Heathkit: An Employee’s Look Back

>> Electronic Design Resources

.. >> Library: Article Series

.. .. >> Topic: Looking Back at Electronic History

For those of you who do not know or remember, Heath Company was the largest kit company in the world. Heath designed and put practically every type of electronic product into kit form. Its products, called Heathkits, were exceptionally popular and many are still in use today.

Over the years, Electronic Design has published many Heathkit-related articles and blogs. Recently, I had a chance to talk with Chas Gilmore, who was a Heath executive. For those of you who fondly remember Heathkit and miss its products, here’s a look back at this amazing company and the lessons it offers.

Chas, what was your affiliation with Heath?

A recent physics graduate, I joined Heath in 1966 as an engineer in the Scientific Instruments department. This was a new group designing laboratory instruments supporting the Malmstadt/Enke, Electronics for Scientists program. The kit business was making great strides.

The audio department was about to introduce the AR-15 FM receiver/amplifier. It had rave reviews, putting Heath in the top tier of the Audio/HiFi market. At the same time, the Ham (amateur radio) department was updating the phenomenally successful SB-line of an HF SSB receiver, transmitter, and transceiver, and modernizing the popular $99 single-band SSB transceiver line (Fig. 1).

My career at Heath had two parts. From 1966-1977, I progressed to Engineering Manager, Product Line Manager (Kit and Assembled) for Instrumentation, and Director of Engineering before joining another division of Schlumberger (then-parent company of Heath), and then starting a software company. I returned in 1984 as VP of Engineering and Marketing, eventually becoming General Manager. By then, Heath was owned by Zenith. I left Heath in 1993 after we closed the kit business.

Is it Heath or Heathkit?

Good question. The legal name was Heath Company. Heathkit was the primary registered trade name. The two names are often used interchangeably—even by those of us who worked there.

Did Heath also offer some products in non-kit form?

Yes, from time-to-time certain kits were offered “Wired” or “Assembled” (we used both terms). Prior to the demise of the kit business in the early ’90s, kit products were always the dominant business.

Why did Heath’s kit business fade away?

The original Heath Company kit business phased out in 1992. The reasons for Heathkit’s demise are more extensive and complex than reasons speculated by folks from the outside, who typically focus on two reasons: Heath could not incorporate modern parts like surface-mount devices, and reduced assembly costs for electronic goods eliminated savings from building a kit. Although these were factors, they are far from being the only reasons.

- Heath accommodated many changes: from point-to-point wiring to printed circuit boards (PCBs); vacuum tubes to transistors; transistors to ICs; and the ever-increasing complexity of electronic circuits. There were plans afoot to make use of surface-mount technology, which would have addressed the first factor.

- Decreasing manufacturing costs took a substantial chunk of “savings” out of building a kit, especially when equivalent assembled products became high volume. One workaround was to focus on products where eliminating the manufacturing labor for an assembled unit remained significant. For example, linear amplifiers for ham radio. Pretty hard to build those with automated production.

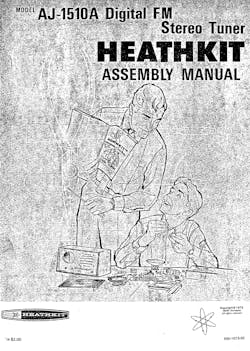

- Heath had significant assembly manual development expense, and the manuals were a great part of Heath’s success. This was a product cost that manufacturers of assembled products didn’t have (Fig. 2).

A lot of the reason for building a kit version of a product was beyond saving labor. The educational value in kit building, satisfaction of building something on your own, the ability to service/maintain the product, and, of course, the satisfaction of successfully building the unit and placing it into operation were all positive forces.

In addition to technology and cost, there were also multiple more subtle factors:

- In the late ’70s and the ’80s, demands on discretionary time increased substantially, limiting the time “Dad” (it was almost 100% a male hobby) could spend on a non-family-oriented hobby. Many popular “big” kits (TVs, HiFi receiver/amplifiers, ham transceivers, etc.) required substantial assembly time—many well over 100 hours. The use of assembled and tested subassemblies reduced build time and increased success on complex products, but eventually even that was too much to meet the demand for instant gratification.

- The rapid growth of personal computers siphoned away many of the “early innovators” (who were a large part of the Heath customer base). These customers were attracted to computer software and enjoyed exploring the infinite possibilities presented by computer programs.

- Electronic products became pervasive—everybody had multiple electronic products, where before a household might have a single radio. As consumer electronic products became extremely popular—HiFi, TV, CB Radio, etc.—increased volumes resulted in lowered costs and removed the “wow factor” associated with having such a product and being able to say “I built that myself.”

- As Heath evolved, it became a subsidiary of large corporations and corporate overheads and expectations grew. As a result, Heath became less nimble (it’s tough to make rapid changes as a part of a large corporation) and found it difficult to achieve corporate expectations of profitability in a market where high-volume consumer electronics set expectations. Management and financial constraints imposed as a division of a large public corporation; Zenith Electronics added additional financial pressure.

In 1993, kits were phased out, leaving Reflex lighting and Heathkit Educational Systems (Fig. 3). These businesses were sold to investors in the following years. In 2012, Heathkit Educational Systems filed for bankruptcy and the assets, including the kit-related assets, were purchased, including the name, trademarks, and copyrights.

Under the new ownership. Heath is still a concern. Not the Heath of old, but an entirely new business. The Reflex Heath/Zenith product line had multiple owners, and now as a part of Ferguson, is sold through big-box stores.

Why were Heathkits so successful for so long?

Certainly, popularity of electronic products and fascination with electronics were huge forces. A big driver in the 1950s was the large number of WWII veterans who, during the war, received electronic training. When reentering civilian life, they wanted to continue to work with electronics.

Commercial equipment was very expensive; Heathkits eased the expense burden substantially. Many early kits followed the 80% rule. That is, they provided 80% of the functionality and specifications at 20% of the price.

User experience was also a driver. As the market expanded from the trained GIs, the manuals became more comprehensive, moving to step-by-step assembly instructions with many detailed illustrations. This enabled interested customers with less electronic experience to successfully build kits. Quickly, Heath adopted the “We will not let you fail” slogan and supported it with a robust Customer Service department, who helped many, many customers achieve the ultimate rush of finding a problem and successfully placing their product in operation.

Was Heath strictly a mail-order business?

Yes and no. From the inception of the electronic kit business in 1947 until the early 1960s, Heath’s sole outlet was through mail order—catalogs/flyers, trade shows, and magazine advertisements. In 1961, Heath experimented with retail stores. These became popular and by the mid-1970s, there were over 60 Heathkit retail stores.

Do DIY hobbyists still want kits?

Yes, electronic kits are quite popular today. The kits are very different from the Heathkits of the past. Many are simply circuits on a PCB, leaving final packaging to the customer. Typically, kits from any one company focus on a single product area. Many are quite inexpensive and few offer Heathkit-level manuals.

Why do you think the original Heath is so well remembered?

Multiple reasons. For a long time (1950s through the mid-1970s), they were the only game in town. Heathkits resulted in a working packaged product. The assembly manuals were the best by far, leading to a very high success rate and providing a great deal of practical electronic theoretical education and assembly skills. Again, the emotional high from completing the kit was great. Many, many Heathkit customers were repeat customers.

Did Heathkit have any real competition? Who?

In the 1950s and 1960s, there were multiple competitors. Two had similarly broad product lines: Knight-Kit (Allied Radio) and EICO. Both had product lines including test instruments, HiFi, ham, and miscellaneous electronic products. Radio Shack appealed to hobbyists, but Heath didn’t see them as a major competitor. They weren’t a kit company and sold a wide range of fully assembled imported products. Probably the main competition was from their very popular TRS80 personal computer, which went up against Heath’s kit computers.

What were the main product lines at Heath, and which was the largest?

Over the long haul, ham and test Instruments vied for the largest. There were times when audio contended for the largest and TV did as well, especially when there were large bulk sales to the home-schooling institutions such as Bell and Howell. It used Heathkits to provide hands-on instruction, with the building of a kit TV being the course cap-stone project.

In the mid-1970s, Heath introduced its own line of instructional products. These became a significant product line for Heath under the trade name Heathkit Educational Systems and were the last remaining Heath product line in the mid-1990s. They had significant sales into secondary and post-secondary education.

When kit personal computers were introduced in August 1977, they soon became by far the largest product line.

Is it true that Heath’s original products were test instruments?

Yes, the “first” Heathkit was the O-1 Oscilloscope. This product was originally introduced in the July 1947 issue of Radio News magazine at $39.50—complete.

What was the best-selling test instrument?

No question—the VTVM. The product started as the V-1. It underwent minor modifications over the years; however, the basic circuit remained essentially the same for its entire life. The last VTVM was sold in 1989.

In 1955, Heath tried a great experiment with the V-7—the introduction of the PCB. There were many at Heath who questioned this move, concerned a PCB would “ruin” the kit building experience. Clearly this wasn’t the case, as VTVM volumes were neck-and-neck with the Cantenna for Lifetime Volume leader and PCBs were part of nearly every kit thereafter.

What was the best-selling ham radio product?

My guess would be the SB-200 Linear Amplifier for Lifetime Dollars (Fig. 4). It was introduced in 1968 (the model number changed to SB-201, making 10-meter band coverage available only with proof of a ham license) and discontinued in 1983. The Heathkit HN-31 “Cantenna,” a 50-Ω dummy load, was introduced in 1961 and remained in the product line until 1991. Likely this accessory outsold any other ham-radio product in sheer numbers, and was my daughter’s first solo build.

Describe the Heath Product Development organization.

Engineering consisted of two major groups: Design Engineering and the Manual department, each about 80 people out of some 700 in total at Heath. Engineering consisted of Ham, Instruments (kit), General, Scientific Instruments, Audio, and TV departments supported by Component Engineering and Drafting. The Manual Department consisted of Writers, Editors, Illustrators and a support group.

I quickly learned a typical kit design took approximately an equal number of Design Engineering and Manual Department hours—no wonder those manuals were so good. Engineering was a major driver of product innovation. Many product ideas originated from Heath engineers.

A marketing/product-planning group with multiple PLMs (product line managers), often coming from engineering, shepherded each product from concept to end-of-life.

Additionally, the Service and Technical Correspondent Departments were staffed with people with strong technical backgrounds. Everyone involved was a user of Heath products and worked together to bring products to market.

It sounds like Heath may have had a unique product-development process to ensure successful kits. What was it?

Indeed, the process was quite unique—as is the kit business. Once the product was defined and approved, work started in Design Engineering. Development was assigned to an engineer who was often part of a two-person team consisting of the engineer and a technician. Occasionally, with larger products like a TV or one of the newer ham transceivers, multiple engineers made up the team.

Engineering development proceeded as do most electronic products with the exception that, from the start, a top-of-mind topic was assembly by a customer at home with minimal laboratory equipment, or even none at all for a non-technical product such as a TV or audio receiver. When a final prototype was in hand and passed the functionality and specification requirements, the engineer turned a prototype and five sets of parts along with a draft circuit description and other assembly information over to the assigned manual writer.

As I noted earlier, writing the manual often took as many hours as the electronic/mechanical design. In the process, the manual writer consumed one or two sets of parts building the product to write and check out the assembly process. Additionally, illustrators prepared the detailed and often expanded-view drawings to accompany the assembly step-by-step instructions.

Early on, Heath discovered drawings conveyed much more information than photographs and the drawing could delete clutter that might appear in a photograph. The manual writer also wrote detailed circuit descriptions and troubleshooting guides.

When the manual draft was complete, a phase known as pre-proof began. Three sets of parts were packed as in production. Employees from the manual department, engineering, and product management built the product according to the draft manual. Engineering tested the completed products and the manual writer compiled all manual markups. Suggested changes and comments were reviewed, and a revised final manual was created.

Was that the main manual test?

No. The next phase was proofbuild. Proofbuilds involved acquiring 25 sets of parts packed according to the final packing instructions. When ready for the proofbuild, 20+ employees were selected from a pool of interested people to build the kits. Like the pre-proof, there was a proofbuild manual review.

Depending on the extent of the proofbuild comments and manual revision (and any engineering revisions revealed by building 20+ proofbuilds), one of two phases occurred. If the proofbuild went relatively well, the product moved to production and was scheduled for a catalog release. If not, a post-proof was scheduled

You mention the engineer always kept buildability in mind. Did this result in unique aspects of the kits?

Yes it did. This became especially true as the kit customers expanded from very technical customers to the more general customer. By the early ’60s, the product volume and breadth of the customer base added multiple unique features to the kits—most derived from customer experience. Two key additions were supplying solder to ensure the use of rosin core solder vs. damaging acid core solder (90% of build problems were associated with soldering) and adding the “Nut Starter” to most kits.

With the introduction of more complex consumer-oriented kits such as color TVs, when a meter was needed to align the product and the customer was unlikely to own a meter, Heath supplied, in kit form, a very simple VOM. With other kits, such as FM receivers, the tuning meter was converted into a meter for alignment purposes.

The advertisement for the very first Heathkit, the O-1 Oscilloscope, used the term “Complete.” That set the tone for the next 45 years. Heathkits didn’t presume the customer would supply any critical items. If they needed it, it was in the kit.

Can you explain how the Heath personal-computer business was conceived?

The personal-computer line is an excellent example of how product concepts came about at Heath. In this case, I had been working with mini-computers as part of our Scientific Instruments products, and had become quite interested in the hobbyist/kit potential for a personal computer. Lou Frenzel was managing the Heathkit Educational Systems business and had been a personal-computer hobbyist/enthusiast for some time. We were good friends and discussed this potential frequently.

Additionally, Heathkit Educational Systems was in the process of introducing a course and accompanying trainer based on the Motorola 6800, and in Engineering we were looking at the Intel 4004 for possible inclusion in a Heathkit. All of these factors came together at the right time.

What was the deciding factor?

The trigger was the Popular Electronics January 1975 issue. Lou and I sketched out some concepts for a Heathkit computer kit. Shortly thereafter, Lou presented the concept at the weekly PDC (Product Development Committee) meeting, chaired by the head of the Product Management group and attended by the president, along with the heads and managers of all major Heath organizations. They were the folks to be sold.

It was a very long and drawn-out meeting, with many, many skeptics. “What would someone do with a kit computer—balance their checkbook?” Finally, after a lot of selling, we left the meeting with development authorization for the H-8—Heath’s first personal computer. We also received the admonition “And don’t come back for any other computer products until this one is on the market and selling at or above forecast.”

We introduced the H-8 (Fig. 5) along with the H-9 ASCII CRT Terminal, the H-10, Paper Tape Reader-Punch, the H-11 16-bit computer (based on the DEC LSI-11), and a substantial collection of accessories. In the course of development, the personal-computer market was growing rapidly, so getting approval to develop additions to the H-8 was nowhere as hard as the H-8 pitch.

First appearing in the August/Fall 1977 Heathkit catalog, computers were given 10 of the 104 pages—a major display for an entirely new product line. For comparison, ham had 11 pages, audio had 15, and test had 21. The “President’s Letter” (see below) showed management was still nervous—would personal computers really sell? And yet, personal computers became Heath’s largest selling product line by year’s end.

What happened to the Heath computer business?

In one word: success. In a few short years, personal computers evolved from the domain of the “techie” or early innovator, to the early adopter, and then to general use. As with many products, once a particular product was no longer confined to the early innovator market, product volumes became large enough to drive costs of assembled product down.

Also, interest in assembling the product from a kit became the domain of a very few. Relative to many other products, the personal computer went through this evolution very quickly. The immediate and intense interest in personal computers quickly drew interest away from kit building as the users were fascinated with what could be done with the computer itself. Early in the life of Heath computers, fully assembled as well as kit computers were offered under the name Heath Data Systems. Shortly, Heath was acquired by Zenith, who changed the name to Zenith Data Systems.

You mentioned one time that Heath was responsible for a number of “Firsts.” What were they?

There are too many to list here, but the back page of the Heath 1966 general catalog lists some 42 Heath “firsts” as of that time (see below). Many of these were the product of Heath employees thinking about how to make construction of a Heathkit successful.

Other “firsts” included:

- A TV with on screen digital Channel and Time display: Elementary Electronics, May-June, 1974 –“The fact is, today’s Heathkit GR-2000 is the color TV the rest of the industry will be making tomorrow…there is no other TV available at any price which incorporates what Heath has built into their latest color TV.”

- A kit microwave oven.

- A kit single-board, 100-W SSB transceiver, priced at $100

- The first frequency counter using 74LS TTL.

- Over 60 retail stores devoted to displaying and selling kit electronic products.

- Mid-’70s catalogs featuring over 400 products in kit form.

Why is it you can still buy some original Heath products online, at hamfests, etc.?

There are two reasons: Volume—over the course of 40+ years Heath produced literally tens of millions of products; and downsizing—many of the people who built those kits are now in or reaching the stage of life where they’re paring back.

Can you summarize how all of this information offers lessons on how to make a successful electronic business?

Probably the single greatest lesson is focus on customer service. Heath lived by “We will not let you fail.” Even before this slogan was formally introduced, it was the company mantra.

Certainly, a secondary driver of success was the employee interest in the products. We all used them at home, vied for the opportunity to build a kit whenever possible, and, as noted earlier, many, many Heathkit product concepts came from the employee base vs. a formal product planning process. Unique products added to that success.

Where can I find more information on Heathkit?

The web is an excellent place to start. Just searching on Heathkit will keep you going for a long time!

Chuck Penson (Ham Call WA7ZZE) has written three excellent books describing virtually all of the products in three major product lines: amateur radio, test equipment, and audio.

Terry Perdue (K8TP), an 18-year veteran of the Heath Ham Engineering Department, produced a very interesting collection of Heath pictures, articles, and documents, including an audio file of an interview with Heath’s first Director of Engineering—employee #19.

Erich E. Brueschke, KC9ACE and Michael Mack wrote an informative article for the Antique Wireless Association titled “The History of the Heath Companies and Heathkits: 1909 to 2019.” It first appeared in the AWA Review.

Lou Frenzel chimes in.

Thanks, Chas. Great overview. My recollection is virtually the same as yours. Heath was a fun place to work for hobbyists like hams and audiophiles, and as you’re fond of saying, “It was like working in a candy factory.”

We both became hams in our high school days, you K1KJY (now W8IAI) and me W5TOM (now W5LEF) and both had early Heath product build experiences. Working at Heath was also a major educational experience because the company had good execs and great business procedures. We learned that a continuous steam of exciting and unique new products, superior documentation, and world-class customer service can make most companies successful. Thanks again for sharing your experience with Electronic Design readers.

Chas responds.

Lou, I have really enjoyed this discussion. It has been an opportunity to review one of the most enjoyable parts of my career. It occurs to me many former Heath technical people are regular ED readers. I am sure some of them can elaborate on Heath’s history and some may have corrections to comments from my 30-plus-year-old memories. I’d love to hear them and other memories.

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.