cost-effective, and high-resolution lithography without traditional physical masks. This maskless approach increases throughput and yield as well as reduces defects (Fig. 2). It further allows for real-time design adjustments and corrections without waiting for new masks to be created.

TI’s DMD has up to 8.9 million microscopic mirrors that can be individually tilted on or off to precisely control light in real-time. When UV light is shone onto the DMD, the micromirrors in the DMD tilt on or off to modulate the light. It forms a pattern that’s projected onto photosensitive material, creating a circuit design that can include features such as traces, vias, and solder masks.

Using DLP technology, if a pattern needs adjustment, engineers can immediately make changes and implement them by updating a software file instead of creating a new mask. DLP technology thus can continuously adjust the pattern to match the material’s actual surface conditions. This accelerates innovation cycles and reduces wasted materials

DLP991UUV: Enabling Cost-Effective and Adaptable Precision

DMDs like TI’s DLP991UUV are spatial light modulators (SLMs) made of millions of individually addressable micromirrors, or pixels. These DMDs provide control across a wide range of wavelengths from 343 to 2500 nm and sizes from 0.1 to 0.99 inches diagonal, allowing for flexibility in system design.

The high-resolution DLP991UUV DMD modulates the amplitude, direction, and/or phase of incoming light. It offers the highest resolution and the fastest processing speed in the TI portfolio with up to 110 Gpixels/s. The streaming nature of the DMD, and the DLPC964 controller used with it, make the device an exceptional option for high-speed continuous data streaming in direct imaging applications.

The DLP991UUV DMD, designed to support the advanced packaging market, can be tailored to optimize photoresist performance. This DMD enables real-time corrections with maximum exposure speeds and panels per hour. Thanks to its high resolution, equipment manufacturers can maximize throughput and increase exposure area.

TI also offers the DLPC964 Evaluation Module (EVM) reference design to facilitate faster development of the DLPC964 controller architecture in support of the DMD. This platform receives high-speed bitplane data from an external source through the AMD Aurora 64B/66B interface. It formats the bitplane data before loading the data into a DLPLCR99EVM or DLPLCR99UVEVM for display on the DMD.

Conclusion

Because advanced packaging systems print patterns on materials that can have variations in typography, which can occur on a surface that’s not completely flat, maskless lithography is becoming a cost-effective and adaptable option for equipment manufacturers.

DLP technology continuously adjusts the pattern to match the material’s actual surface conditions. And its real-time adaptability ensures that patterns are printed precisely, even when the surface beneath them isn't perfectly level.