Designing Low-Power, MCU-Based Sensor Modules is Easier than Ever

Download this article in PDF format.

Monitoring and control devices have been around for decades in various forms, but they’re use is expanding in homes as well as in building automation for HVAC, fire safety, and lighting. At the heart of these devices and systems are the sensors that detect the physical characteristic of interest. What makes these devices so advantageous is that microcontrollers can be incorporated to customize and optimize the design to the application. New smaller, lower-cost, lower-power-consumption MCUs are making the design process fast and simple.

Guided by the “less is more” philosophy, companies like Texas Instruments (TI) continue to develop and release new smaller microcontrollers (MCUs) with only a few kilobytes of memory. Such devices with low-power consumption address hundreds of applications that can benefit from them since they can replace standard logic or some analog circuits. Often these MCU-based solutions provide new functionality and flexibility, bringing additional value to a design. Examples include a battery-powered thermostat and an IR smoke detector.

Thermostat Reference Design

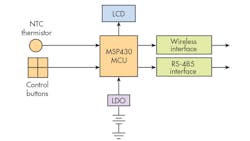

At the heart of a typical modern thermostat design is a low-power MCU with RAM, ROM, or flash along with multiple I/O interfaces (Fig. 1). The temperature sensor is a negative-temperature-coefficient (NTC) thermistor. Its output is converted to digital by an internal analog-to-digital converter (ADC). Other inputs are multiple pushbutton controls.

For output, a liquid crystal display (LCD) is typically employed. Another output is an interface—either wired or wireless—to the remotely controlled relay that switches the HVAC unit off or on. For power, the thermostat uses an internal battery or perhaps a standard 24-V ac supply. The dc is commonly conditioned by an LDO regulator. Most thermostats today are some variation of this configuration.

TI offers a reference design with a similar configuration. Called the TIDM-FRAM-THERMOSTAT, this product gives you a head start in producing a version of your own. It uses TI’s popular MSP430 series of 16-bit RISC MCUs, specifically the MPS430FR4133. This MCU uses ferroelectric random-access memory (FRAM), a kind of non-volatile memory that can replace SRAM or flash memory.

FRAM uses a cell similar to a standard DRAM cell that stores bits in a capacitor. Using a ferroelectric dielectric in the capacitor allows data to be retained when power is removed. FRAM is fast, uses little power, and is reliable. This model MCU offers 15.5 kB of FRAM and 2 kB of standard SRAM.

The temperature sensor is a thermistor that feeds a representative voltage to an internal 10-bit ADC at 200 ksamples/s. It uses a 1.5-V internal reference or 1.2-V external reference. Four capacitive touch buttons are also provided for inputs.

The output uses a 3.4-in. LCD module that supports 4 × 36 or 8 × 32 segments. Interfaces include UART, SPI, and I2C. This reference design also offers an RS-485 interface that’s commonly found in commercial or industrial applications for connecting to the remotely controlled equipment. The RS-485 interface is external to the MCU. Connections for a wireless interface, such as Wi-Fi, are built-in as well.

Power to the reference design board is by way of two AAA batteries conditioned by an LDO regulator. Standby current is 1.8 µA and average current draw is only 10 µA. Matching software is provided.

Photoelectric-Sensing Reference Design

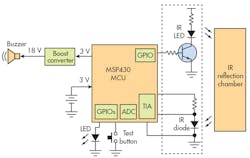

TI also offers a reference design of a photoelectric infrared-reflection-sensing subsystem for applications such as smoke detectors. Called TIDM-FRAM-IRREFLECTIONSENSING, it uses an ultra-low-power MCU to enable more than 10 years of life on a single CR123 battery. The MSP430FR2311 MCU has an integrated transimpedance amplifier (TIA) and can provide EEPROM emulation to shrink board size and cost.

Figure 2 shows the reference-design components. The MSP430FR2311 MCU features 3.75 kB of FRAM and 1 kB of SRAM, a 10-bit ADC with window comparator, two 16-bit timers, and a real-time clock. Interfaces include UART, SPI, and I2C.

An interesting feature of this MCU is the internal TIA. The TIA is a low-noise, high-gain, high-input-impedance, picoamp-level, input-leakage op amp optimized for current inputs. It takes a low input current and amplifies it to a useful level. In this reference design, the input is an infrared photodiode that detects IR light and generates a proportional current that’s usually very small. The IR diode and its gain resistor are external to the MCU.

The IR diode is part of a submodule designed to detect smoke. Also in the module is an IR light-emitting diode (LED) driven by one of the general-purpose I/O lines. Both diodes are positioned in a reflection chamber, but in a way whereby they don’t point to one another directly. The MCU is programmed to read the IR photodiode output with the reflected light from the IR LED both on and off to establish a reference range. When smoke enters the chamber, it scatters the IR light, producing a different reading from the TIA that’s digitized and used to determine the threat level.

When a heavy smoke level is detected, the MCU activates a loud audible buzzer. An external dc-dc boost converter is needed to power the buzzer. Power for the whole reference design comes from a CR123 3-V battery. Average current consumption is 1 µA.

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.