Varistors: Ideal Solution to Surge Protection

To see this article in PDF format, please click here.

New regulations concerning surge protection are forcing engineers to look for solutions that allow such protection to be incorporated at minimal cost penalty, particularly in cost-sensitive consumer products. In the automotive sector, surge protection is also a growing necessity—thanks to the rapid growth of electronic content in even the most basic production cars combined with the acknowledged problems of relatively unstable supply voltage and interference from the vehicle’s ignition system.

Another growing market for surge protection is in the telecom sector, where continuously increasing intelligence in exchanges and throughout the networks leads to greater use of sensitive semiconductors, and the stringent demands on uptime and availability mean that high susceptibility to disturbances in supply is intolerable.

Surge Protection Solutions

Surge protection devices protect against surges generated by electromagnetic effects, such as lightning or electrostatic discharge caused by a variety of effects. As such, surge protection may be applied at the mains input to combat disturbances on the mains supply external to the operating equipment or internally generated overvoltages usually caused by high inductive load switching.

A surge protector may either attenuate a transient by filtering or divert the transient to prevent damage to the load. Those that divert the transient fall into two broad categories: crowbar devices that switch into a very low impedance mode to short circuit the transient until the current is brought to a low level; and clamping devices that limit the voltage to a defined level. The crowbar group includes devices triggered by the breakdown of a gas or insulating layer, such as air gap protectors, carbon block detectors, gas discharge tubes (GDTs), or break over diodes (BODs), or by the turn-on of a thyristor; these include overvoltage triggered SCRs and surgectors.

One advantage of the crowbar-type device is that its very low impedance allows a high current to pass without dissipating a considerable amount of energy within the protector. On the other hand, there’s a finite volt-time response as the device switches or transitions to its breakdown mode, during which the load may be exposed to damaging overvoltage. Another limitation is power-follow, where a power current from the voltage source follows the surge discharge. This current may not be cleared in an ac circuit—and clearing is even more uncertain in dc applications.

Zener—or avalanche diodes—and voltage-dependent resistors (varistors) display a variable impedance, depending on the current flowing through the device or the voltage across its terminals. They use this property to clamp the overvoltage to a level dependent on the design and construction of the device. The impedance characteristic, although nonlinear, is continuous and displays no time delay such as that associated with the spark-over of a gap or the triggering of a thyristor. The clamping device itself is transparent to the supply and to the load at a steady state voltage below the clamping level.

Low-cost, High Performance Varistors

The main function of the clamp is to absorb the overvoltage surge by lowering its impedance to such a level that the voltage drop on an always-present series impedance is significant enough to limit the overvoltage on “critical parts” to an acceptable level. Modern Zener diodes are very effective and come closest to the ideal constant voltage clamp. However, the avalanche voltage is maintained across a thin junction area, leading to substantial heat generation. Therefore, the energy dissipation capability of a Zener diode is quite limited.

A varistor, by contrast, displays a nonlinear, variable impedance. The varistor designer can control the degree of nonlinearity over a wide range by exploiting new materials and construction techniques that extend the range of applications for varistors. For example, varistors now offer a cost-effective solution for low-voltage logic requiring a low protection level and low standby current, as well as for ac power line and high capacity, utility-type applications.

Compared with transient suppressor diodes, varistors can absorb much higher transient energies and can suppress positive and negative transients. Furthermore, against crowbar-type devices, varistor response time is typically less than a nanosecond, and devices can be built to withstand surges of up to a 70,000A surge. They have a long lifetime compared with diodes, and the varistor failure mode is a short circuit. This prevents damage to the load that may result if failure of the protection circuit is undetected. Varistors typically offer cost savings over crowbar-type devices.

Varistor Operation

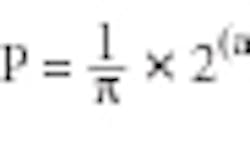

Metal Oxide Varistors, or MOVs, are typically constructed from sintered zinc oxide plus a suitable additive. Each intergranular boundary displays a rectifying action and presents a specific voltage barrier. When these conduct, they form a low ohmic path to absorb surge energy. During manufacture, the zinc oxide granules are pressed before being fired for a controlled period and temperature until the desired electrical characteristics are achieved. A varistor’s behavior is defined by the relation:

I = KVα

where K and α are device constants.

K is dependent on the device geometry. On the other hand, a defines the degree of nonlinearity in the resistance characteristic and can be controlled by selection of materials and the application of manufacturing processes. A high α implies a better clamp; zinc oxide technology has enabled varistors with a in the range 15 to 30—significantly higher than earlier generation devices such as silicon carbide varistors. The V-I behavior of a varistor is shown in Fig. 1 highlighting the distinct operating zones of the varistor. The slope of the protect region is determined by the device parameter β, which bears an inverse relation to a. In fact, varistor behavior can also be described by the relation:

V = CIβ (the inverse of I = KVα)

where C is also a geometry-dependent device constant.

Fig. 1 also compares the varistor characteristic with that of the ideal voltage clamping device, which would display a slope of zero, as well as a Zener diode characteristic. The Zener diode comparison highlights the extended protect region the varistor also offers for a comparable current and power capability.

Selection Criteria

For most applications, you can determine the selection by assessing four aspects of the desired application:

1. The normal operating conditions of the apparatus or system, and whether ac or dc voltage is applied. Fig. 2 shows a flowchart that may be used to determine the necessary steady-state voltage rating or working voltage.

You can find VDRs in various sizes and voltages ranging from 8V up to 1000Vrms or more. The higher the nominal voltage of the selected varistor compared with the normal circuit operating voltage, the better its reliability is over time, as the device is able to withstand more surge currents without degrading performance. The disadvantage is a reduction in the level of protection offered by an over-specified varistor. Hence, you should maintain the following relation:

Maximum withstand voltage of protected device > max. varistor clamping voltage > max. continuous operating voltage.

2. Determine the repetitive peak current. Fig. 3 shows a flowchart that may be used to determine the repetitive peak current. Maximum surge currents are related to the size of the component and start from a few hundred amperes up to several tens of kiloamperes (at standard waveforms of 8/20 µs). Once the repetitive peak current is known, then you can calculate the necessary energy absorption, in Joules (Watt.second or Ws), for the varistor.

3. Calculate the energy absorption. There are two cases—one for dc and one for ac energy. Energy ratings for available varistors start at a few Joules up to several hundred Joules.

Case 1—Calculating dc Dissipation: The power dissipated in a varistor is equal to the product of the voltage and current, and may be written:

W = I × V = C × I β +1

When the coefficient α = 30 (β = 0.033), the power dissipated by the varistor is proportional to the 31st power of the voltage. A voltage increase of only 2.26% will, in this case, double the dissipated power. Consequently, it’s important that the applied voltage doesn’t rise above a certain maximum value, or the permissible rating will be exceeded. Moreover, since varistors have a negative temperature coefficient, at a higher dissipation (and accordingly at a higher temperature) the resistance value will decrease and the dissipated power will increase further.

Case 2—Calculating ac Dissipation: When a sinusoidal alternating voltage is applied to a varistor, the dissipation is calculated by integrating the VI product. A suitable expression is as follows:

Transient energy ratings are quoted in Joules. It’s important to ensure the varistor is able to absorb this energy throughout the planned product lifetime or replacement interval without failing. When the device is being used to protect against transients resulting from an inductive or capacitive discharge, such as switching a motor, the transient energy is easily calculated. However, if the varistor is expected to protect against transients originating from external sources, the magnitude of the transient is typically unknown and an approximation technique must be applied. This involves calculating the energy absorbed after finding the transient current and voltage applied to the varistor. The following equation may be applied:

E = Integral of (everything up to the Vc (t) I (t) Δt) from 0 to Γ = KVcIΓ

Where I is the peak current, Vc is the resulting clamp voltage, t is the impulse duration, and K is an energy form factor constant dependent on the current waveform.

4. Package size and style. Electrical and mechanical considerations must be taken into account when selecting the package size and style. This includes determining the required energy rating and surge current amplitudes, and whether the device is intended to protect against exceptional surges or those caused by repetitive events will feed into the selection process. The amount of energy expected to be dissipated will also influence this, and designers must ensure the package dimensions are appropriate to the physical and mechanical design of the product. Conventional form factors typically range from disc types of a few millimeters in diameter up to 50 mm, or block and rectangular types for high-energy handling parts.

Other important selection considerations are the effects of lead inductance and device capacitance, which also impact the performance of the varistor in circuit, and must be considered when choosing to use a varistor. In conventional leaded devices, the inductance of the lead can slow the fast action of the varistor to the extent that protection is negated.

Modeling the varistor presents a shunt capacitance that may range from a few tens of pF up to several nF, depending on size and voltage range of the device. Depending on the application, the presence of this capacitance can be of little consequence, a desirable property, or, at worst, problematical. For example, in dc applications a large capacitance is desirable and can provide a degree of filtering and transient suppression. On the other hand, it may preclude the use of a varistor to protect high-frequency circuits.

Sample Applications

Looking at Fig. 4, you can see how a varistor may be used to protect a generic load against power surges originating from the supply. The power supply’s own output impedance combines with that of the varistor to create a potential divider whose ratio varies with the varistor impedance to protect the load. You can see an alternative application in Fig. 5. Without varistor protection, the measured peak current through the pump motor when S is closed is 1A. The energy expended in establishing the electromagnetic field in the inductance of the motor is therefore:Without varistor protection, an initial current of 1A will flow through the thyristor bridge when S is opened, and a voltage sufficient to damage or destroy the thyristors will be developed. Arcing will occur across the opening contacts of the switch. But with a varistor inserted in the circuit, the peak voltage developed across the varistor on opening switch S is:

V = CMAX × Iβ = 600V.

The thyristors in the bridge can withstand this voltage without damage. The total energy returned to the circuit is 200 mJ. Of this 200 mJ, 15.1 mJ is dissipated in the heater, and 184.3 mJ is dissipated in the varistor. The varistor can withstand more than 105 transients containing this amount of energy. For further reference, Fig. 6 shows how varistors may be used to suppress internally generated spikes in a TV application.

New Paths of Development

Varistors offer cost savings and performance advantages over crowbar-type surge protectors and Zener diode clamp devices in a wide range of applications. Enhanced materials and optimized component design—particularly in the field of Zinc Oxide varistors—have opened up new applications for varistors, especially those requiring low protective level and a low standby current.

In line with this industry’s overriding drive toward miniaturization and surface-mount technology, VDRs in a single-layer SMD package are emerging to satisfy medium energy handling capabilities within a relatively small volume. Also, where disc-type varistors occupy relatively large space within an enclosure, new low-profile varistors reduce the maximum height above the board for such a device, while maintaining equivalent current handling capabilities. In addition to these, ultrahigh surge varistors are also more widely used in the market, capable of offering an improved surge current/size ratio and allowing replacement of large components by smaller devices with similar performance and reliability.

Other new varistor types incorporate a thermo fuse to provide a predictable “fail-safe” behavior in case of abnormal use. Further avenues of development include varistors capable of handling ambient temperatures above 125°C over the full voltage/surge capability range. PETech