Solve the Build vs. Buy Dilemma with Compact COTS Modules

Download this article in PDF format.

In an effort to reduce costs and accelerate development cycles, the U.S. Department of Defense coined the term commercial-off-the-shelf, or COTS, for packaged technology available in the private sector. Now, in industries ranging from medical diagnostics and transportation to precision agriculture and entertainment, engineers are increasingly challenged to find new ways to design in greater intelligence, connectivity, and performance—while cutting costs, power consumption, and size. Even for companies with deep engineering expertise, many are choosing COTS solutions and reallocating those resources where they can have a greater impact.

It can be a daunting task for OEMs to determine which system elements should be designed versus those that should be purchased off-the-shelf. Although design needs will vary based on important application criteria, industry, and deployment environment, certain characteristics are consistently found across implementations. As engineers continue to refine their designs and rank their functional priorities, the following criteria can serve as a useful springboard for the consideration and evaluation of development tools that range in complexity and capabilities, including system-on-module (SoM) and single-board-computer (SBC) options.

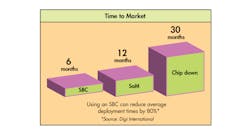

1. Comparing the time to market between single-board computers and systems on modules.

Systems on modules and single-board computers are ideal platforms for quick and focused product design (Fig. 1). They continue to evolve in sophistication, and the range of possibilities continues to expand as well. And as those capabilities grow, so do the choices for design engineers. But what are the factors that matter most in SoM and SBC evaluation and selection?

Compact Form Factors

Pre-integrated SoMs and SBCs deliver a critical small-form-factor design advantage for a broad array of applications. SoMs slightly larger than the size of a postage stamp and utilizing low-power and compact applications processors are ideal for mobile and lightweight applications (Fig. 2).

2. Often slightly larger than a postage stamp, SoMs like NXP’s i.MX6UL (measuring 29 × 29 × 3.5 mm), which integrates Digi’s ConnectCore, are well-suited for mobile and lightweight applications.

Fully featured SBCs with a PICO-ITX form factor (Fig. 3) are as small as an index card and deliver high-definition graphics and compute power that previously had to be rack-mounted. Advanced SBCs enable more efficient, rapid delivery of connected products and applications requiring multiple access points. Furthermore, they offer high levels of reliability and flexibility while facilitating development of key areas—including display capabilities—essential for powering IoT and M2M solutions.

Already tasked with fitting advanced performance and functionality into smaller and smaller footprints, designers now have a simplified design resource with these pre-validated systems.

Open Systems and Pre-Certifications

As pre-certified components, SoMs and SBCs solve the build-versus-buy dilemma by providing modular building-block solutions that offer interchangeable system profiles. Most SoMs and SBCs support industry-standard operating systems, including Linux, Android, and Microsoft Windows Embedded Compact. This reduces learning curves and costs while lowering risk and accelerating development activities.

Engineers invariably want to customize and refine their device designs as well as ensure that access to relevant software and hardware design components are available right from the start. They should verify that their chosen SoMs and SBCs provide full and royalty-free access to source code of the software platform support (Board Support Package).

On the hardware side, access to functional and verified reference designs is as important as choosing an established supplier that’s present both locally and globally with its own and partner resources.

Connectivity

The Internet of Things (IoT) is pervasive throughout applications in virtually all vertical markets. Fully integrated and complete connectivity options must be considered and designed into a product from the start—whether that be Wi-Fi connectivity to allow for product configuration or services, Bluetooth Classic for user device integration, Bluetooth Low Energy (BLE) for low-power sensors, or Ethernet for use cases mandating wired network connections.

With connectivity also comes the need for security and trusted communication. Increasingly, the next generation of SoMs and SBCs are equipped with BLE capabilities and fully pre-certified 802.11a/b/g/n/ac (2.4 and 5 GHz), software and driver support for enterprise-grade Wi-Fi security such as WPA/WPA2-Enterprise, cellular connectivity, and other options to ensure the device is able to integrate with larger computing grids. It also means that the SoM or SBC can be integrated into virtually any existing IT environment.

3. Digi’s index-card-sized ConnectCore 6 SBC, featuring a PICO-ITX form factor, offers high-definition graphics and high compute power.

Security Built-In

Embedded security is a critical design component for a growing number of connected IoT applications and devices. Evolving technology and network connectivity expose device manufacturers to significant new security risks and engineering challenges. A security framework from a reliable, trusted component manufacturer can provide a tested and fully integrated security framework designed for the long product lifecycle of embedded devices.

The best of these frameworks offer key features such as secure connections, authenticated boot, encrypted data storage, access-controlled ports, secure software updates, and seamless integration of the dedicated on-module Secure Element. With such frameworks, designers can get ahead of the complexity curve on device security by using a SoM and SBC platform designed for security from the start.

Summary

With increasingly compact and flexible form factors, commercial-off-the-shelf solutions like SoMs and SBCs are accelerating development cycles, reducing costs, and enabling in-house engineers to focus their scarce time and effort where it matters most. Furthermore, as the costs continue to fall and capabilities improve, SoMs and SBCs serve as ideal platforms for rapid, highly focused product design, enabling OEMs to increase the computing power and connectivity options for their products.

About the Author

Mike Rohrmoser

Director of Product Management for Embedded Systems

Mike Rohrmoser is the Director of Product Management for Embedded Systems at Digi International, where he’s responsible for the definition and delivery of Digi’s current embedded product solutions and future direction.