States are Gunning to Ban 3D Printers and CNCs

What you'll learn:

- Washington, California, and New York have sponsored legislation in play that could turn selling a 3D printer or CNC into a felony with five years of imprisonment.

- The American tradition of basement/garage innovation and manufacturing is methodically being shut down under the guise of public “safety,” trampling a wide swathe of capability and innovation brought by these tools.

Safety is a ruse

That’s used to remove our rights

One gun was printed

Hot on the heels of the ban on foreign-made drones and drone parts, several states, including Washington, California, and New York, have jumped on the Karen wagon and drafted legislation to ban 3D printers and CNC machines from sale. That’s until they can run software recognizing whether or not they’re printing a prohibited item, like the lower receiver of an AR-15 rifle/pistol. A registry of prohibited items would be listed by the state attorney general, updated annually.

Note that this isn’t exclusive to privately owned 3D printers and CNC machines. It also could affect small business and large industrial manufacturers and their suppliers, like Boeing. The exception is made only for those who are licensed as federal firearms manufacturers. Yes, really.

Thoughts Up in the Air

3D printers and I go way back, about a couple of decades. Back then, I decided to leave the spouse and kids in Oregon (better schools, kids had friends there, housing costs, general family stability) while I “commuted” to and from the Bay Area to work at Altera and National Semiconductor.

The whole airport/TSA thing got tiresome with the lines, delayed flights, and the inability to carry on items like a bottle of wine, tools, etc. It meant checking luggage, adding 20 to 30 minutes to my Monday morning flight.

I did the math and wound up buying a private plane, which cost about the same as my monthly airfare in terms of payments. It got me, door to door, in about the same, sometimes less, time, with no bags to check, no security lines, and I got to build time in one of my joys in life — flying.

The Mooney M20K 305 Rocket was an “STC”-approved hot-rodding mod of an already fast aircraft, stuffing a huge turbocharged engine into the airframe. The consequences of doing so meant the tail had to work harder in balancing the plane with its downforce. This led to the issue of a mandatory inspection for stress cracks every 50 (or maybe it was 100) hours.

Around the same time, I became a founding investor in TechShop, a Bay Area startup that franchised maker spaces with milling machines, lathes, welding machines, CNC mills, a waterjet, CNC router, vacuum former, 3D printers, etc. Members could use them after taking a mandatory three-hour class and maintaining a membership along the lines of a gym business model.

The 3D printer we had started off with was a donated Stratasys Dimension series, iirc, so I decided to 3D-print airfoil-section fairings to streamline some of the sloppy tubes that protruded from my Rocket (round tubes/wires have huge drag, even if small in diameter). I also welded up a steel mold at the maker space for a counterweight of poured marine ballast (done by a foundry for me in the East Bay) to go into the tail, to relieve the downforce stress on the tail. And there was the added bonus of reducing induced drag from the tail airfoils.

The mods worked. I even got a call from ATC, during one of my commutes, asking me to confirm that I was indeed a Mooney, as filed, because he was showing a ground speed of 220 knots at 11,000 feet. Tools and a shop — they enable innovation and capability, whether prototyping, in production or innovating incrementally. Innovate fast, innovate often. Failure is not tolerable.

I’ve also had several 3D printers over the years, starting with the Makibox, to the point of collecting weird ones off Kickstarter. Filament printers and resin printers of all kinds and all sizes.

So, a usual part of being an EE is designing and building electronics or systems that require mechanical objects, whether it’s a case, a bracket, a mount, or a mechanism. Some of my designs included other, larger, 3D printers, using laser-cut panels and stretching an Ender-5 Plus to make larger prints (in progress).

I’d thankfully picked up the latest Czech machine before all of this craziness in U.S. relations with the EU began. As I write this, a 25% tantrum tariff will be applied to your Czech printer starting this summer (you have until Feb. 1 for the latest tantrum to kick in), and you pay that extra tariff money to DHL or your shipment doesn’t get to you. [Editor note: Breaking news: After we had written this piece, the European tantrum tariffs got "TACO'd."]

Expanding my capabilities over the years has also encompassed subtractive manufacturing, which included a desktop CNC milling machine that I’ve had for almost three decades (runs on an XP machine’s parallel port; that’s how old it is). However, it’s not exactly well-suited for hogging out blocks of aluminum billet with its ¼-inch threaded rod linear mechanism.

I’d always kept my eyes open for a larger machine and I found a VMC on Craigslist being sold by Peter, who had a day job at Nike. He also had a machine shop in his garage that was making aerospace parts as a subcontractor to a Boeing supplier as a side-gig. The machine was giving him problems with Z-axis overshoot, so he replaced it with a new HAAS.

I got the Fadal for a song, and it’s sitting in my garage, waiting for me to hook power up to it and fix its Z-axis gremlin after Peter had already thrown a new servo and ballscrew at it. Peter resigned from Nike soon thereafter and has been running the shop in his backyard for all these years.

Getting Hammered at College

About three years ago (I wasn’t working a day job at the time). I decided to take full-time classes at Portland Community College to learn how to TIG weld aluminum, and eventually titanium (haven’t gotten to Ti yet). My classmates told me about an art(!) class they were taking: metal foundry.

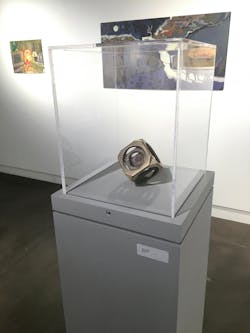

Now, I’d taken blacksmithing classes (at Duke University, no less) and always wanted to learn and do foundry to create almost-net-shape parts vs. hogging out big blocks of aluminum billet. I signed up for the class and had a very tolerant instructor who let me experiment. I was the first student at the school to cast metal directly from a 3D-printed pattern (Fig. 1).

In a subsequent semester of the same art class, I had bought my 9-year-old minion an Ender-3 3D printer, with the goal of teaching her CAD so that she could make stuff with it. One weekend, I was visiting her in Washington state, and we pulled the printer out and printed the patterns I had designed for my next art class project (Fig. 2).

My experiment ran with PLA (black) and casting filament (white). Note the patterns and raw casting are upside down from their pouring orientation. The two bronze “twisted” (hey, it’s an art class and I designed these in CAD) sledgehammer heads both turned out rather well. I gifted one of the two hammers, with ash handle, to my instructor.

In the bottom left pic of Figure 2, the white plastic spray of segments thing you see in the sprued-up and raw cast at the top of the red main square sprue is a throw-away (I literally pulled it out of the trash can) 3D-printed pattern (the "Eye of the Universe" from the video game "Outer Wilds") a classmate used for making a silicone mold in which to make a wax pattern.

We both poured bronze at the same time and her wax casting failed. The junk pattern I threw in out of curiosity (another experiment where I wanted to see if the head pressure of liquid bronze would compress entrapped air enough to fully fill each dead-end segment...it did) wound up being her bronze art piece that she polished, bejewelled, and gave to her brother for Christmas.

Tools with Weapons

All this shows is that these TOOLS can be used to make art and make other tools. Could I cast a bronze Viking sword? Yes, but college (as with most schools) policy is no weapons on campus, so I couldn’t do it out of respect for the rules. Would the sword be art, rediscovering/living a historical process, or a weapon?

Is my cube construed as art, or a weapon? The sledgehammers: Useful no-spark impact tools, art, or skull crushers? Depends if a person throws or swings it and at what or whom, or if it sits on a table/pedestal or in a glass case, doesn’t it? Could it still be used as a weapon? Of course. Can a shovel? Of course. Art is a form of expression, isn’t it? It’s interpreted.

Therein lies the rub in all of this — intent, sanity, respect, socialization, uncontrolled rage, revenge, payback, malicious determination, bullying are all factors that determine whether an axe can provide heat and light or turn someone’s lights off.

But, then again, a river rock can also kill. Or the jawbone of an ass. Or a slingshot, sharpened stick, or bow and arrow. Or a rental truck. Or a letter opener. Let’s all require chopsticks and require state licenses to be posted in residential kitchens to possess a paring knife, because food can be precut at the grocery store and knives can kill.

A metal detector and two National Guard at each school solves the problem of weapons at schools. But the brain trust that runs the banana republic has determined that they’re better used to beat up and poison unarmed protesters.

Is a parts-per-million programming defect in a few sick minds in an entire population worth oppressing innovation, art, technology, tools creation, one that’s supplying an economy with real goods for the entire population and for export? Are sick minds out there, drunk with I2R, with an agenda that has been quietly pulling strings on state legislators, under the guise of public “safety,” to do exactly that, lately, in the USA?

As engineers, we all know that a turnkey CNC “dedicated” for making “ghost” guns is any machine that can run G-code under the hood. Any machine that can run G-code can have a USB stick plugged into it and produce gun parts.

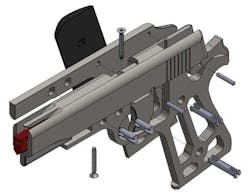

But here’s the thing — the lay/Karen/legislator thinking that any mechanically inept moron can push a button and produce a working firearm in zero time is naive. A gun must be assembled, parts from real guns have to be ordered, all have STEEL barrels that must be procured (and that set off metal detectors), and all of the parts must be hand-fitted, which is within the purvey of skilled gunsmiths. It takes weeks to make one. The printing time is likely days.

John Q. Public with all thumbs and a grudge can’t do it. Luigi Mangione, accused of a serious crime, has a Master’s in Engineering and completed a robotics research internship at Johns Hopkins University might be able to. The video of the actual killer, assuming it’s not AI, shows the gun incorrectly cycling — a lack of skills in assembling the weapon.

This scared Karen stuff is over a capability and a murder-resolve that filters down to three or four dudes in the whole country who can actually make a cycling weapon. One in 110 million: “Do you feel [un]lucky, punk?” The lifetime odds of an American being killed by gun violence is 1 in 315, and legislators in three states are looking at disrupting a wide swath of industries over 1 in 110 million odds?

The 2A marketing schtick of being a “turnkey” gun CNC machine or gun 3D printer, a Star Trek Replicator, is what’s initially being banned in the minds of activists, their lobbyists, and puppet legislators.

However, the slippery slope is that any machine capable of additively or subtractively producing gun components by G-code is next on the list and that nobody is going to upgrade firmware on their 15-year-old workhorse VMC (mine doesn’t have the memory space, LOL, and USB is a kludge retrofit). That’s because there’s nobody willing or capable of writing the firmware required by the crazy boilerplate legislation.

Nobody is going to spend the money on a machine that’s locked down to only making illegal parts when those parts are readily available in a real gun for half to one quarter of the money. Untraceable is the implicit goal, yet somehow it allegedly continues to be carried around for days in a backpack by a valedictorian smart enough to graduate with a Master’s from a top engineering school.

The Pending Legislation

Rather than rewrite what’s already been written on pending legislation, you can read the details here and in the other links I’ve dropped. I’m also appending a video, below, that’s the best at summing up the situation with pending legislation in Washington, a state where we manufacture things like military and commercial aircraft. It affects my minion’s ability to use her printer if the law devolves.

“15-year-old arrested for felony 3D printing after showing her working plastic coin sorter design at Washington regional science fair.”

New York state’s governor also recently announced that she’s going after 3D printers and CNC machines with legislation now in play. California apparently has legislation in play as well, AB 1089. All of this is simultaneous. Deliberate. Coordinated.

Boilerplate legislation is written for governors and legislators with no clue of what 3D printers, CNC machines, or the inventory at Home Depot, currently do for the 99.999th percentile of the sane, law-abiding, people they’re supposed to represent. They don’t seem to realize that the 0.001th percentile know that all they need is a trip to Home Depot to make a firearm (in heavily gun-controlled Japan, former prime minister Abe was assassinated by a home-made shotgun made out of hardware store parts, Fig. 3).

Some understand all of this futility against a determined criminal mind, but say, “let’s do it anyway” as if inalienable rights did not exist:

“Manhattan District Attorney Alvin Bragg conceded that this requirement to stop 3D printers from printing firearms and making the sharing of 3D files for guns and their components illegal will not solve the problem of ghost guns. Nevertheless, he said that these measures would make them more difficult to acquire [by law abiding citizens — there's state law that requires serial numbers to be affixed to home-made weapons already]. “These illegal [they are not illegal if registered] firearms are being manufactured in homes and [a very few are] used in crimes right now, which is why I have been working with my colleagues in Albany and the private sector [who?] over the past several years to stop their proliferation,” Bragg said. “Passing these measures will reduce crime and strengthen public safety for all New Yorkers.” —Tom’s Hardware

“Will not solve the problem of ghost guns.” “Make them more difficult to acquire.” One Udemy course and you’re making them on any 3D printer or on any CNC machine. Do you see where this is going? The one murder we know of has the alleged perpetrator behind bars, so who else is out there? Why isn’t this a weekly thing? Hobbyists experimenting is not a threat to “We The People” according to the real numbers.

New York’s governor is citing the shooting of the UHC CEO as motivation for the legislation, allegedly by a 3D-printed ghost gun. So far, no ghost gun has been admitted into evidence by any court of law, but it’s an excellent premise to pass legislation. Never waste a good tragedy to gnaw away at inalienable rights until there are none.

There’s some kind of obvious economic and innovation destruction in play as a long game here. Unless, of course, we all register as federal arms manufacturers to be able to print Benchies, a model airplane, a science fair project, and a fidget spinner in a few years, just because one or two knuckleheads out of 340 million decide to kill someone with a 3D-printed, or CNC’d, weapon. Their next recourse could just as easily have been, and would have been, a tool out of the garden shed, a machete, rental vehicle counter, or anvil dropped off a cliff. And would be, as demonstrated in the UK, France, and in the Grand Canyon. Meep meep.

AI Knows Everything, Right? Right......?

There’s an out from getting a federal firearm manufacturing license, though: It’s to allow, presumably, AI to determine, in firmware or in the slicer/CAM software, whether a component to be printed is on the Washington secretary of state’s banned thingies list. Or if what’s being printed is determined by AI to be a gun component.

Say you’re prototyping a release mechanism for a quick release for a suspended load. AI will likely say, no, sorry, that’s a trigger mechanism. Power-activated fastening device, like Hilti? Or an airbag for protecting cyclists or old people from breaking a hip? Nope. AI says that's building a gun. What about Figure 4? Or the frame in Figure 5? What’s your judgment human? What do you think an LLM would conclude?

While some may not care about all this and think it’s better to have a bit more safety than none, I for one work on IP research and development. The last thing I want is an AI looking over my shoulder, learning my process and my design, just to pass it on to competitors or, worse, other AI.

Not only is the proposed firmware in a machine crippling, its G-code generator, whether a slicer for 3D printing or CAM for a CNC, now needs the ability to recognize what you’re doing and to call out to the Sec State’s AI to see if there’s a flag on the “blueprint,” whatever that means.

The images above are from an STL (files) repository; then G-code is produced from them. They’re rubber-band guns, by the way. The AI likely won’t let you make them because it still has trouble with drawing human fingers, so... “it’s a firearm.”

Then there’s the slippery slope of incremental improvement — taking an existing item and building IP on its design. Patent law encourages this, but if the copyright owner registers the design in future, you’re not going to be incrementing anything.

Creeping Inelegance by Creeps

If this legislation passes in Washington state, it goes into effect in 2027. It’s got 26 legislators sponsoring it. One year to completely turn the entire manufacturing and innovation base on its head in terms of G-code generation and firmware revisions to 3D printers and CNC machines because Washington’s language encompasses all machines, not just the gun-dedicated ones the way I read it (Figs. 6 and 7).

It’s insane. The supply of machines to Washington will totally dry up, and having an AI lurking is a massive security hole. New York state appears to be cutting and pasting Washington. California is the most watered down of the three, but whoever is behind all of this will likely push for the same. If these three big markets demand firmware and software changes, that means the entire U.S., possibly world, market may be affected.

CA 1089 is here. I’m including a copy of Washington HB 2321 here for readers’ convenience. New York politicians are claiming the lead, but they appear to be copying Washington’s draconian bill with the blocking software concept, which California is not — for now.

Call your state rep and Congress critter to put an end to this back-door manipulation of legislation. Otherwise, it could eventually, by incremental legislation as the cockroaches scurry to G-code-agnostic machines, turn manufacturers, engineering firms, small shops and factories, consultants, students, and hobbyists into “ghost gun CAPABLE manufacturing equipment” felons. Or it totally obsoletes their equipment inventory, driving them to bankruptcy in waiting for the backlog of new, compliant machines.

Guns don’t kill economies. Lobbyists, ignorant/gullible legislators, and malicious actors do by conspiring to stop the sale of existing equipment that’s essential to prototyping and manufacturing innovative goods for revenue. Revenue from making real stuff that pays taxes. Washington is going to be in a world of hurt economically if this bill passes. For decades.

Criminals don’t follow laws. The determined ones will write their own code to run homebrew machines, much like the colonists created cottage industry armories during the American Revolution when the British banned guns a year or two prior.

Comments and civilized, non-political discussion welcome.

Note: This is a blog and represents the author’s views and perspectives, not necessarily those of Electronic Design or EndeavorB2B. Its primary purpose was to raise awareness of the potential disruption of essential tools use by industry and innovators. Author is not a lawyer and is not giving legal advice. Readers are encouraged to gather the facts and consult with legal experts regarding potential impact of such legislation in their jurisdiction.

Andy's Nonlinearities blog arrives the first and third Monday Tuesday of every month. To make sure you don't miss the latest edition, new articles, or breaking news coverage, please subscribe to our Electronic Design Today newsletter. Please also subscribe to Andy’s Automotive Electronics bi-weekly newsletter.

About the Author

Andy Turudic

Technology Editor, Electronic Design

Andy Turudic is a Technology Editor for Electronic Design Magazine, primarily covering Analog and Mixed-Signal circuits and devices and also is Editor of ED's bi-weekly Automotive Electronics newsletter.

He holds a Bachelor's in EE from the University of Windsor (Ontario Canada) and has been involved in electronics, semiconductors, and gearhead stuff, for a bit over a half century. Andy also enjoys teaching his engineerlings at Portland Community College as a part-time professor in their EET program.

"AndyT" brings his multidisciplinary engineering experience from companies that include National Semiconductor (now Texas Instruments), Altera (Intel), Agere, Zarlink, TriQuint,(now Qorvo), SW Bell (managing a research team at Bellcore, Bell Labs and Rockwell Science Center), Bell-Northern Research, and Northern Telecom.

After hours, when he's not working on the latest invention to add to his portfolio of 16 issued US patents, or on his DARPA Challenge drone entry, he's lending advice and experience to the electric vehicle conversion community from his mountain lair in the Pacific Northwet[sic].

AndyT's engineering blog, "Nonlinearities," publishes the 1st and 3rd Tuesday of each month. Andy's OpEd may appear at other times, with fair warning given by the Vu meter pic.