Resonant Electro-optical Temperature Sensor is Immune to Interference

There’s apparently little limit to the innovative ways that are available to sense temperature, among the most widely sensed physical parameters. Now, a team Washington University in St. Louis has devised and tested what they claim is the first to do so by adding electronics to a photonic sensor resonator with a whispering-gallery-mode (WGM) architecture. In a WGM arrangement, the sensor resonates at both appropriate wavelengths of light and at vibration or mechanical frequencies. Their sensing design includes a wireless link so that the data can be provided in real time, and the unit can be monitored and controlled even in mobile applications.

Why even develop such a complicated sensor when there are so many available ways to measure and monitor temperature, whether in direct contact and remotely? According to Prof. Lan Yang, who led the project, the primary reason is that these optical sensors are "immune to electromagnetic interference and can provide a significant advantage in harsh environments."

Whispering Gallery Mode

The WGM approach is simultaneously simple and complex. In WGM devices, an optical microresonator confines the light of an impinging laser beam within a small volume using the well-known principle of total internal reflection (which is also used in optical-fiber links, of course). Using a resonator in this way greatly increases the magnitude of changes that occur in the behavior of the light and its spectral properties (such as frequency shift/splitting and linewidth broadening), which are due to various environmental changes. WGM-based sensors are already used for humidity sensors, magnetometers, nanoparticle/biomolecule detection, atomic ion detection, and optical gyroscopes.

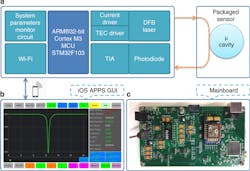

In this design (Fig. 1), a WGM microtoroid resonator is fabricated using a UV-curable low-index polymer to package a microtoroid along with a tapered-fiber optical waveguide. Light from a tunable laser at a nominal wavelength of 976 nm and a linewidth of 10 MHz is sent into this sensor and then received by a photodetector.

1. Shown is the architecture of the wireless WGM sensing system (a); screenshot of the customized iOS app for wireless control of the sensing system (b), and a photograph of the mainboard that integrates all of the electronic components. (Source: Washington University in St. Louis)

The frequency of the laser output can be precisely tuned by adjusting the laser current and temperature, with tuning coefficients of 0.002 nm/mA and 0.07 nm/°C, respectively. At the same time, a 40-mA sawtooth wave is applied to the laser diode, and the frequency of the output is scanned via a photodetector and transimpedance amplifier (TIA) to determine the transmission spectrum of the WGM sensor. Xiangyi Xu, the paper's first author and a graduate student in Yang's lab, noted that “the sensor itself is made of glass and is the size of just one human hair; it is connected to the mainboard by a single optical fiber.”

Electronic Support

Such an arrangement also requires a substantial amount of supporting electronic circuitry in addition to the WGM and basic laser functions. At the system level, an ARM Cortex-M3 microcontroller provides control of laser voltage, current, and temperature (via a thermoelectric cooler, or TEC), as well as acquisition of the transmission spectra of the WGM sensor. A Wi-Fi transceiver provides a link between the sensor node and associated smartphone for transmitting the sensed signals and system status updates, as well as receiving control and management commands.

As with all laser-based systems, stability is a critical factor in achieving viable results, so they developed a customized iOS app to manage the thermoelectric cooler (TEC) and many other functions. A system-monitor function on the main board of the system, which measures 127 × 67 mm (about 5 × 2.5 in.), monitors key parameters such as power-supply and microcontroller voltage rails, and the voltage, current, and temperature of the laser diode.

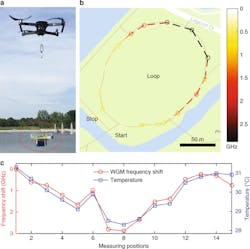

The team tested their design in both fixed and mobile scenarios. For the fixed arrangement, they placed the unit on an exterior wall with the WGM sensor in full contact with the surrounding air, but protected from direct sunlight over a 12-hour period. In the mobile test, they flew a drone carrying the unit in a selected area of a city park to measure the small but definite variations in local temperature distribution. The results were quite close to those from a commercially available high-accuracy thermometer placed adjacent for comparison (Fig. 2).

2. Photograph of a drone carrying the wireless sensing system (marked in the red dashed ellipse) (a); the frequency shift of the selected resonance mode when the drone flew in a loop, with the color bar representing the relative amount of frequency shift (black bar on map = 50 m) (b); comparison of the measured frequency shift with the results from a commercial thermometer (c). (Source: Washington University in St. Louis)

Full technical details are available in their paper “Wireless whispering-gallery-mode sensor for thermal sensing and aerial mapping,” published in Nature’s “Light: Science and Applications.” Whether this approach and associated design (which was supported by an Army Research Office grant) has benefits that outweigh its complexity, or is a solution that addresses a problem which already has other and less-costly solutions, remains to be seen. Nonetheless, it’s yet another tangible demonstration of how lasers, electronics, and photonics are combining produce new approaches to measurement challenges.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.