Temperature is the most frequently sensed physical variable, so it’s no surprise that literally tens of thousands of sensors are available for it. At the same time, it’s also not surprising that there’s always a need for other digital-output temperature-sensor device offering new features, functions, or performance, as demonstrated by two very different new families.

Devices in the EMC181x family of remote diode-sensor interface ICs from Microchip Technology monitor one internal diode and up to four externally connected diodes depending on model; it includes what the vendor says is the industry’s smallest five-channel temperature sensor with standard lead spacing. External sensed reading is accurate to ±1°C or ±2°C (maximum error) depending on the sensed range; internal sensor accuracy is to ±°1C; all readings have 0.125°C resolution. The ICs interface via a two-wire, I2C-compatible bus (400-kHz clock rate) with 1.8-V logic levels, compatible with the EIA/JEDEC 8-7 Standard.

These diode-based temperature interfaces go beyond providing basic readings from the associated diode sensors (note that diodes are widely used as inexpensive transducers, but they have technical subtleties that must be recognized and addressed). The EMC181x family members embed user-settable rate-of-change alarms, useful for preemptive action without processor involvement.

Another advanced feature is resistance error correction (REC), which automatically eliminates the temperature error caused by lead series resistance, thus allowing greater flexibility in routing of the thermal diode. Then there’s beta compensation (BC), which eliminates temperature errors caused by low, variable-beta bipolar-junction transistors of today's fine-geometry processors. As a result, the user needn’t provide unique sensor configurations for each temperature-monitoring application.

For design-in support, Microchip’s PC-hosted, USB-based ADM00773 evaluation board comes with Microchip’s Thermal Management Software graphical user interface (GUI). It simplifies evaluation of user-set features such as rate of change, temperature alert limits, and REC, in addition to providing off-board temperature measurements and data logging. Pricing for the EMC1812T two-channel sensor begins at $0.44 USD per 10,000 units.

TI’s New Temp Sensors

Texas Instruments has also introduced temperature-sensor products, focusing on high-accuracy, low-power applications. The company maintains that its TMP117, with ±0.1°C accuracy across a wide temperature range, is the industry’s first single-chip temperature sensor to offer performance comparable to widely used platinum resistance temperature detectors (RTDs), but with many advantages (Fig. 1). Its sibling, the TMP117M, is a digital temperature sensor for medical applications, and meets the requirements for medical thermometers.

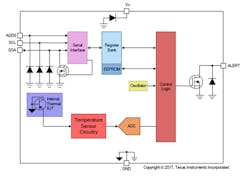

1. The TMP117 and TMP117M digital temperature sensors from Texas Instruments target industrial and medical applications, respectively, and include features such as alerts and averaging.

These digital-output temperature sensors offer both SMBus- and I2C-compatible interfaces, and provide readings with 16-bit resolution to 0.0078°C (1 LSB). Power requirements for these 1.8- to 5.5-V ICs are minimal—just 3.5 μA/6.3 μW during a 1-Hz conversion cycle and 150-nA shutdown current. This low power level greatly reduces self-heating as a source of error.

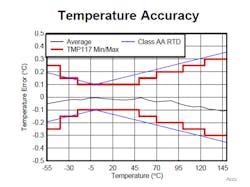

For industrial settings, the TMP117 offers accuracy comparable to industry-defined standards for a Class AA RTD, while requiring far less power than that needed for a PT100 RTD (Fig. 2). It also simplifies the design effort by removing many of the complexities and subtleties of RTDs, such as the need for precision references, matched traces, complicated algorithms, and calibration.

2. Along with high accuracy and resolution, the TMP117 devices offer full traceability to relevant industry standards.

For medical applications, the TMP117M provides ± 0.1°C accuracy from 30 to 45°C and supports American Society for Testing and Materials (ASTM) E1112 and International Organization for Standardization (ISO) 80601 requirements for patient thermometers. Due to the high accuracy across a wide sensing range, most applications can avoid time-consuming, costly final-product calibration.

Other features include programmable temperature alert limits, selectable averaging, digital offset for system correction, and 48 bits of general-purpose EEPROM. The TMP117 units are 100% tested on a production setup that is NIST traceable and verified with equipment that’s calibrated to ISO/IEC 17025 accredited standards.

The TMP117EVM Evaluation Module and its GUI (which runs online or through a desktop installation) provide a quick and simple way to start using the TMP117 to gain familiarity with the device, down to the bit-by-bit register level. The EVM hardware features a perforated “break-out” portion, so the user can physically separate the TMP117 and still interact with and configure the device.

The 49-page datasheet also includes detailed application information related to suggested layout, noise and averaging, self-heating effects, and synchronized readers. The TMP117 digital temperature sensor and TMP117M digital temperature sensor for medical applications are housed in a 2.00 × 2.00 × 0.8 mm WSON and priced at US$1.60 and US$2.44, respectively, in 1,000-unit quantities.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.