High-Functionality IC Monitors Health of 12-V Vehicle Batteries

Despite all of the changes in automotive power, the lead-acid nominal 12-V battery is still the key power source in most cars. It works hard and works surprisingly well, but the increasing demands being placed on it call for new and more sophisticated monitoring of its key performance metrics. The ADuCM331WFS IC developed by Analog Devices (Fig. 1) integrates all of the features and functions needed to precisely and intelligently monitor, process, and diagnose the top parameters—current, voltage, and temperature—over a wide range of operating conditions. The IC can, of course, also be used for medical and industrial applications as well as vehicular designs.

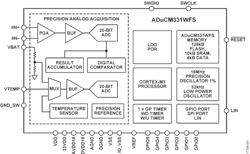

1. Analog Devices’ ADuCM331WFS IC contains front-end and basic-processing functions for detailed monitoring of 12-V lead-acid battery vitals of current, voltage, and temperature. (Source: Analog Devices)

The front end of this data-acquisition system includes dual high-performance, multichannel, 20-bit sigma-delta ADCs sampling between 4 Hz/s and 8 kilosamples/s; the resolution minimizes the need for range switching across their −200- to +300-mV input range. The ADCs, along with a ×4 to ×512 programmable-gain amplifier (PGA) and −200- to +300-mV input range for the current channel, plus a precision reference, capture the data needed to assess the state of the health and charge of the battery.

Supporting these converters and the system functions are a 32-bit Arm Cortex-M3 processor along with 128-kB flash/EE memory and 4-kB data flash memory. To minimize the need for external system components, the component is self-powered directly from a 12-V battery, with on-chip LDO regulators developing the supply voltage.

Additional on-chip peripherals, which can be configured under software control and so tailored to the application, include an SPI interface, serial input/output communication controller, six GPIO pins, and thee timers (general-purpose timer, wake-up, and watchdog). There’s also a LIN network physical interface for single-wire, high-voltage communications in automotive environments (Fig. 2).

2. Interconnection of the ADuCM331WFS with the car system requires only a few sensors and passives, plus protection components and selected I/O interfaces. (Source: Analog Devices)

Since low-power operation is critical in vehicles (especially with respect to any minuscule but cumulative “vampire drain” even when it’s not in use), the ADuCM331WFS requires 18.5 mA when all peripherals are active. However, it can be configured via software to implement various ultra-low-power modes with current dropping to under 100 μA. It’s housed in a 6- × 6-mm, 32-lead LFCSP, fully specified for −40 to +115°C operation with additional specifications for 115 to 125°C, and is automotive qualified. The device costs $4.36 (1000-piece lots).

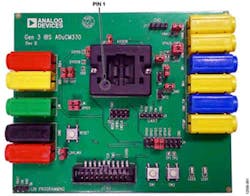

To support product design-in, a companion EVAL-ADUCM330 evaluation board is available for $105.20 (single piece) along with software tools (Fig. 3). This board provides for quick removal and insertion of a device via a 32-lead LFCSP socket, as well as the connections needed to allow for rapid measurement setups.

3. The EVAL-ADUCM330 evaluation board facilitates hardware and software integration and operation of the ADuCM331WFS. (Source: Analog Devices)

Switches and LEDs are supplied on the applications board to assist in debugging and code development. The board is also supported by the Keil MDKARM evaluation version integrated software-development tool and Segger debugger with USB interface driver, utilities, and a dynamically linkable library. In addition, sample code blocks are provided to show key features of each peripheral and examples of how they can be configured.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.