Bluetooth without Batteries? Atmosic Technologies Says It Can Be Done.

David Su's last job was vice president of analog and radio frequency engineering at Qualcomm, and before that he spent more than a decade at Atheros Communications. That was where he met David Nakahira and Masoud Zargari, two of the original members on the Atheros engineering team. Qualcomm hired them all following its 2011 acquisition of Atheros, and all three left within months of each other in 2016.

“And we’re not sick of each other yet,” Su told Electronic Design.

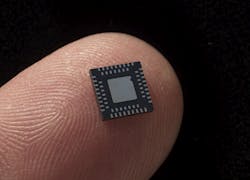

Su has since taken over as chief executive officer of Atmosic Technologies, the startup he founded with Nakahira and Zargari. The company plans to start by selling Bluetooth 5 chips for applications that need to send small amounts of data over long distances without burning through their disposable batteries. Specifically, the startup is targeting wearables, beacons, keyboards and other devices that generally communicate infrequently.

Atmosic Technologies said that its CMOS-based SoCs consume 10 times less power than anything else available on the market. That allows them to run indefinitely on an energy harvester that can completely replace batteries in factory and consumer electronics using Bluetooth. Unit shipments of Bluetooth chips used in Internet of Things endpoints are projected to grow from 680 million units to 1.54 billion in 2021, according to ABI Research.

“We started from a clean slate,” Su said. “We went through every RF block carefully”—the modem and the wireless front end—“and even though there was no one-size-fits-all solution, we were able to lower the power consumption by ten times through circuit level techniques.” The company will have to compete with major Bluetooth chip suppliers, including Texas Instruments, Cypress, Dialog and Nordic Semiconductor.

The company is using other strategies to curtail system power. The new devices are capable of on-demand wakeup, which allows the transmitter to remain in sleep mode while listening for wireless signals from other devices that wake it up. “Most lower power devices do not need to be communicating all of the time,” Su said. “Most of the time they are in standby mode. So we asked if we could make a standby mode that consumes almost no power.”

The power requirements are so minimal that the chips can be powered with harvested RF energy. But instead of harvesting ambient energy, the chips require dedicated power supplies, such as wireless transmitters embedded in a light bulb. Atmosic Technologies said that their energy harvesting antenna can generate single-digit milliwatts as long as it remains close enough to the power supply with 30 to 40 percent efficiency, excluding RF path loss.

Using energy harvesting, the new chips can send information at one megabit-per-second while consuming around the same amount of power as near-field communications (NFC). Another benefit is longer range than NFC, which can only cover about 20 centimeters. Not every electronic device using Bluetooth needs to send large amounts of data, so reducing the data rate allows them to send messages further.

San Jose, California-based Atmosic is targeting applications, like wearables, that only periodically need to transfer data to other devices, like a smartphone. The chips could also be embedded in Bluetooth beacons used for indoor positioning and asset tracking in factories and buildings. They could also be used to enable mesh networking, in which devices communicate with the closest device in the network to relay messages over a wide area.

By 2022, these kinds of applications are projected to account for 30 percent of Bluetooth device sales, not including smartphones and personal computers. "The time and money to maintain this magnitude of battery-dependent devices may well limit the potential of the connected Internet of Things,” said ABI Research analyst Andrew Zignani, adding that Atmosic Technologies “may solve some of the key pain points.”

The company has raised $21 million of venture capital funding from Sutter Hill Ventures, Clear Ventures and Walden International, since it was founded in 2016. Their chips—one with the internal energy harvester, another without it—are currently available to customers as samples. Both products are expected to enter volume production in the second quarter of 2019, according to vice president of business development Srinivas Pattamatta.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.