PHY Transceiver IC Takes on 100-Mb/s Automotive Ethernet

Think back a decade or a little more, and the “conventional wisdom” of many presumed experts was that high-speed Ethernet for autos was (pick one or more): unneeded; too difficult to achieve; too costly; and/or required space-consuming coaxial cable. And, therefore, it wasn’t going to happen in the near future. But now fast forward to 2018. We know how that trajectory has actually played out, where providing such high-end connectivity in cars is now a must-do project.

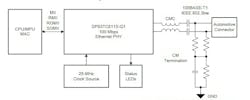

Still, making it happen takes high-performance auto-compatible building blocks, one being the Texas Instruments DP83TC811S-Q1 transceiver IC (see figure), which is compliant with the IEEE 802.3bw-2015 100BASE-T1 standard. It provides the physical-layer functions needed to transmit and receive 100-Mb/s data over a single unshielded, low-cost, lightweight, twisted-pair cable. Its small size (6 × 6 mm) and high degree of integration trims external-component count, cuts PCB footprint, and reduces power requirements to about half that of available solutions, according to the vendor.

Texas Instruments’ DP83TC811S-Q1 transceiver implements the IEEE 802.3bw-2015 100Base-T1 standard, providing physical-layer interfacing for automotive Ethernet connectivity via twisted-pair cable at data rates to 100 Mb/s.

This 100Base-T1 device supports SGMII (serial gigabit media independent interface) and enhances design flexibility by enabling connections to multiple switches and interfaces. It also supports a full range of other media independent interfaces (MIIs), which enables designers to implement Ethernet connectivity with various media access controllers (MACs) and processors. As the auto environment is not a benign setting, the DP83TC811S-Q1 embeds a “diagnostic toolkit” to monitor the system for performance and cable breaks. It does this via signal quality indication (SQI), time-domain reflectometry (TDR), sensing of temperature and voltage variations, PRBS self-test, and even a patent-pending ESD-event sensor. The latter counts such events on both the xMII and MDI to provide real-time monitoring via a programmable Interrupt.

Among the IC’s objectives are enabling simplified layout, flexible design, and high-speed, reliable performance. The SGMII requires just four package pins rather than the 12 required for reduced gigabit media independent interface (RGMII), while the integration of a physical medium-dependent (PMD) filter, MII series terminators, PMD termination, and power-supply filtering components reduce board size and number of needed traces, to ease layout challenges. Further, device latency as low as 140 ns allows latency-critical systems such as automotive advanced driver-assistance systems (ADAS) to respond and communicate more quickly.

An IC with this complexity and sophistication needs tools and support for effective, frustration-minimized design-in. TI offers support via evaluation modules: the DP83TC811SEVM for SGMII and the DP83TC811EVM for RGMII. Additional support documentation and information includes:

- Reference design documentation, “Automotive Stand-Alone Gateway Reference Design with Ethernet and CAN”

- White paper, “100BASE-T1 Ethernet: the evolution of automotive networking”

- Blog, “The importance of automotive Ethernet standards”

- Application report, “DP83TC811 IEEE 802.3bw Compliance and Debug”

To enhance ruggedness, the DP83TC811S-Q1 incorporates 8 kV of ESD protection, with an AEC-Q100 Qualified for Automotive Applications rating. The 3.3-V device features configurable I/O voltages of 3.3 V, 2.5 V, and 1.8 V, and requires under 230 mW in active-mode operation (its sleep, standby and disable modes require far less). The 36-pin, wettable flank, very thin quad flat no-lead package (VQFNP) DP83TC811S-Q1 is priced at $2.25 in 1,000-unit quantities.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.