With the wires inside chips growing smaller and closer together, miniature shower heads installed in their packaging could help keep them cool, spraying coolant directly onto the surface of the integrated circuit. The rinse could prevent chips from burning themselves up as semiconductor companies push performance boundaries.

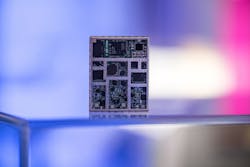

That technology was recently introduced by semiconductor researcher Imec to help meet the growing demands of high performance electronic devices, including three-dimensional chips. These integrated circuits wire together memory, processing and other blocks to get around the limitations of existing chips, which have trouble handling artificial intelligence and other tasks.

“Our new impingement chip cooler is actually a 3D printed ‘showerhead’ that sprays the cooling liquid directly onto the bare chip,” said Imec’s Herman Oprins, senior research engineer focused on thermal management, in a statement. “3D prototyping has improved in resolution, making it available for realizing microfluidic systems such as our chip cooler.”

Imec's system is designed to be integrated into packaging wrapped around these integrated chipsets, which carry with them persistent thermal issues. The Leuven, Belgium-based Imec was able to manufacture the system out of polymer all at once, cutting production cost and time. The researcher would not say when the cooling technology could be generally available.

Imec says that its system evenly distributes coolant over the surface of the integrated circuits. The tiny spouts inside the system, which measure 300μm – or roughly twice the width of a human hair – can be custom manufactured to match specific heat maps, lowering the chances of hot spots forming. The nozzles can also be made to fit inside the chip’s packaging.

The spouts shoot liquid into a small space in between the cooling system and the surface of the semiconductor before heated coolant is expelled through separate plumbing. Traditional chip cooling systems use heat spreaders attached to the bottom of the substrate, but the thermal materials bonding the heatsinks in place have predetermined heat resistances, which is a major limitation, Imec said.

Tiny irrigation channels can also be etched onto the back of the substrate and flooded with coolant that absorbs heat as it flows over hot spots. But that technology can leave some parts of the integrated circuit hotter than others. Cooling systems like Imec’s can also be manufactured with silicon, but it can expensive to customize them based on the chip’s packaging – a shortcoming that Imec said that it can avoid.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.